Sewage treatment device and method by combining bio-ferric process and anaerobic MBR method

A sewage treatment method and bio-iron technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as membrane fouling, strengthen biological effects, and facilitate management and operation. , The device has the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

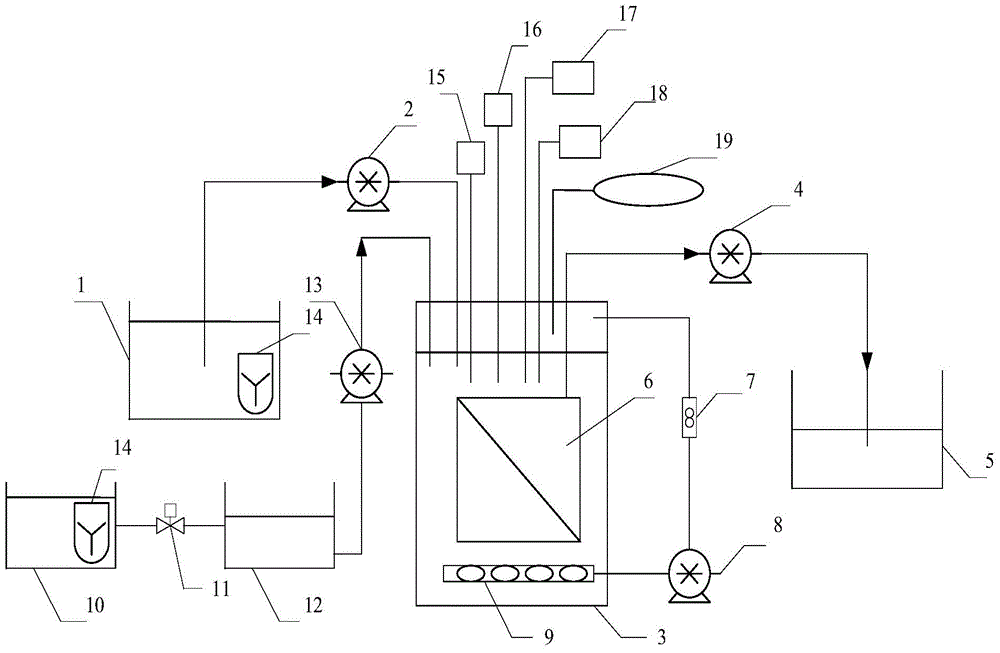

[0034] Such as figure 1 As shown, a sewage treatment device combining biological iron method and anaerobic MBR method is characterized in that: comprising: the water outlet of the water inlet pool 1 is connected to the water inlet of the water inlet pump 2, and the water outlet of the water inlet pump 2 is connected to the anaerobic The water inlet of oxygen membrane bioreactor 3 links to each other, and the top of described anaerobic membrane bioreactor 3 is also respectively connected with the water inlet of biological iron adding device, gas collection device 19, the air inlet of gas flowmeter 7, temperature sensor 16 , redox potential sensor 17, pH sensor 18 are connected with liquid level controller 15, the water outlet of described anaerobic membrane bioreactor 3 is connected with the water inlet of suction pump 4, and the water outlet of described suction pump 4 is connected with The water inlet of the effluent pool 5 is connected; the biological iron addition device co...

Embodiment 2

[0057] Such as figure 1 As shown, a sewage treatment device combining biological iron method and anaerobic MBR method is characterized in that: comprising: the water outlet of the water inlet pool 1 is connected to the water inlet of the water inlet pump 2, and the water outlet of the water inlet pump 2 is connected to the anaerobic The water inlet of oxygen membrane bioreactor 3 links to each other, and the top of described anaerobic membrane bioreactor 3 is also respectively connected with the water inlet of biological iron adding device, gas collection device 19, the air inlet of gas flowmeter 7, temperature sensor 16 , redox potential sensor 17, pH sensor 18 are connected with liquid level controller 15, the water outlet of described anaerobic membrane bioreactor 3 is connected with the water inlet of suction pump 4, and the water outlet of described suction pump 4 is connected with The water inlet of the effluent pool 5 is connected; the biological iron addition device co...

Embodiment 3

[0072] Such as figure 1 As shown, a sewage treatment device and method combining biological iron method and anaerobic MBR method, the iron content of the prepared biological iron flocculant is 5% of the sludge quality, and the temperature in the anaerobic membrane bioreactor 3 is 29 ℃, oxidation-reduction potential of -200mV, pH value of 7.0, sludge concentration of 5g / L, aeration and scour rate of membrane surface aeration device 9 of 8L / m 2 h, the time for water purification in the anaerobic membrane bioreactor 3 is 6 h each time; the remaining contents are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com