Intelligent card module

A smart card and functional pad technology, applied in the field of smart card modules, can solve the problems of high production cost and storage cost of smart card modules, discharge of acid pollutants and waste water, inability to solder pads, etc., and achieve high environmental protection effect and low operating cost. The effect of low, continuous performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

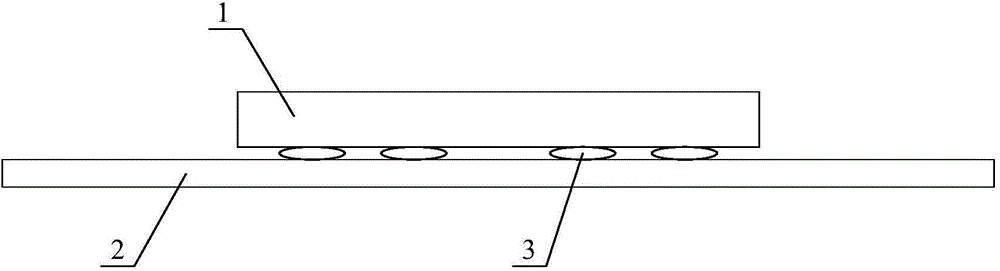

Embodiment 1

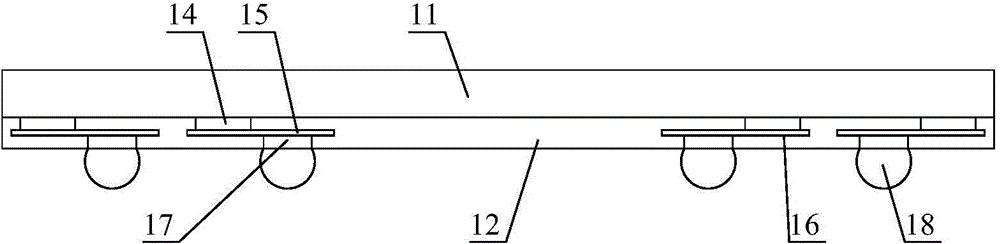

[0052] like image 3 As shown, a plurality of functional pads 14 of the chip 11 and a plurality of functional pads 15 of the carrier 12 are welded together in one-to-one correspondence, so that a plurality of functional pads 14 of the chip 11 and the carrier The multiple functional pads 15 of 12 are connected in one-to-one correspondence. The plurality of functional pads 15 of the carrier 12 are respectively provided with bump solder balls 18, and the plurality of functional solder pads 15 of the carrier 12 are welded with the carrier tape functional pads through the bump solder balls 18 respectively. together. Since the function of the bump solder balls 18 is to allow the plurality of functional pads 15 of the carrier 12 of the chip packaging module 1 to realize electrical conduction with the functional pads of the carrier tape 2, so the The material of the bump solder ball 18 should be a metal soldering material with better electrical conductivity; further, the material of...

Embodiment 2

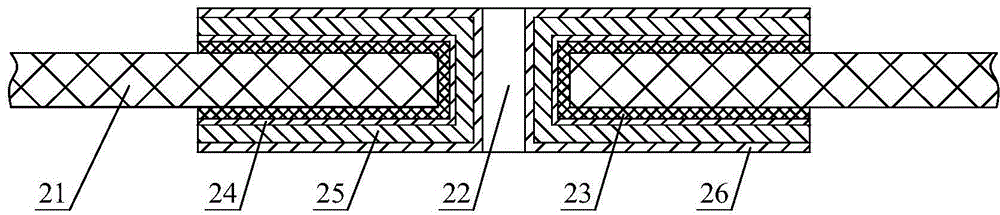

[0058] like Figure 4 As shown, the chip 11 is fixed on the carrier 12 by an adhesive 13 , and the multiple functional pads 14 of the chip 11 are respectively connected to the corresponding functional pads 15 of the carrier 12 through wires.

[0059] Then the manufacturing method of the smart card module of embodiment two is as follows:

[0060] The making of carrier tape 2: same as embodiment one.

[0061] The making of chip packaging module 1: as Figure 4 As shown, the chip 11 is fixed on the carrier 12 with an adhesive 13; then the functional pads 14 of the chip 11 and the corresponding functional pads 15 of the carrier 12 are wire-bonded to make the chip A plurality of functional pads 14 of 11 are respectively connected to the corresponding functional pads 15 of the carrier 12 through wires; afterward, in order to make the chip 11 achieve high reliability in any use environment, after wire bonding The chip 11 and the carrier 12 are subjected to injection molding packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com