Electrochemical preparation method of 3.5 valence vanadium electrolyte

An electrochemical and electrolyte technology, applied in the field of electrochemical preparation of 3.5-valent vanadium electrolyte, can solve the problems of complex preparation process, high price, unsuitable for large-scale production of electrolyte, etc., to reduce cross-contamination and oxidation resistance. requirements, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

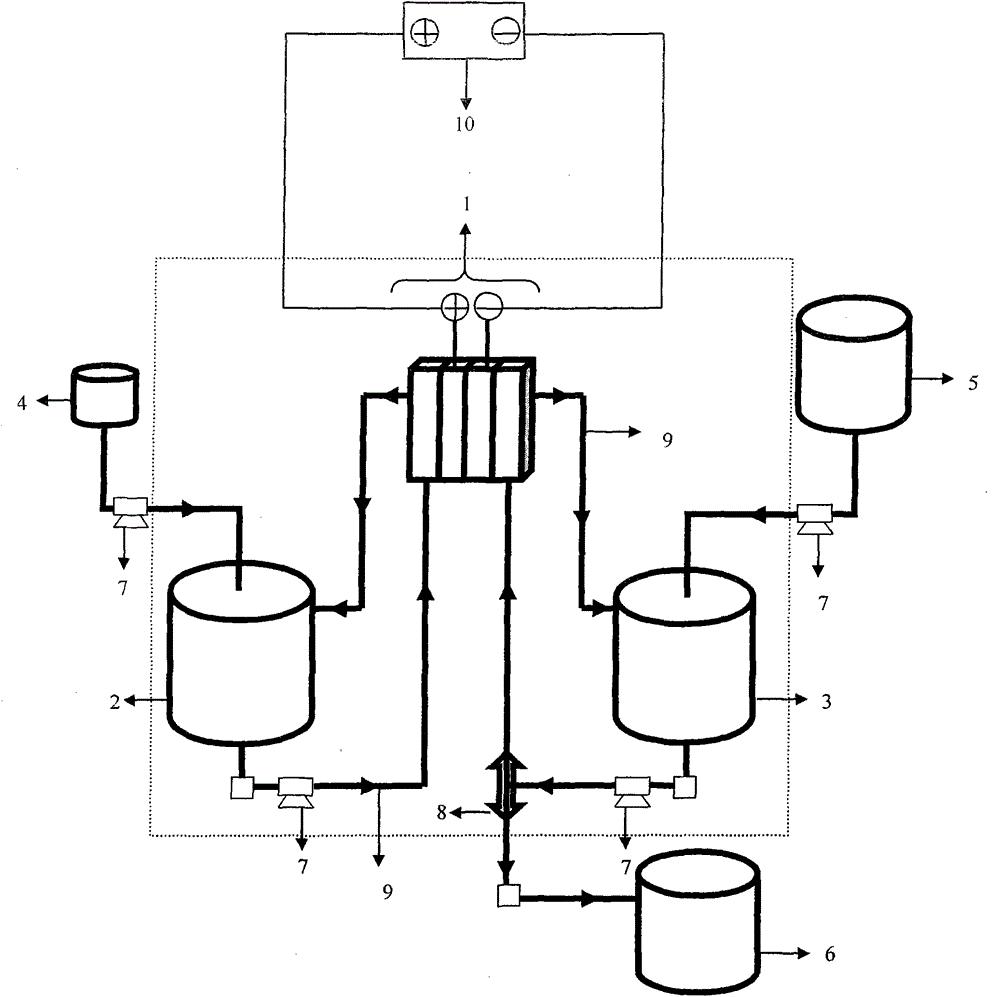

Image

Examples

example 1

[0020] Will 11 liters 1.6MVOSO 4 +3MH 2 SO 4 The solution is injected into the positive electrode tank, and 20 liters of 1.6MVOSO 4 +3MH 2 SO 4 The solution is injected into the negative electrode tank, and the electrode area of the electrolytic cell is 0.9m 2 , use nafionl15 membrane to separate the electrolytic cell, use constant current electrolysis method, carry out constant current electrolysis at a current density of 180 amps, control the cell voltage at 1.8V, otherwise reduce the electrolysis current, after the electrolysis power reaches 428.8Ah, stop electrolysis, set 3.5 The negative vanadium solution of the price is discharged, and 20 liters of 1.6MVOSO are re-injected 4 +3MH 2 SO 4 solution, at the same time, add water and hydrazine 4.8M to the positive electrode solution, after the reaction is complete, repeat the last electrolysis.

example 2

[0022] Will 11 L 2.0MVOSO 4 +3MH 2 SO 4 solution into the positive tank, 20 liters of 2.0MVOSO 4 +3MH 2 SO 4 The solution is injected into the negative electrode tank, and the electrode area of the electrolytic cell is 0.9m 2 , use nafionl15 membrane to separate the electrolytic cell, use the constant current electrolysis method, carry out constant current electrolysis at a current density of 180 amps, control the cell voltage at 1.8V, otherwise reduce the electrolysis current, after the electrolysis power reaches 536Ah, stop the electrolysis and change the valence of 3.5 The negative vanadium solution is discharged, and 20 liters of 2.0MVOSO are re-injected 4 +3MH 2 SO 4 solution, at the same time, add water and hydrazine 6.0M to the positive electrode solution, after the reaction is complete, repeat the last electrolysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com