Preparation method of 42% methylhydrazine aqueous solution

A technology of methylhydrazine and aqueous solution, which is applied in the field of chemical distillation, can solve the problems of large heat consumption, high content of methylhydrazine in wastewater, and high production costs, and achieve the effect of low energy consumption for separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

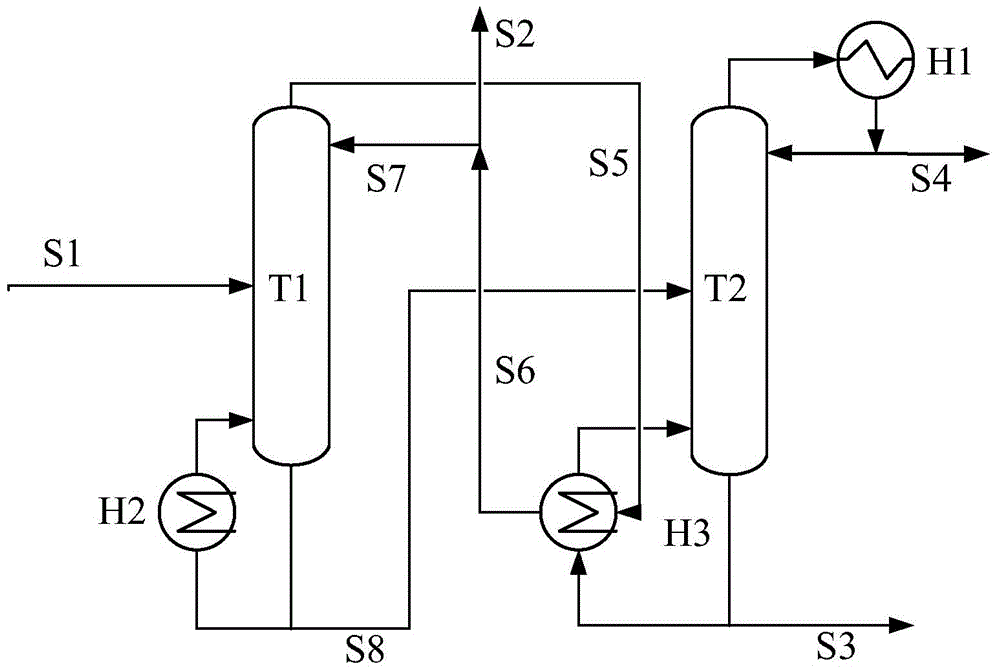

[0026] according to figure 1 The process flow diagram shown implements the present invention, and the raw material flow S1 of 3043kg / h that temperature is 50 ℃ is sent into the middle part of the first rectifying tower T1 tower, raw material composition: water, 97.63%; Methylhydrazine: 2.37%.

[0027] The first rectification tower T1 is operated at 300kPa, the reflux ratio is 1, the top of the T1 tower is produced as water, the temperature at the top of the tower is 133°C, the bottom of the T1 tower is concentrated liquid of methylhydrazine, and the temperature of the bottom of the tower is 134°C; The second rectification tower T2 operates at 100kPa, the reflux ratio is 3, the top of the T2 tower is produced as water, the temperature at the top of the tower is 99 ° C, and the T2 tower is produced as a methylhydrazine aqueous solution with a mass fraction of 42.59% of methylhydrazine. The temperature of the tower kettle is 105°C. The logistics composition in Example 1 is shown...

Embodiment 2

[0035] according to figure 1 The process flow diagram shown implements the present invention, and the raw material flow S1 of 3043kg / h that temperature is 50 ℃ is sent into the middle part of the first rectifying tower T1 tower, raw material composition: water, 98.0%; Methylhydrazine: 2.0%.

[0036] The first rectification tower T1 is operated at 400kPa, the reflux ratio is 1, the top of the T1 tower is produced as water, and the temperature at the top of the tower is 143°C, and the output from the bottom of the T1 tower is methylhydrazine concentrate, and the temperature of the bottom of the tower is 144°C ; The second rectification tower T2 operates at 200kPa, the reflux ratio is 3, the top of the T2 tower is produced as water, and the temperature at the top of the tower is 120°C; the production of the T1 tower is methylhydrazine with a mass fraction of 42.09% of methylhydrazine Aqueous solution, the temperature of the tower kettle is 126°C.

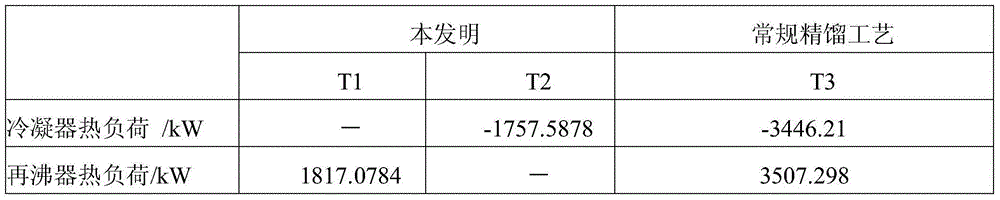

[0037] In order to embody the ...

Embodiment 3

[0044] according to figure 1 The process flow sheet shown implements the present invention, and the temperature is that the raw material flow S1 of 3043kg / h of 50 ℃ is sent into the middle part of the first rectifying tower T1 tower, raw material composition: water, 97.5%; Methylhydrazine: 2.5%.

[0045] The first rectification tower T1 is operated at 400kPa, the reflux ratio is 1, the top of the T1 tower is produced as water, and the temperature at the top of the tower is 143°C, and the output from the bottom of the T1 tower is methylhydrazine concentrate, and the temperature of the bottom of the tower is 144°C ; The second rectification tower T2 is operated at 100kPa, the reflux ratio is 3, the top of the T2 tower is produced as water, and the temperature at the top of the tower is 99°C; the production of the T1 tower is methylhydrazine with a mass fraction of 42.49%. Aqueous solution, the temperature of the tower kettle is 105°C.

[0046] In order to embody the advantages ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com