Preparation method of Plecanatide

A prika, crude peptide technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of difficult separation and purification, methods to be improved, complex components, etc., and achieve considerable economic and practical value and cost. Low, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

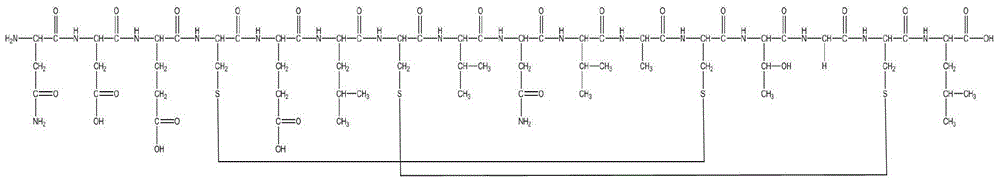

Image

Examples

Embodiment 1

[0044] Weigh 10 g (5.1 mmol) of Fmoc-Leu-king resin with a degree of substitution of 0.51 mmol / g, add it to the solid phase reactor, wash with DMF three times, and swell for 3 hours. The piperidine:DMF solution with a volume ratio of 1:4 was added to the reactor for reaction, and after the reaction, it was washed twice with DCM, and washed with DMF four times. Weigh 6.34g of Fmoc-Cys(Acm)-OH, 2.07g of HOBt, and 2.37mL of DIC to dissolve in DMF solution, mix well and add to the reactor, and react at room temperature for 2h. The ninhydrin color reaction controls the end point. The resin is transparent and colorless to indicate the end of the reaction. If the color develops, the reaction continues until colorless. After the reaction was completed, DCM was washed twice, and DMF was washed four times.

[0045] Repeat the above steps, follow the sequence of deprotection, coupling Fmoc-Gly-OH, Fmoc-Thr(tBu)-OH, Fmoc-Cys-(Mmt)-OH, Fmoc-Ala-OH, Fmoc-Val-OH , Fmoc-Asn(Trt)-OH, Fmoc-Val-O...

Embodiment 2

[0051] Weigh 10 g (2 mmol) of Fmoc-Leu-king resin with a degree of substitution of 0.2 mmol / g and add it to the solid phase reactor. After DMF was washed 3 times, it swelled for 3 hours. The piperidine:DMF solution with a volume ratio of 1:4 was added to the reactor for reaction, and after the reaction, it was washed twice with DCM, and washed with DMF four times. Weigh 1.24g of Fmoc-Cys(Acm)-OH, 0.406g of HOBt, and 0.465mL of DIC to dissolve in DMF solution, mix well and add to the reactor, and react at room temperature for 2h. The ninhydrin color reaction controls the end point. The resin is transparent and colorless to indicate the end of the reaction. If the color develops, the reaction continues until colorless. After the reaction was completed, DCM was washed twice, and DMF was washed four times.

[0052] Repeat the above steps, follow the sequence of deprotection, coupling Fmoc-Gly-OH, Fmoc-Thr(tBu)-OH, Fmoc-Cys-(Mmt)-OH, Fmoc-Ala-OH, Fmoc-Val-OH , Fmoc-Asn(Trt)-OH, Fmo...

Embodiment 3

[0058] Weigh 10 g (6 mmol) of Fmoc-Leu-king resin with a degree of substitution of 0.6 mmol / g, add it to the solid phase reactor, wash with DMF three times, and swell for 3 hours. The piperidine:DMF solution with a volume ratio of 1:4 was added to the reactor for reaction, and after the reaction, it was washed twice with DCM, and washed with DMF four times. Weigh 7.46g of Fmoc-Cys(Acm)-OH, 2.44g of HOBt, and 2.79mL of DIC, and dissolve them in DMF solution, mix well and add to the reactor, and react at room temperature for 2h. The ninhydrin color reaction controls the end point. The resin is transparent and colorless to indicate the end of the reaction. If the color is developed, the reaction continues until colorless. After the reaction was completed, DCM was washed twice, and DMF was washed four times.

[0059] Repeat the above steps, follow the sequence of deprotection, coupling Fmoc-Gly-OH, Fmoc-Thr(tBu)-OH, Fmoc-Cys-(Mmt)-OH, Fmoc-Ala-OH, Fmoc-Val-OH , Fmoc-Asn(Trt)-OH, Fm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com