Device and method for treating ammonium nitrate wastewater by biological method

A technology of ammonium nitrate and biological method, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and fast loss, and achieve simple control and simple operation Convenience and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

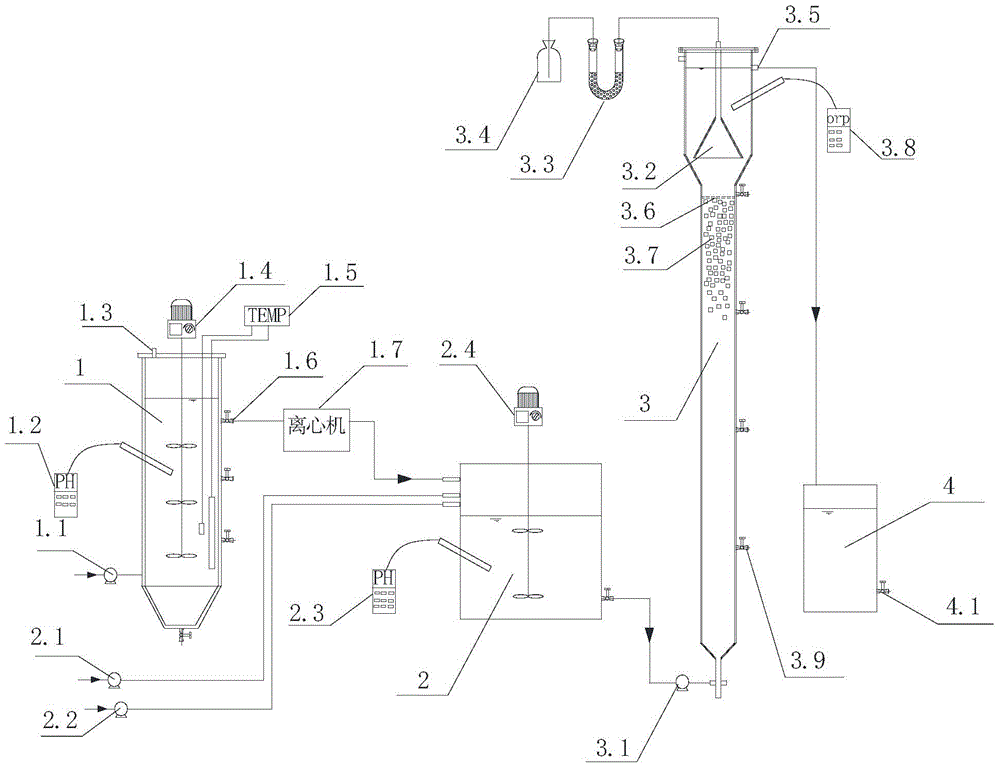

[0039] The present invention will be further described in conjunction with accompanying drawing and example: as Figure 1 As shown, the present invention includes an anaerobic fermentation reactor SBR1, a mixing tank 2, an upflow anaerobic sludge bed reactor 3 and a drainage tank 4 connected in sequence. Among them, the effective volume of the anaerobic fermentation reactor SBR is 5L, which is a cylindrical plexiglass column; the effective volume of the mixing tank 2 is 50L, made of plexiglass; the effective volume of the upflow anaerobic sludge bed reactor UAFB3 is 3.2L , wherein the reaction zone is 2.28L, the precipitation zone is 0.92L, and the reactor is made of plexiglass.

[0040] The sludge inlet pump (1.1) is connected to the anaerobic fermentation reactor SBR (1), and the anaerobic fermentation reactor (1) is connected to the centrifuge (1.7) through the first sludge discharge valve (1.6), and the obtained supernatant enters the mixing tank In (2), the remaining slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com