Filtering elements for hydraulically squeezing and extruding out mud cake

A filter element and mud cake technology, applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of reduced dehydration effect of filter elements, complicated manufacturing and installation, and reduced dehydration efficiency of filter elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The filter element of the present invention will be further described below in conjunction with the accompanying drawings.

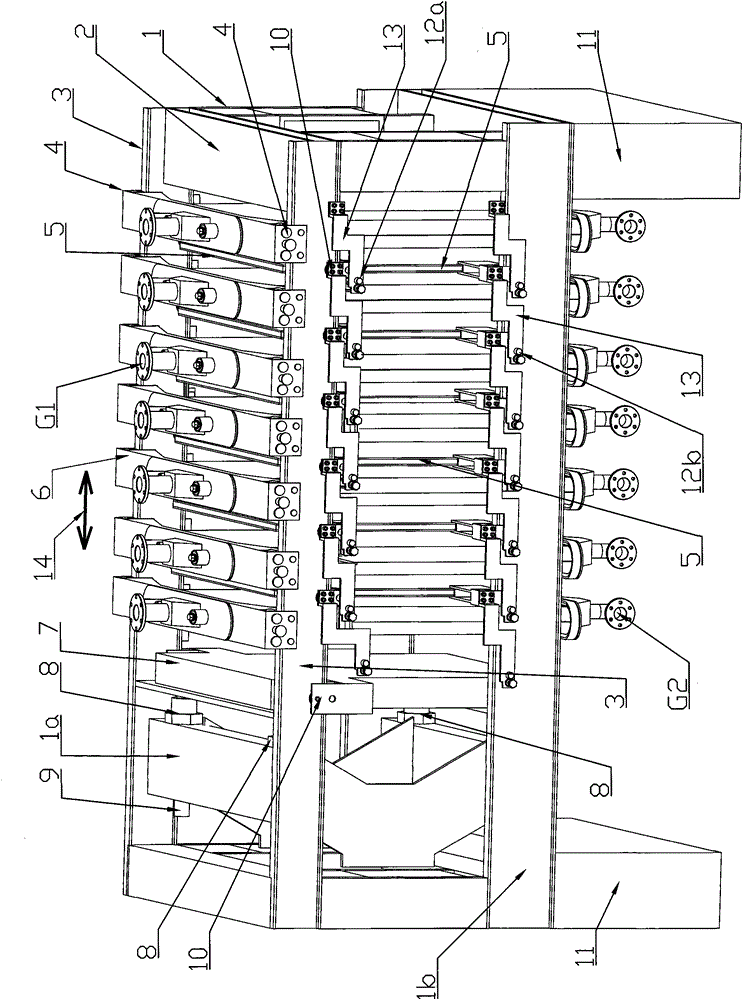

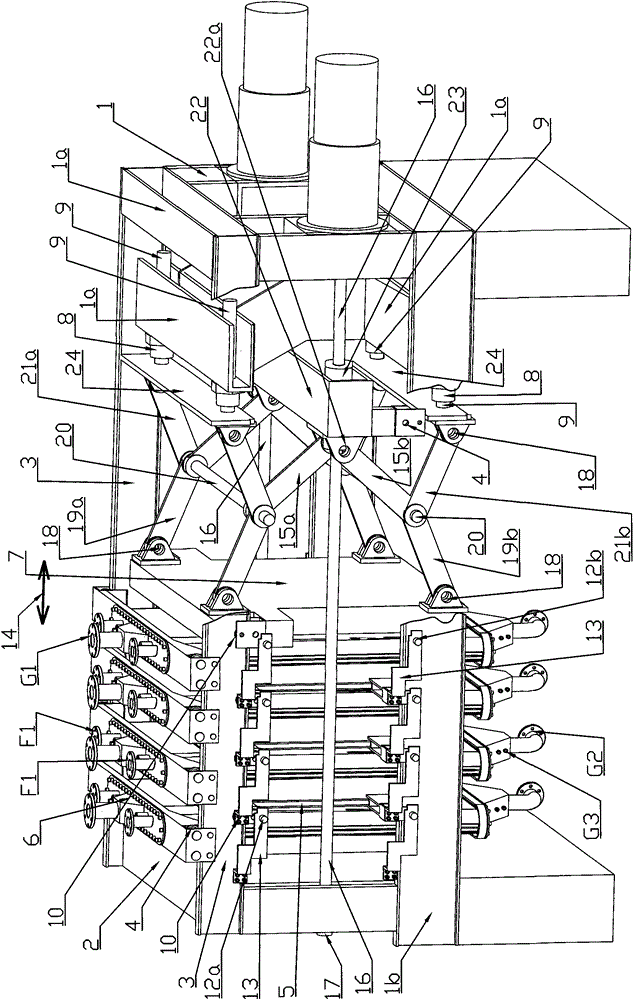

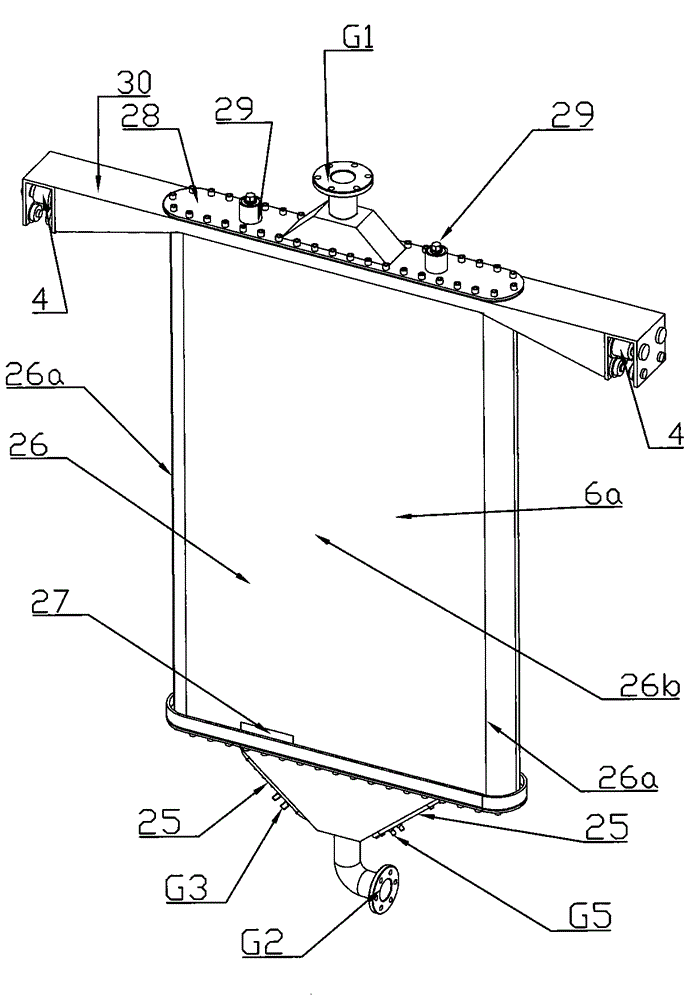

[0076] exist Figures 1 to 15 , 17 and 20, a general embodiment 1 of the filter element of the present invention and its installation in a flexible tube press is shown.

[0077] exist figure 1 There are 7 filter elements in the flexible tube press. The flexible tube press mainly includes a pumping device, a filter assembly, a pressure-bearing device, a dry sludge conveying device, a filtrate discharge system, a pipeline system and a control system, and is integrated into a complete set of mechanical and electrical integration, automatic solid-liquid separation and comprehensive treatment; The pressure device includes a compression assembly and a pressure bearing structure; the pressure bearing structure includes a pressure plate 7, a frame guide rail 3, a frame 1 and a pressure bearing plate, and the pressure bearing plate includes an intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com