Corrosion process of low-voltage hard high-specific capacitance aluminum electrode foil

A technology of aluminum electrode foil and process method, which is applied in the field of aluminum foil manufacturing, can solve the problems of large investment in variable frequency power supply equipment, large AC waveform distortion, and high requirements for the use environment, and achieve low equipment investment, high performance specific volume, and low operation and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

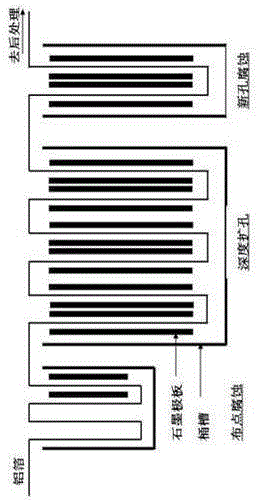

[0027] A corrosion process method for low-voltage hard high-volume aluminum electrode foil includes the following steps:

[0028] 1. Spot corrosion: Firstly, the domestically made 95μm hard light foil after degreasing treatment is immersed in the spot corrosion liquid for 45 seconds, and then 0.3A / cm2 current density is applied for 16 seconds. The main body of the spot corrosion liquid is 18wt% hydrochloric acid, 0.8wt% sulfuric acid, the temperature is maintained at 40℃;

[0029] 2. Deep hole expansion corrosion: deep corrosion is carried out on the basis of pitting corrosion in the previous process. With the expansion of pitting corrosion, the main body of the corrosion liquid is 20wt% hydrochloric acid, 1.2wt% sulfuric acid, and 6g / L oxalic acid is added. , 300mg / L thiourea, 150mg / L ferric chloride, the temperature is maintained at 33℃, the average current density of 0.15A / cm2 is applied during the power-on process, and the action time is 360 seconds;

[0030] 3...

Example Embodiment

[0032] Example 2

[0033] A corrosion process method for low-voltage hard high-volume aluminum electrode foil includes the following steps:

[0034] 1. Spot corrosion: Firstly, the domestically made 95μm hard light foil after degreasing treatment is immersed in a spot corrosion liquid for 30 seconds, and then a current density of 0.3A / cm2 is applied for 12 seconds. The main body of the spot corrosion liquid is 18wt% hydrochloric acid, 0.8wt% sulfuric acid, the temperature is maintained at 35℃;

[0035] 2. Deep hole expansion corrosion: deep corrosion is carried out on the basis of pitting corrosion in the previous process. With the expansion of pitting corrosion, the main body of the corrosion liquid is 20wt% hydrochloric acid, 1.2wt% sulfuric acid, and 6g / L oxalic acid is added. , 300mg / L thiourea, 150mg / L ferric chloride, the temperature is maintained at 30℃, an average current density of 0.15A / cm2 is applied during the power-on process, and the action time is 300 seconds;

[0036]...

Example Embodiment

[0038] Example 3

[0039] A corrosion process method for low-voltage hard high-volume aluminum electrode foil includes the following steps:

[0040] 1. Spotting corrosion: Firstly, the domestically made 95μm hard light foil after degreasing treatment is immersed in the spotting corrosion liquid for 60 seconds, and then 0.3A / cm2 current density is applied for 20 seconds. The main body of the spotting corrosion liquid is 18wt% hydrochloric acid, 0.8wt% sulfuric acid, the temperature is maintained at 45℃;

[0041] 2. Deep hole expansion corrosion: deep corrosion is carried out on the basis of pitting corrosion in the previous process. With the expansion of pitting corrosion, the main body of the corrosion liquid is 20wt% hydrochloric acid, 1.2wt% sulfuric acid, and 6g / L oxalic acid is added. , 300mg / L thiourea, 150mg / L ferric chloride, the temperature is maintained at 35°C, an average current density of 0.15A / cm2 is applied during the power-on process, and the action time is 400 second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion amount | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap