Exposure system and exposure process

An exposure system and process technology, which is applied in microlithography exposure equipment, photo-plate-making process of pattern surface, photo-plate-making process exposure device, etc., can solve reliability test failure, destruction, poor optical performance of liquid crystal display panel, etc. problem, to reduce the effect of optical performance or reliability test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

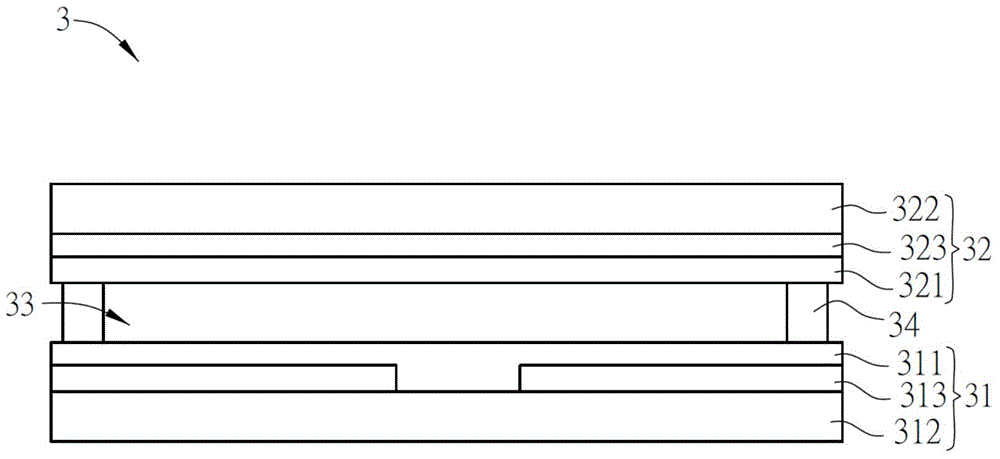

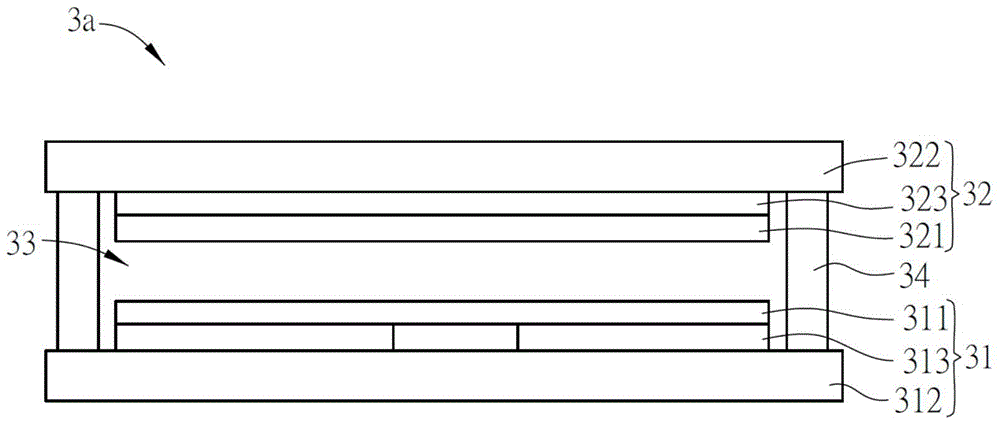

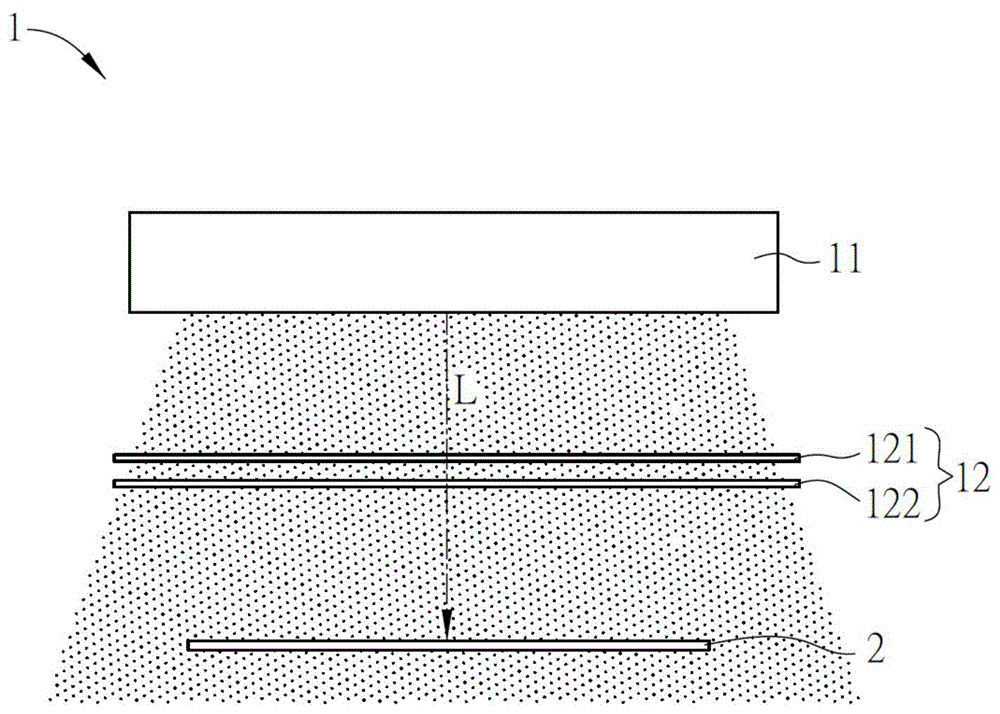

[0051] The exposure system and exposure process according to the preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

[0052] The exposure system can perform an exposure process on an assembly liquid crystal cell, so that the photoreactive monomers in the liquid crystal in the assembled liquid crystal panel can be polymerized into a polymer alignment layer that can control the liquid crystal alignment. The so-called "assembled liquid crystal panel" here refers to a panel that has completed the filling and assembly of the upper and lower substrates and the liquid crystal layer, but has not been cut to become a single display panel product. Wherein, an assembled liquid crystal panel may contain one display panel (including a set of upper and lower substrates and a liquid crystal layer), or multiple sets of display panels (including multiple sets of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com