Ethylenediamine functionalized three-dimensional ordered mesopore organosilicone immobilized Pd(II) catalyst

A Mesoporous Silicone, Three-Dimensional Ordered Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

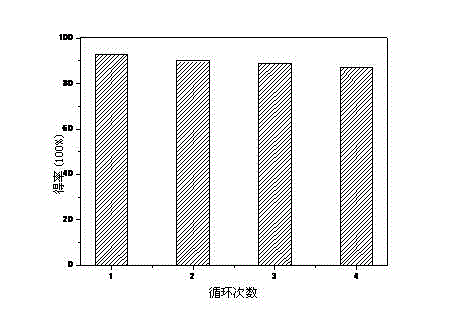

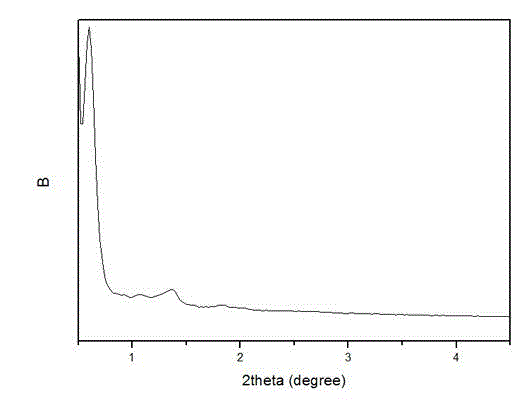

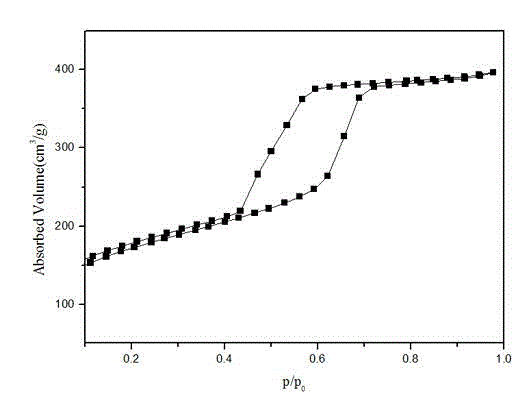

[0026] Example 1: Preparation of ethylenediamine-functionalized three-dimensional ordered mesoporous organosilicon-immobilized Pd(II) catalyst according to the following steps

[0027] (1) Mix surfactant, alcohol and hydrochloric acid to make an aqueous solution with surfactant concentration of 3.8 mM, alcohol concentration of 0.32M, and HCl concentration of 0.11M. o C mixed evenly; add 1, 2-bistriethoxysilylbenzene, prepolymerize for 50min; then add ethylenediamine bridged silane, continue to react for 28 h; o C aging for 80 h; wherein, in step (1), the molar ratio of 1,2-bistriethoxysilylbenzene to ethylenediamine bridged silane is 5:1; the surfactant is P123; the The ethylenediamine bridged silane is two [3-(trimethoxysilyl) propyl] ethylenediamine;

[0028] (2) The solid obtained in step (1) is extracted to remove the surfactant, washed with alkali, and dried to obtain a three-dimensional ordered mesoporous organosilicon (DA-PMO) functionalized with ethylenediamine; where...

Embodiment 2

[0031] Example 2: Prepare ethylenediamine-functionalized three-dimensional ordered mesoporous organosilicon-immobilized Pd(II) catalyst according to the following steps

[0032] (1) Mix surfactant, alcohol and hydrochloric acid to make an aqueous solution with surfactant concentration of 4.0 mM, alcohol concentration of 0.4 M, and HCl concentration of 0.12 M. o C mix well; add 1, 2-bistriethoxysilylbenzene, pre-polymerize for 65min; then add ethylenediamine bridged silane, continue to react for 25 h; o C aging for 75h; wherein, in step (1), the molar ratio of 1,2-bistriethoxysilylbenzene to ethylenediamine bridged silane is 30:1; the surfactant is P123; the The ethylenediamine bridged silane is bis[3-(triethoxysilyl)propyl]ethylenediamine;

[0033] (2) The solid obtained in step (1) is extracted to remove the surfactant, washed with alkali, and dried to obtain a three-dimensional ordered mesoporous organosilicon (DA-PMO) functionalized with ethylenediamine; wherein, in step...

Embodiment 3

[0036] Example 3: Preparation of ethylenediamine-functionalized three-dimensional ordered mesoporous organosilicon immobilized Pd(II) catalyst according to the following steps

[0037] (1) Mix surfactant, alcohol and hydrochloric acid to make an aqueous solution with surfactant concentration of 4.2 mM, alcohol concentration of 0.45 M, and HCl concentration of 0.13 M. o C mix well; add 1, 2-bistriethoxysilylbenzene, pre-polymerize for 50min; then add ethylenediamine bridged silane, continue to react for 22h; o C aging for 70h; wherein, in step (1), the molar ratio of 1,2-bistriethoxysilylbenzene to ethylenediamine bridged silane is 60:1; the surfactant is P123; the The ethylenediamine bridged silane is bis[3-(trimethoxysilyl)propyl]ethylenediamine;

[0038] (2) The solid obtained in step (1) is extracted to remove the surfactant, washed with alkali, and dried to obtain a three-dimensional ordered mesoporous organosilicon (DA-PMO) functionalized with ethylenediamine; wherein, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com