Modified quartz sand andmodification method thereof

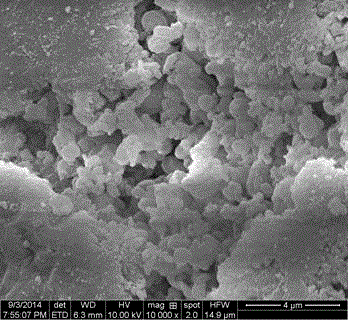

A quartz sand and modification technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of changing the composition of quartz sand, reuse of quartz sand adsorbent, regeneration and negative effects of recycling, etc. To achieve the effect of convenient recycling, easy realization, and increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

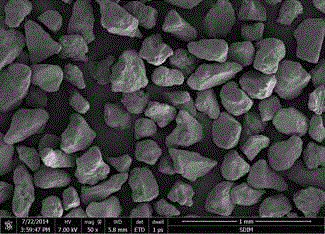

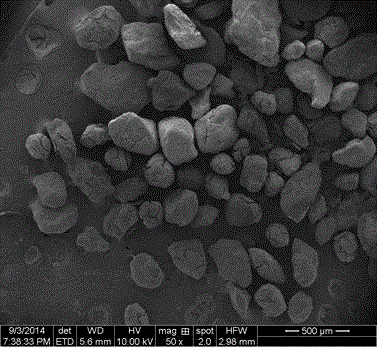

Image

Examples

Embodiment 1

[0038] 1. Mix 0.3g P123 and 40 mlH2O, dissolve evenly at 25°C, then add 2g of quartz sand;

[0039] 2. Add 1ml of water glass to the mixture in step 1, stir evenly, then add 4ml of 1M hydrochloric acid solution under rapid stirring, and stir evenly; or add 4ml of 1M hydrochloric acid solution, stir well, then add 1ml of water glass, stir well;

[0040] 3. Transfer the reaction solution in step 2 to a shaker, and react at 25°C for 12 hours under the condition of gyrating and shaking (rotating frequency 200rpm), wash and filter after the reaction, dry the precipitate at 90°C for 3h, and then calcinate at 550°C for 6h , to obtain modified quartz sand samples. The specific surface area of the obtained sample is shown in the table below:

[0041]

Embodiment 2

[0043] Take appropriate weight of P123 according to the table below, mix P123 with 40 ml H2O, dissolve evenly at 25°C, then add 2g of quartz sand and 1ml of water glass, stir at 25°C for 15min, then add 4ml under rapid stirring 1M hydrochloric acid solution; move the reaction solution to a shaker, and react at 60°C for 12h under the condition of gyrating shaking (rotating frequency 200rpm), wash and filter after the reaction, dry the precipitate at 90°C for 3h, and then calcinate at 550°C for 6h , to obtain modified quartz sand samples. The obtained samples were tested for specific surface area. The amount of P123 and the specific surface area of the obtained sample are shown in the table below:

[0044]

Embodiment 3

[0046] Mix 0.3g P123 and 40 ml H2O, dissolve evenly at 25°C, then add 2g quartz sand and 1ml water glass, stir at 25°C for 15min, then add different volumes of 1M hydrochloric acid to dissolve under rapid stirring; The reaction solution was transferred to a shaker, and reacted at 25°C for 12 hours under the condition of gyrating and shaking (rotating frequency 200rpm), washed and filtered after the reaction, and the precipitate was dried at 90°C for 3h, and then calcined at 550°C for 6h to obtain a modified quartz sand sample . The obtained samples were tested for specific surface area. The consumption of hydrochloric acid and the specific surface area of gained sample are shown in the table below:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com