Preparation method for natural high-Vc ultrafine persimmon leaf tea powder

A production method and persimmon leaf tea technology are applied in the production field of natural high-Vc ultra-fine persimmon leaf tea powder, which can solve the problems of reducing the content of inclusions, not being a natural product, affecting the flavor of persimmon leaf tea, etc., and achieving antioxidant capacity. The effect of improving, enriching the variety, and improving the immunity of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of preparation method of natural high Vc ultrafine persimmon leaf tea powder, its steps are as follows:

[0019] (1) The persimmon varieties selected are Matsumoto Zaosheng or Late Gosho or Early Autumn or Xiangxi sweet persimmons. The picking time is May 10 or 12 or 14 or 16 or 18 or 20 in the Gregorian calendar. The standard is tender green leaves and leaves free of diseases and insect pests. fresh leaves;

[0020] (2) Fix the fresh leaves in a frying pan, the leaf temperature is 60 or 62 or 64 or 65°C, and the time is 60 or 70 or 80 or 90s to obtain the fixed leaves;

[0021] (3) Freezing (at about -110°C) and drying the solid sample leaves, the moisture content of the dried leaves is ≤5%, and the dried leaves are obtained;

[0022] (4) The dried leaves are ultrafinely pulverized in a turbine pulverizer, a vibrating mill pulverizer, a flat jet pulverizer or a composite force field superfine pulverizer, and then passed through a 400-mesh sieve to prepare a 38-...

Embodiment 2

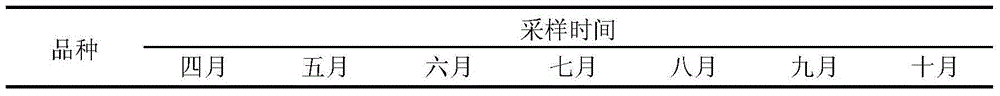

[0024] Embodiment 2: Analysis of the Vc content of persimmon leaves in different varieties and harvest periods:

[0025] Pick fresh persimmon leaves from April in the Gregorian calendar. The standard is tender green leaves and leaves free of diseases and insect pests. The quality of the fresh leaves is fixed in a 6CST-50 frying pan after being properly spread indoors, the leaf temperature is about 65°C, and the time is about 60s. The solid sample leaves are dried in a freeze dryer for 24-48 hours, and the water content of the dried leaves is controlled to be ≤5%. Select 16 persimmon varieties and sample them once a month from April to October in the Gregorian calendar. The dates are April 15, May 11, June 10, July 17, August 16, and September 17. , On October 31, the Vc content was analyzed by HPLC. The results (Table 1) showed that the Vc content in persimmon leaves was relatively high, and there were large differences among different varieties, and the content was the high...

Embodiment 3

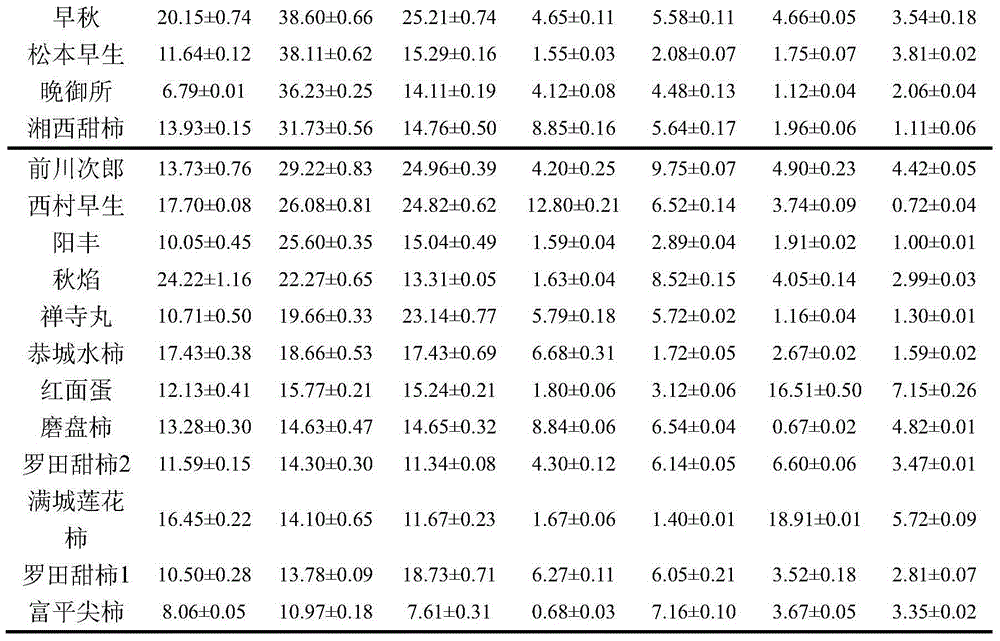

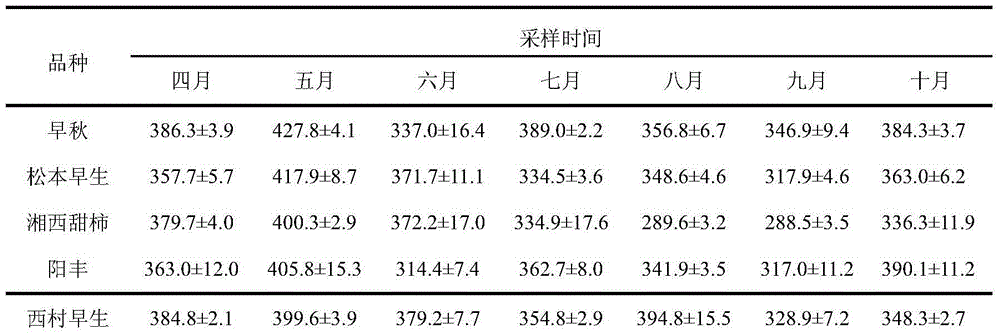

[0029] Embodiment 3: Analysis of the content of persimmon leaf water extract in different varieties and harvest periods:

[0030] Pick fresh persimmon leaves from April in the Gregorian calendar. The standard is tender green leaves and leaves free of diseases and insect pests. The quality of the fresh leaves is fixed in a 6CST-50 frying pan after being properly spread indoors, the leaf temperature is about 65°C, and the time is about 60s. The solid sample leaves are dried in a freeze dryer for 24-48 hours, and the water content of the dried leaves is controlled to be ≤5%. Select 16 persimmon varieties and sample them once a month from April to October in the Gregorian calendar. The dates are April 15, May 11, June 10, July 17, August 16, and September 17. , On October 31, the content of its water extract was analyzed. The results (Table 2) show that the content of persimmon leaf tea extracts fluctuates between 26.84%-42.78%, the lowest value of most varieties occurs in June ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com