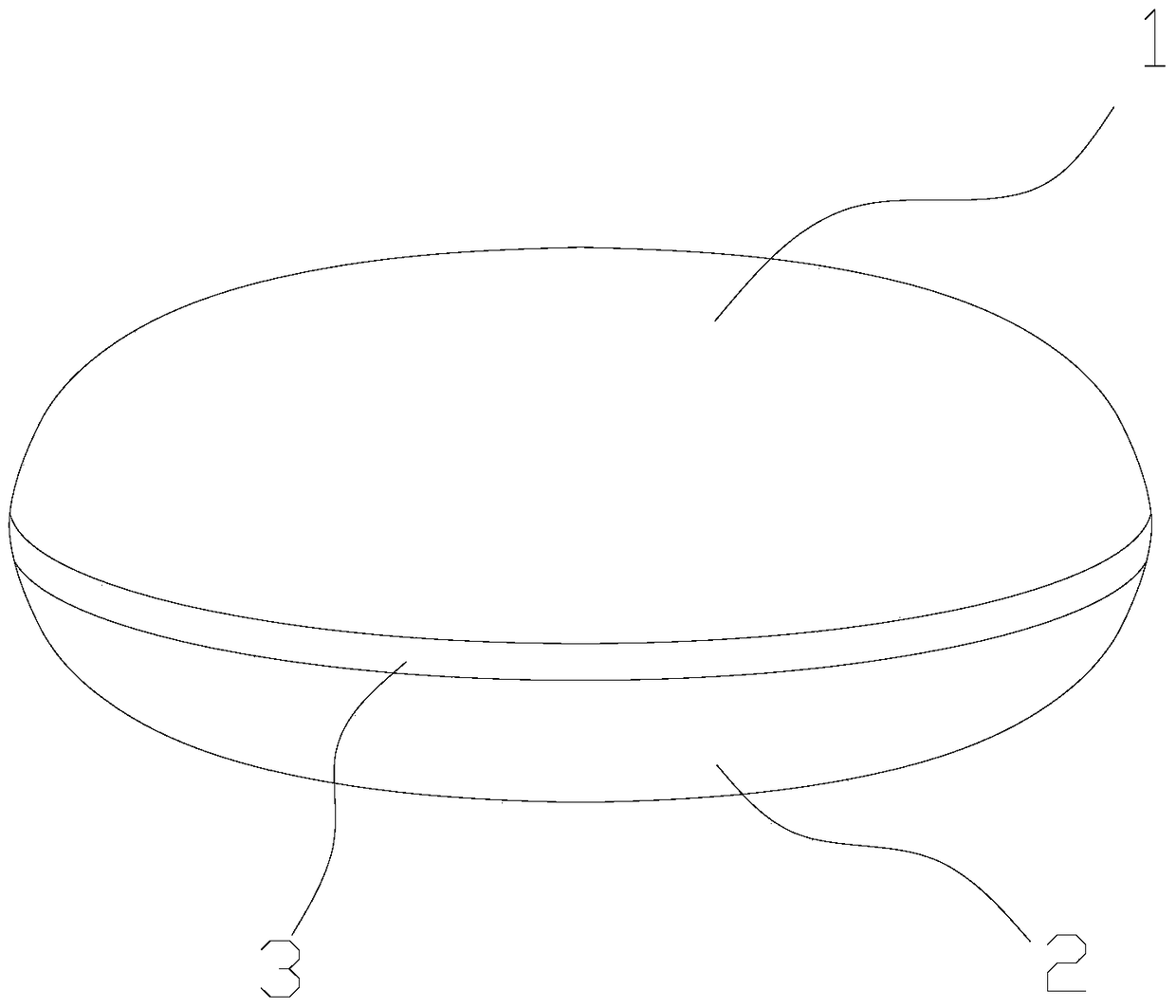

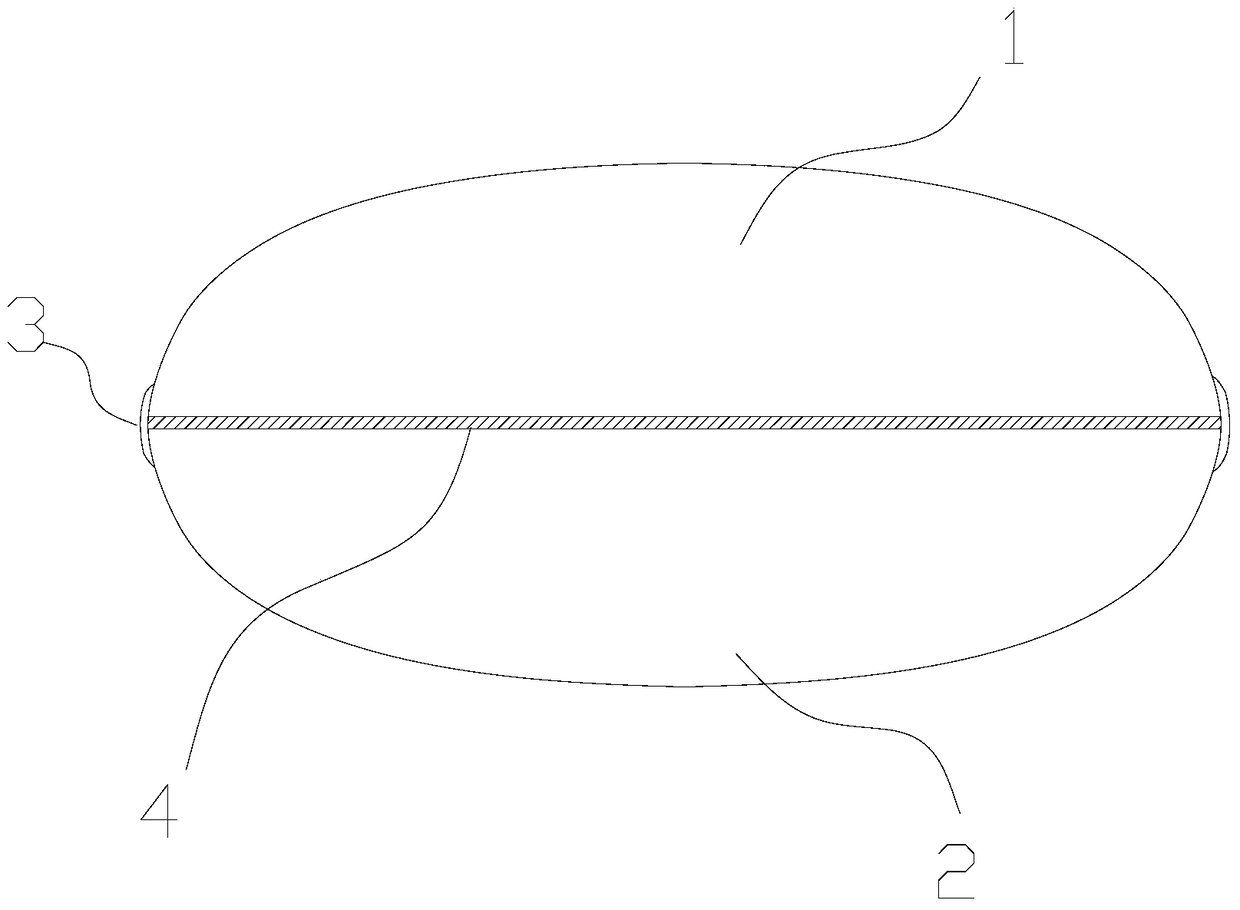

Bread-shaped porous polyurethane foam

A technology for polyurethane foam and bread, applied in the field of polyurethane foam, can solve the problems of outflow, difficult cosmetic composition, poor hand comfort, etc., and achieve the effects of strong hand comfort, convenient use and moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

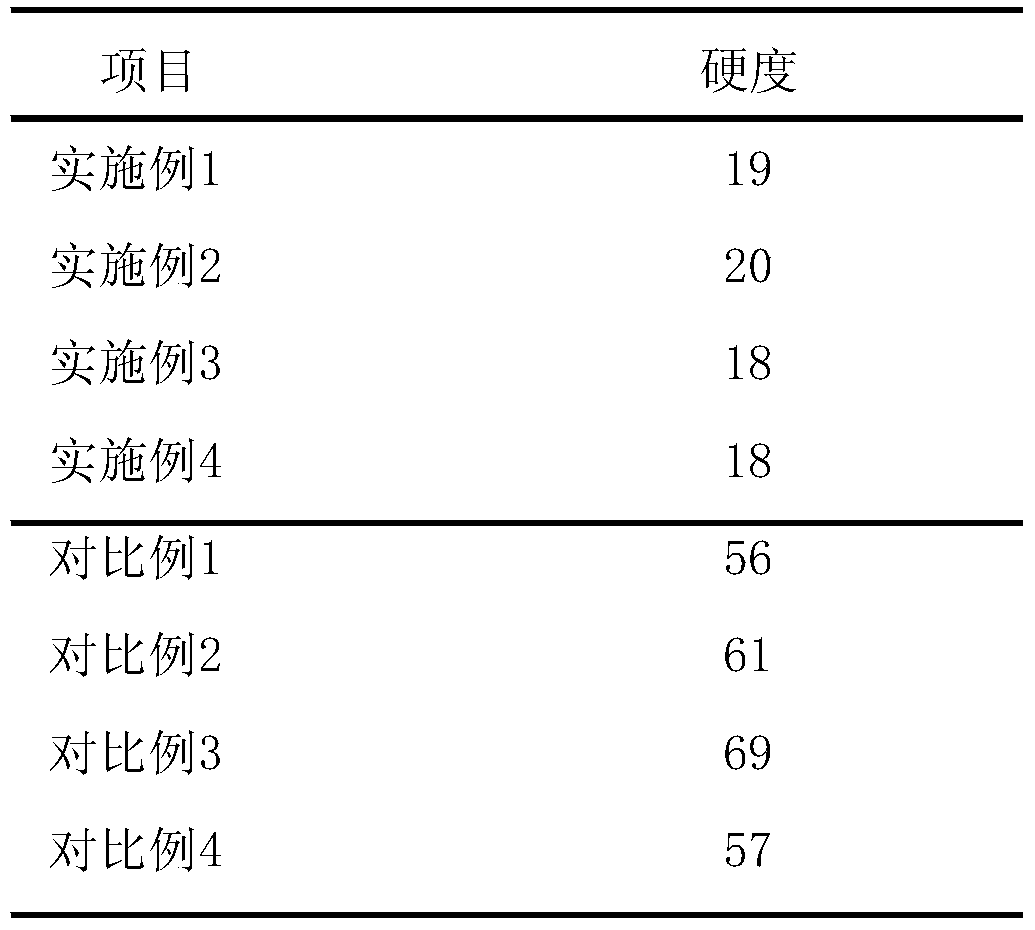

Examples

Embodiment 1

[0024] This embodiment relates to a bread-shaped porous polyurethane foam, which is obtained through the following steps:

[0025] Step 1, preparation of the prepolymer component: weigh polytetrahydrofuran ether polyol (PTMG2000, BASF product, molecular weight is 2000, average functionality is 2) 100g and 1,4-butanediol 3g, place in the reaction kettle, Heat up to 105°C and dehydrate under vacuum (-0.09MPa) for 1.5 hours, then cool down to 45°C, add 30g of toluene diisocyanate (TDI), slowly heat up to 80°C within 30 minutes, keep the temperature for 2.5 hours, cool down to 50°C and discharge , sealed and preserved;

[0026] Step 2, preparation of the foaming agent component: Weigh 1.0 g of silicone surfactant Niax Y-10366 and add it to 100 g of distilled water (1 mol / L hydrochloric acid to adjust the pH value to 2.8), stir evenly, and seal and store;

[0027] Step 3: Weigh 100g of prepolymer components and 70g of blowing agent components, quickly mix them uniformly, pour them...

Embodiment 2

[0029] This embodiment relates to a bread-shaped porous polyurethane foam, which is obtained through the following steps:

[0030] Step 1, preparation of prepolymer components: Weigh 100 g of polyethylene oxide ether polyol and 4 g of diethylene glycol, place in a reaction kettle, heat up to 100 ° C and dehydrate under vacuum (-0.09 MPa) for 1.5 hour, then cool down to 45°C, add 28g of toluene diisocyanate (TDI), slowly heat up to 80°C within 40min, keep warm for 2.5 hours, cool down to 50°C and discharge, sealed and stored;

[0031] Step 2, preparation of the blowing agent component: Weigh 1.5g of silicone surfactant Niax Y-10366 and add it to 100g of distilled water (1mol / L hydrochloric acid to adjust the pH value to 3.2), stir evenly, and seal and store;

[0032] Step 3: Weigh 100g of prepolymer components and 90g of blowing agent components, quickly mix them uniformly, pour them into a mold, and mature them for 3 minutes to obtain a porous polyurethane foam material.

Embodiment 3

[0034] This embodiment relates to a bread-shaped porous polyurethane foam, which is obtained through the following steps:

[0035] Step 1, preparation of the prepolymer component: Weigh 100 g of polyethylene glycol and 5 g of dipropylene glycol, place them in a reaction kettle, heat up to 100° C. for vacuum (-0.095 MPa) dehydration for 1.5 hours, and then cool down to 50 ℃, add 26g of toluene diisocyanate (TDI), slowly raise the temperature to 65 ℃ within 20 minutes, keep the temperature for 2.0 hours, cool down to 50 ℃ and discharge, sealed and stored;

[0036] Step 2, preparation of foaming agent components: Weigh 0.5 g of silicone surfactant Niax Y-10366 and add it to 100 g of distilled water (1 mol / L hydrochloric acid to adjust the pH value to 3.9), stir evenly, and seal and store;

[0037] Step 3: Weighing 100g of the prepolymer component and 50g of the blowing agent component and quickly mixing them uniformly, pouring them into a mold, and curing them for 3 minutes to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com