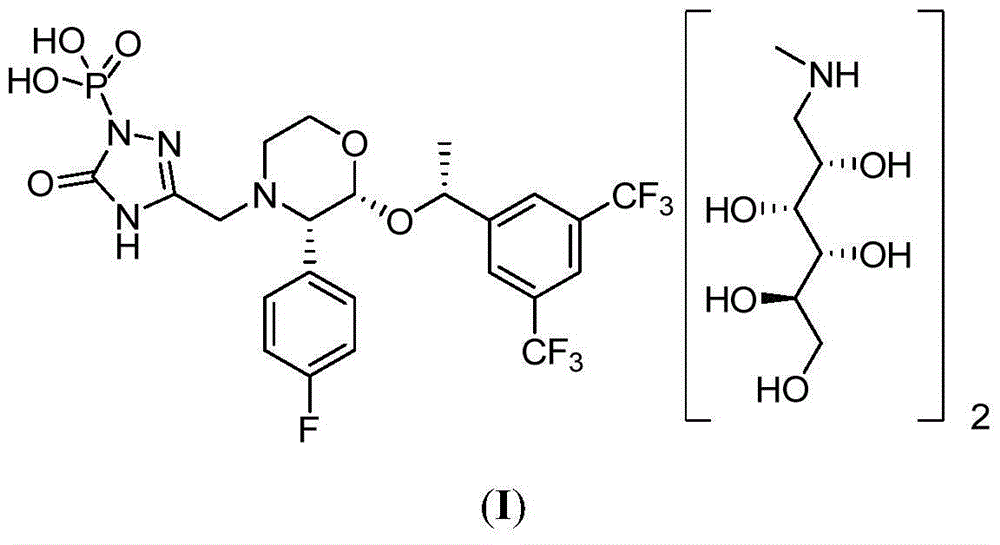

Refining method of fosaprepitant dimeglumine

A technology of fosaprepitant dimeglumine and its refining method, which is applied in the field of refining fosaprepitant dimeglumine bulk drug, and can solve the problems such as difficult drying of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

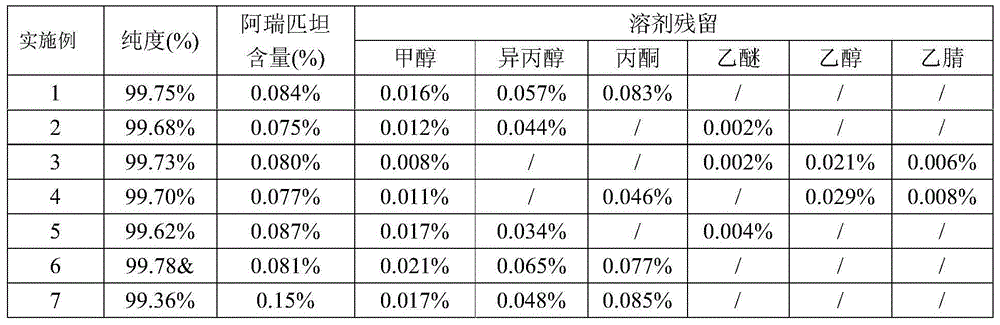

Examples

Embodiment 1

[0020] Dissolve 40g of fosaprepitant dimeglumine in 160ml of methanol solution dropwise into 500ml of isopropanol solvent that is being stirred, control the temperature below 20°C, and precipitate a solid, continue stirring for 0.5 to 1 hour after dropping, filter, The filter cake was washed with 50ml of acetone, the filter cake was beaten with 500ml of acetone, stirred for half an hour, filtered, the solid was collected, and vacuum-dried for 8 hours to obtain 37.4g of fosaprepitant dimeglumine with a yield of 93.5%.

Embodiment 2

[0022] Dissolve 25g of fosaprepitant dimeglumine in 100ml of methanol solution into 400ml of isopropanol solvent which is being stirred, and control the temperature at 20°C to precipitate a solid. Continue stirring for 0.5 to 1 hour after dropping, and filter. The filter cake was washed with 20 ml of ether, and the filter cake was slurried with 150 ml of ether, stirred for half an hour, filtered, and the solid was collected and vacuum-dried for 8 hours to obtain 23.8 g of fosaprepitant dimeglumine, with a yield of 95.2%.

Embodiment 3

[0024] Dissolve 25g of fosaprepitant dimeglumine in 100ml of methanol into a stirred 400ml of ethanol / acetonitrile (1:1) solvent, control the temperature at about 20°C, and precipitate a solid, continue stirring for 0.5~ 1 hour, filtered, the filter cake was washed with 20ml of ether, the filter cake was beaten with 150ml of ether, stirred for half an hour, filtered, the solid was collected, and vacuum-dried for 8 hours to obtain 22.3g of fosaprepitant dimeglumine, with a yield of 89.2% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com