Method for purifying waste gases during medical waste incineration

A technology for medical waste and incineration flue gas, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of poor dust removal effect, fragmentation, filter bag blockage, etc., to improve gas distribution effect and efficient removal. , the effect of improving the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

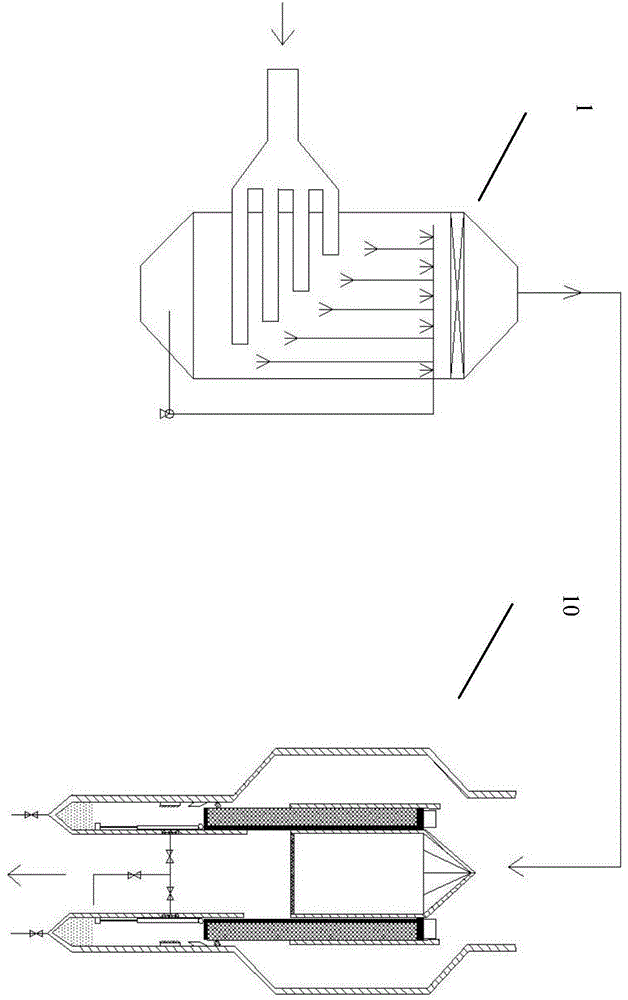

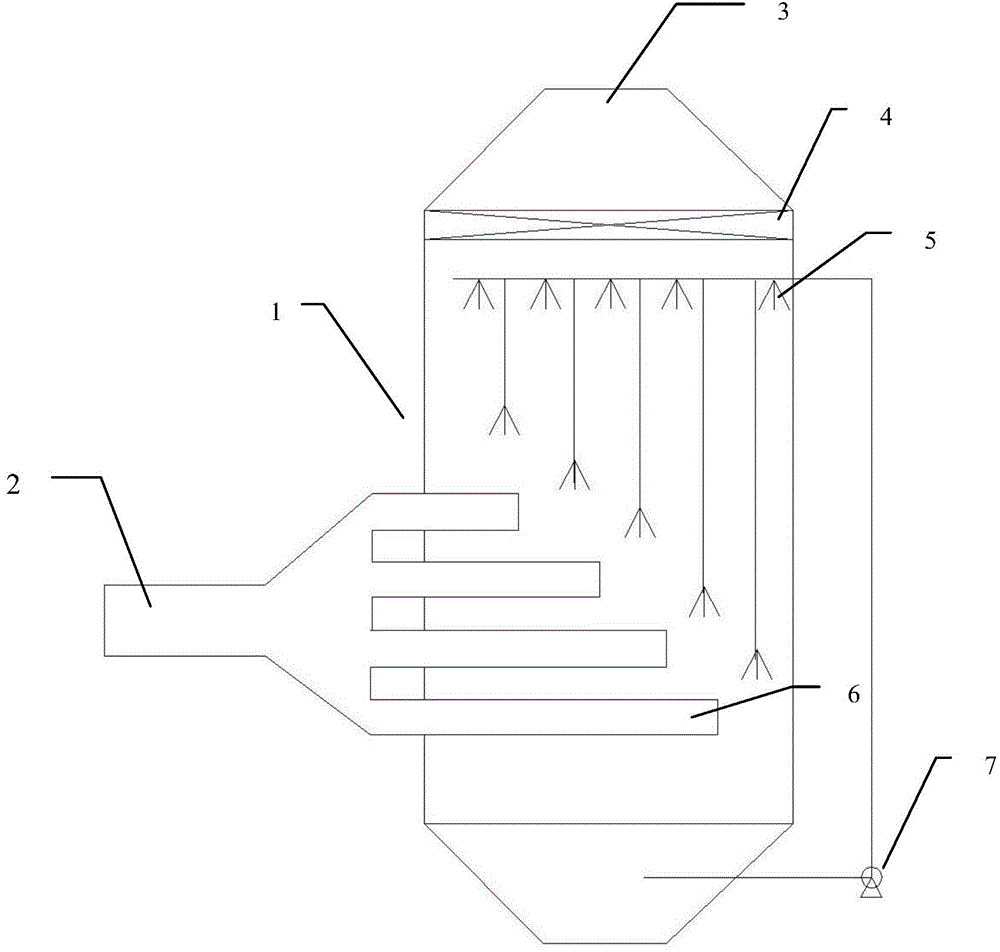

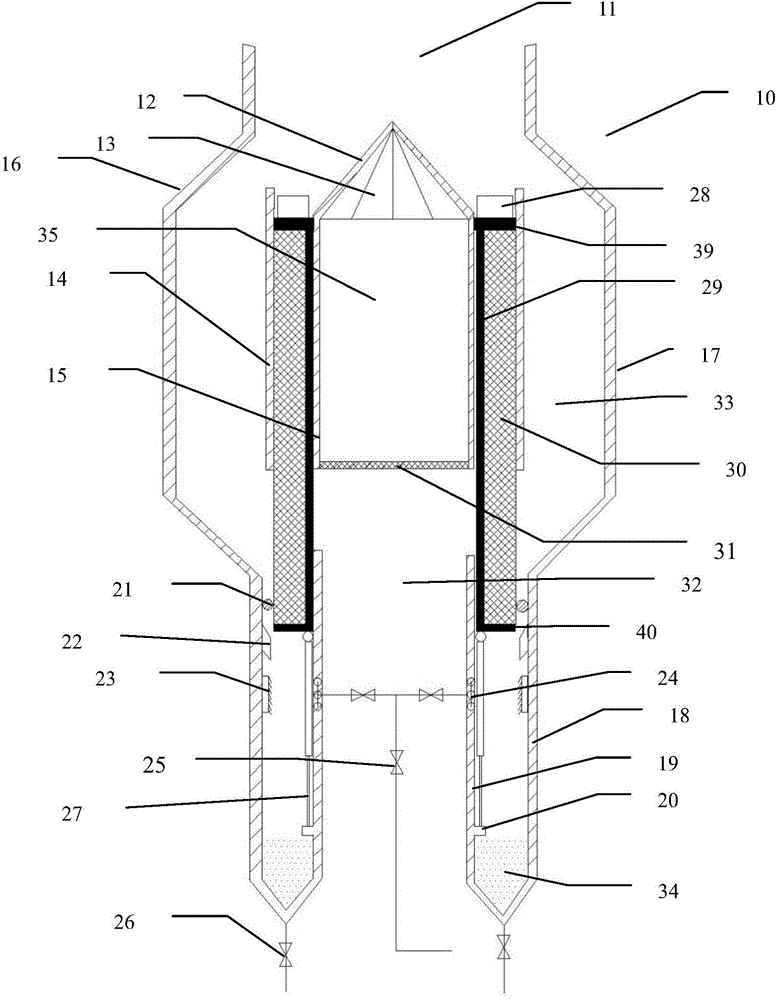

[0034] Such as figure 1 , figure 2 As shown, the temperature of medical waste incineration flue gas is about 400°C-600°C, and the flue gas contains HCl, SOx, solid particles, heavy metals, etc. The flue gas first enters the absorption tower 1, and after the gas inlet 2 of the absorption tower enters the absorption tower 1, it becomes four branch inlets 6. The branch inlets 6 are evenly distributed in the absorption tower along the oblique line from top to bottom, and the uppermost branch inlet is far from the gas Inlet 2 is the closest, and the lowermost branch inlet is farthest from gas inlet 2. The 4 branch inlets can basically realize the uniform distribution of gas. A corresponding sprayer 5 is provided on the upper part of each branch entrance, and the sprayer 5 is 1m away from the branch entrance. Since the gas inlet is divided into several branch inlets, the reaction efficiency can be improved by setting corresponding sprayers at each branch inlet, and the distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com