Hollow heating seedling cultivating box and application thereof

A seedling box and hollow technology is applied in the field of heating hollow seedling boxes, which can solve the problems of difficult rooting of cuttings, low seedling rate and not being widely used, and achieve the effects of avoiding a large amount of loss, high seedling rate and reducing seedling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

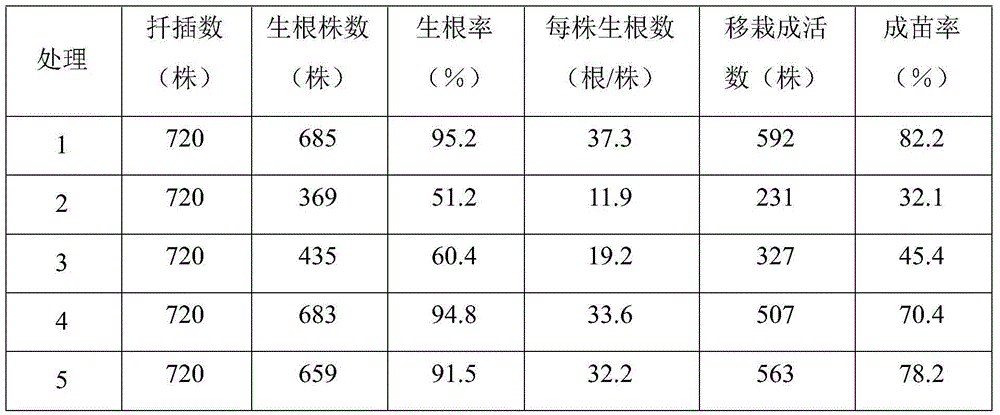

[0021] (1) Processing method 1

[0022] 1. The preparation of the nursery site: the required nursery site for this method is in a plastic greenhouse. The plastic greenhouse has the characteristics of heat preservation, rain and snow protection, which is beneficial to reduce power consumption, and is easy to operate and manage.

[0023] 2 Production of seedling raising frame: welded with triangle iron to form a frame of 2.2m×1.2m×1.6m. 3-layer structure, the height of the feet is 20cm, the distance between each layer is 70cm, and a seedling box is placed on each layer.

[0024] 3 Heated seedling raising box production: the seedling raising box is made of color steel composite board with a thickness of 5.0cm, and the outer diameter, length, width and height of the box body are 210cm, 110cm and 30cm respectively. Connect two geothermal wires with a specification of 33 ohms / m in parallel at an interval of 5 cm, spread the bottom of the box along the longitudinal direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com