Circulating iodine adsorber performance test method and device

A technology of iodine adsorber and inspection device, which is applied in the performance inspection and device field of circulating iodine adsorber, which can solve the problems that the absolute water content cannot be removed, the motor is prone to heat, and the safety level is low, so as to reduce the detection balance time and save electric energy , the effect of protecting the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

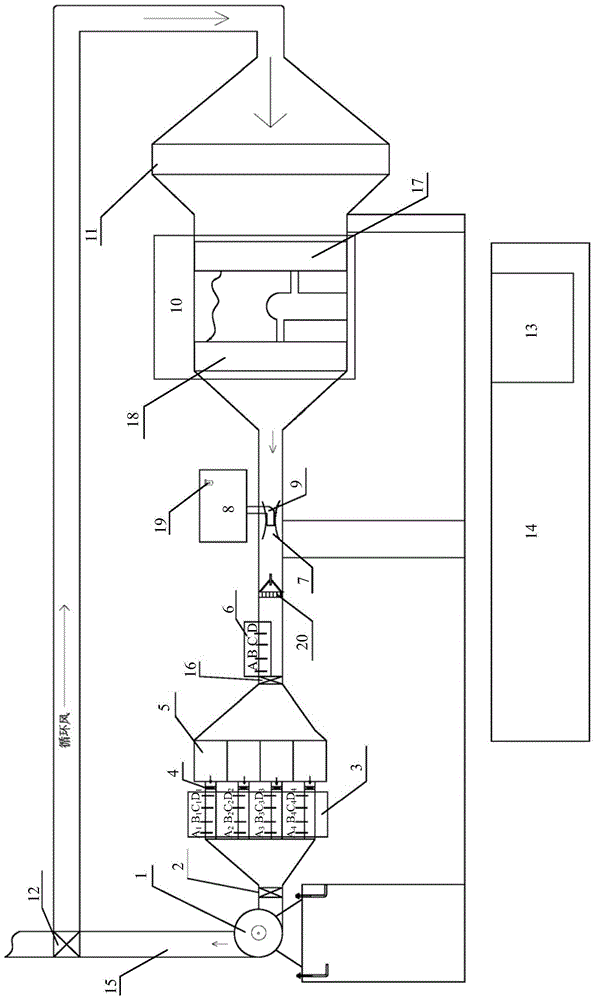

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation process.

[0023] The performance testing method of the iodine adsorber provided by the invention forms a circulating air flow between the inlet and outlet of the tested iodine adsorber, uses the circulating air flow to reduce emissions, and is beneficial to the balance of temperature and humidity. The frequency regulator and fine-tuning technology of the FM fan are used to accurately adjust the flow rate of the circulating air flow. The heat pump system can automatically control the humidity of the airflow, and make the relative humidity of the airflow on both sides of the inlet and outlet of the iodine adsorber reach the same in a short period of time, which is conducive to the relative stability of the water content before and after the inspection of the iodine adsorber to stabilize its iodine removal performance. , At the same time save time and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com