Abrasion-resisting lamination double-metal composite material and manufacturing method thereof

A composite material and manufacturing method technology, applied in the direction of manufacturing tools, metal layered products, metal processing equipment, etc., can solve the problems of falling off, affecting the performance and life of pipes, increasing manufacturing and maintenance costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

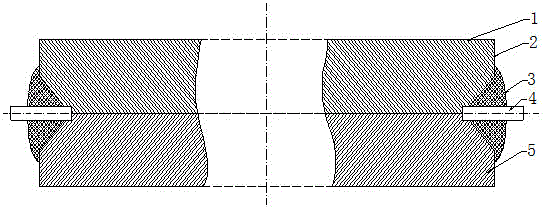

Image

Examples

Embodiment 1

[0052] Step (1), selection of billet raw materials: ordinary carbon steel is used for the base material, and medium-carbon low-alloy wear-resistant steel is selected for the wear-resistant cladding material; the thickness of the wear-resistant cladding material is 85mm, and the thickness of the base material is 68mm; the base material and The wear-resistant clad material is cut according to the following size requirements: the base material and the wear-resistant clad material are cut into rectangles, and the width deviation of the two is ≤3mm, and the diagonal deviation is ≤10mm;

[0053] Step (2), selection of the interface of the wear-resistant cladding material: detect the depth of the decarburization layer of the wear-resistant cladding material, and select the deeper side of the decarburization layer as the bonding interface of the wear-resistant cladding material combined with the base material , the other side is the non-bonding side;

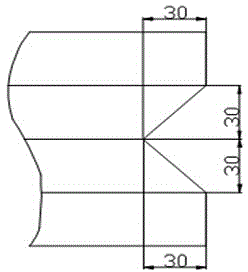

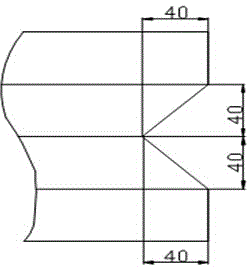

[0054] Step (3), the groove sett...

Embodiment 2

[0072] Step (1), selection of billet raw materials: low-alloy steel is used for the base material, and high-carbon low-alloy wear-resistant steel is used for the wear-resistant cladding material; the thickness of the wear-resistant cladding material is 80mm, and the thickness of the base material is 65mm; The wear-resistant cladding material is cut according to the following size requirements: the base material and the wear-resistant cladding material are cut into rectangles, and the width deviation of the two is ≤3mm, and the diagonal deviation is ≤10mm;

[0073]Step (2), selection of the interface of the wear-resistant cladding material: detect the depth of the decarburization layer of the wear-resistant cladding material, and select the deeper side of the decarburization layer as the bonding interface of the wear-resistant cladding material combined with the base material , the other side is the non-bonding side;

[0074] Step (3), the groove setting of the billet raw mater...

Embodiment 3

[0092] Step (1), selection of billet raw materials: low-alloy steel is used for the base material, and medium-carbon low-alloy wear-resistant steel is selected for the wear-resistant cladding material; the thickness of the wear-resistant cladding material is 86mm, and the thickness of the base material is 69mm; The wear-resistant cladding material is cut according to the following size requirements: the base material and the wear-resistant cladding material are cut into rectangles, and the width deviation of the two is ≤3mm, and the diagonal deviation is ≤10mm;

[0093] Step (2), selection of the interface of the wear-resistant cladding material: detect the depth of the decarburization layer of the wear-resistant cladding material, and select the deeper side of the decarburization layer as the bonding interface of the wear-resistant cladding material combined with the base material , the other side is the non-bonding side;

[0094] Step (3), the groove setting of the billet ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com