Recovery and refining method of solvents and monomers in the industrial production of rare earth-isoprene rubber

A rare earth isoprene rubber and refining method technology, which is applied in the field of recovery and refining of solvents and monomers, can solve problems such as the impact of increased vaporization on operational stability, separation and consumption of monomers and solvents, and achieve improvements in heavy component impurities and Serious entrainment of polymerization inhibitor and effect of reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

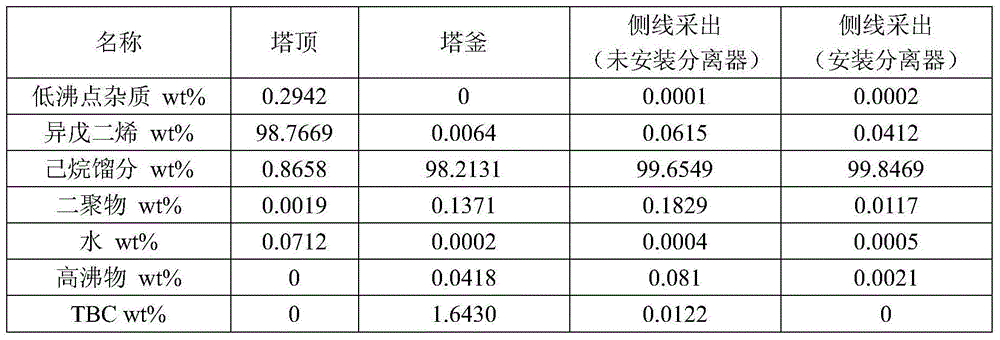

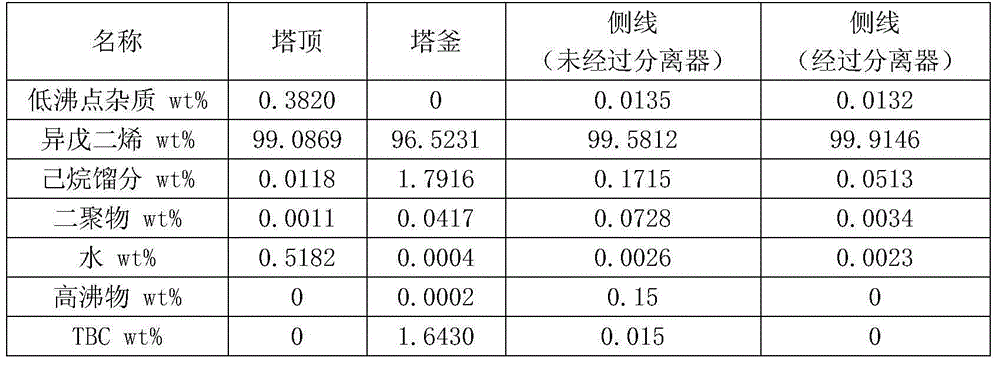

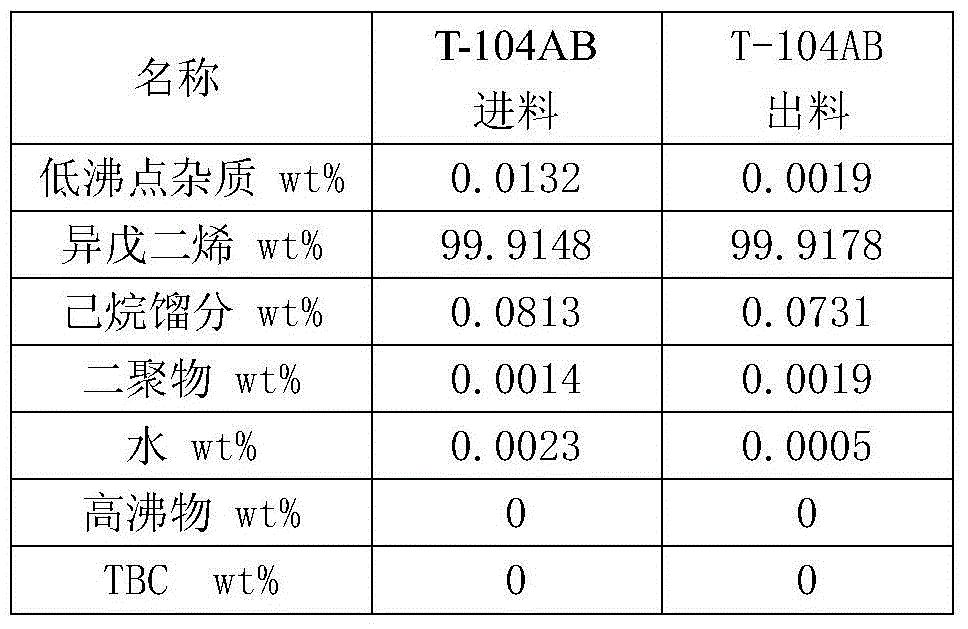

Embodiment 1

[0019] (1) The composition of the recovered oil phase is shown in Table 1. Control a certain flow rate and enter the solvent recovery tower for separation. Light components such as hexane, isoprene and trace water at the top of the tower are condensed and cooled by the condenser of the recovery tower before being recovered. The tower top reflux tank, and then a part of the recovered isoprene enters the isoprene refining tower together with fresh isoprene for isoprene refining (when the recovered isoprene is recycled too many times, the impurity content exceeds the specified When the value is high, all or part of the recovered isoprene will be sent out of the boundary, and will not enter the isoprene refining tower for refining together with fresh isoprene. The free water at the bottom of the tank is released regularly, and the content of heavy components such as hexane at the top of the recovery tower is controlled to be ≤1%;

[0020] (2) Take out the gaseous hexane fraction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com