Preparation method of ultramicro spirulina powder as well as preparation and application thereof

A kind of spirulina powder and ultrafine technology, applied in the field of traditional Chinese medicine, can solve the problems of unreasonable formula, cumbersome production process, and many auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of embodiment 1 ultrafine spirulina powder (average particle diameter is 200~800nm)

[0049] Get common spirulina (the spirulina that Sanya Haiwang Marine Biotechnology Co., Ltd. produces and provides, dry, pulverize, cross 100 mesh sieves), be processed into superfine spirulina powder (200~800nm), and its method comprises the following steps:

[0050] ① Coarse powder the dried spirulina powder (moisture content below 5%) to below 100 mesh.

[0051] ② The crushed spirulina powder is ultrafinely pulverized by a high-energy nano-impact mill, and the grinding medium in the high-energy nano-impact mill tank is continuously impacted and ground for 6-10 hours, so that the average particle size of the spirulina powder reaches 200-800nm .

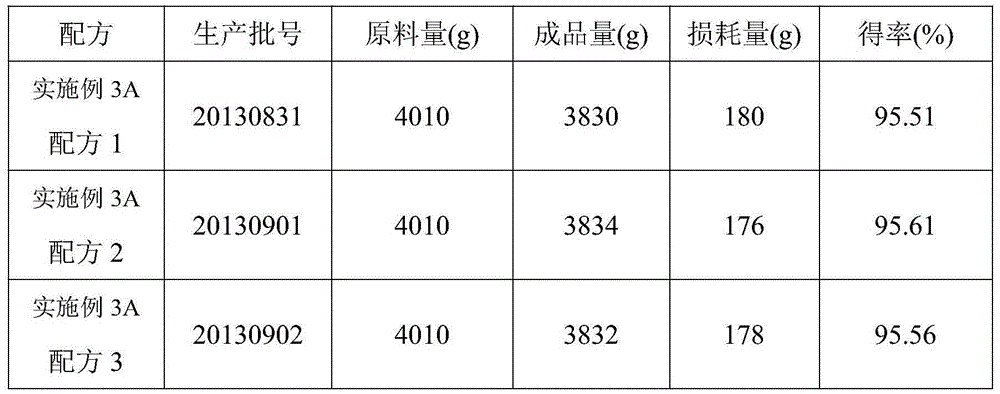

[0052] See Table 1 for detailed production data

[0053] Table 1 Production dynamic data table of ultrafine spirulina powder

[0054] the batch

[0055] 3

[0056] (Remarks: These 3 batches have ...

Embodiment 2

[0057] The preparation method of embodiment 2 ultrafine spirulina powder (average particle diameter is 200~800nm)

[0058] ① Freeze-thaw extraction: take common spirulina (spirulina produced by Sanya Haiwang Marine Biotechnology Co., Ltd., dry, crush, and pass through a 100-mesh sieve) and soak it in distilled water (algae: water ratio 1:1, W / W) at room temperature Put it overnight, put it in the refrigerator to cool to -15°C the next day, then put it in a constant temperature and humidity box at 40°C to thaw quickly, repeat freezing and thawing 3 times, centrifuge separately to get the supernatant, and keep the separated algae residue for later use , combined, and freeze-dried (the main drying stage controls the temperature at -5°C, the vacuum chamber pressure is 15Pa, and the drying time is 380min) to obtain the water extract;

[0059] ②The algal residue is dried to obtain the algal residue product.

[0060] ③Uniformly mix the water extract and the algae residue product to ...

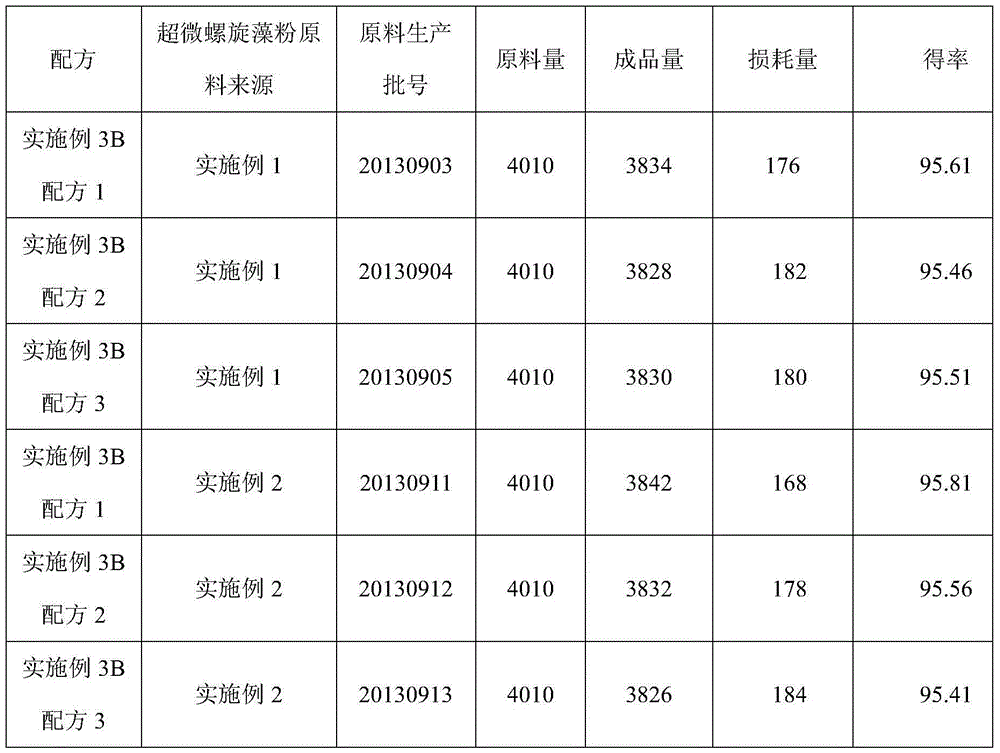

Embodiment 3

[0070] A: Preparation process 1 of spirulina sheet (the raw material is common spirulina powder)

[0071] 1) Formula 1: ordinary spirulina powder: 3930g; hypromellose: 16g; magnesium stearate: 64g.

[0072] ① Accurately weigh 3930g of ordinary spirulina powder (the spirulina produced by Sanya Haiwang Marine Biotechnology Co., Ltd., dried, crushed, and passed through a 100-mesh sieve).

[0073] ② Weigh 16g of hypromellose and purified water and mix them uniformly in proportion to prepare a 5.0% hypromellose solution as a binder;

[0074] ③Add the hypromellose solution into the spirulina powder, and pass through a 20-mesh sieve to obtain wet particles.

[0075] ④ The wet granules are dried at 50-60°C until the water content of the granules is less than 3.0%, to obtain dry granules.

[0076] ⑤Add 64g of magnesium stearate and mix for 20 minutes to obtain total blend granules.

[0077] ⑥Place the blended granules in a tablet press, and press the tablet with a tablet weight of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com