A kind of preparation method for the solid catalyst of synthetic propylene carbonate

A solid catalyst, propylene carbonate technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problems of difficult catalyst recovery and high cost, and achieve solid Good loading effect, reduced preparation cost, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

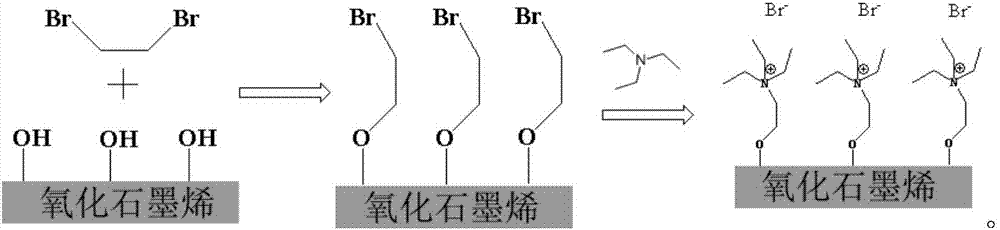

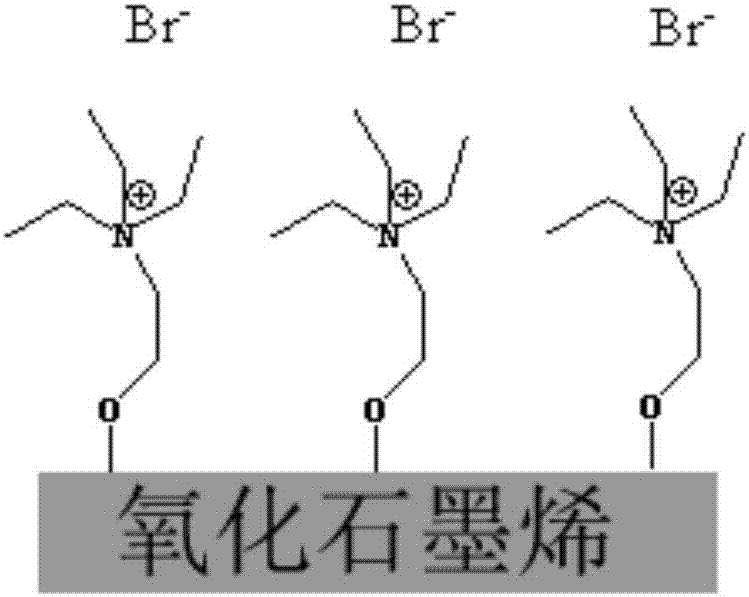

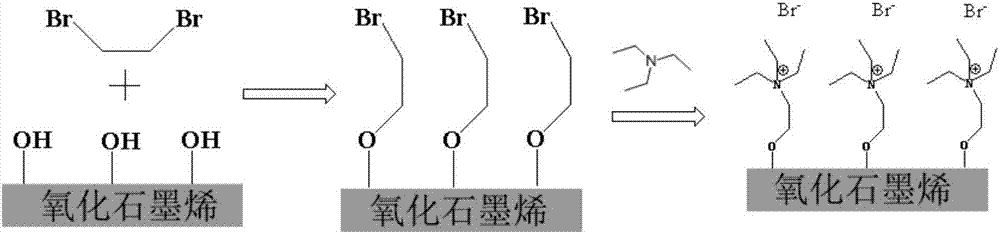

Method used

Image

Examples

Embodiment 1

[0018] Add graphene oxide into toluene, wherein the mass ratio of toluene to graphene oxide is 100:1, stir magnetically for 30 minutes, heat up to 30°C, add 1,2-dibromoethane dropwise, wherein 1,2-dibromoethane The mass ratio of ethane to graphene oxide is 1:1, and the reaction is continued for 4h; triethylamine is then added dropwise to the above reaction system, and the molar ratio of triethylamine to 1,2-dibromoethane is 1:1, Continue to react for 2 hours after the drop; after the reaction, it is centrifuged, washed with toluene, and dried. The resulting catalyst was designated CAT-1.

Embodiment 2

[0020] Add graphene oxide into toluene, wherein the mass ratio of toluene to graphene oxide is 100:1, stir magnetically for 30 minutes, heat up to 60°C, add 1,2-dibromoethane dropwise, wherein 1,2-dibromo The mass ratio of ethane to graphene oxide is 1:1, and the reaction is continued for 4h; triethylamine is then added dropwise to the above reaction system, and the molar ratio of triethylamine to 1,2-dibromoethane is 1:1, Continue to react for 2 hours after the drop; after the reaction, it is centrifuged, washed with toluene, and dried. The resulting catalyst is designated CAT-2.

Embodiment 3

[0022] Add graphene oxide into toluene, wherein the mass ratio of toluene to graphene oxide is 100:1, stir magnetically for 30 minutes, heat up to 50°C, add 1,2-dibromoethane dropwise, wherein 1,2-dibromo The mass ratio of ethane to graphene oxide is 1:1, and the reaction is continued for 8h; triethylamine is then added dropwise to the above reaction system, and the molar ratio of triethylamine to 1,2-dibromoethane is 1:1, Continue to react for 6 hours after the drop; after the reaction, it is centrifuged, washed with toluene, and dried. The resulting catalyst was designated CAT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com