A slurry for antistatic devices

A technology of electrical devices and pastes, which is applied in the field of pastes for antistatic devices, can solve problems such as the leakage current of laminated varistors that cannot meet the needs, improve reliability and stability, improve electrostatic shock resistance, Effect of Reducing Leakage Current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

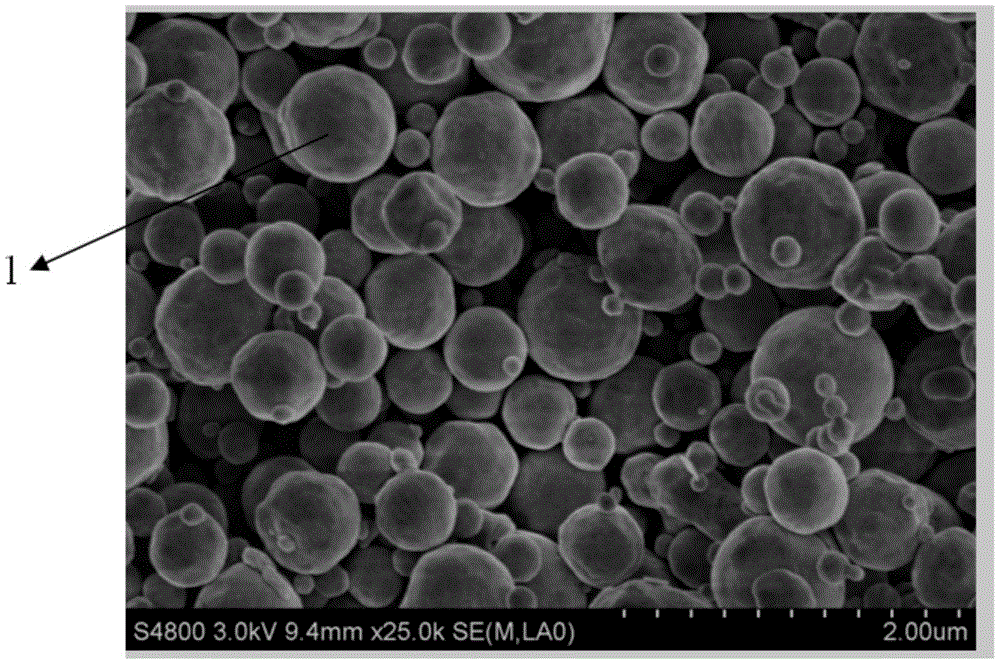

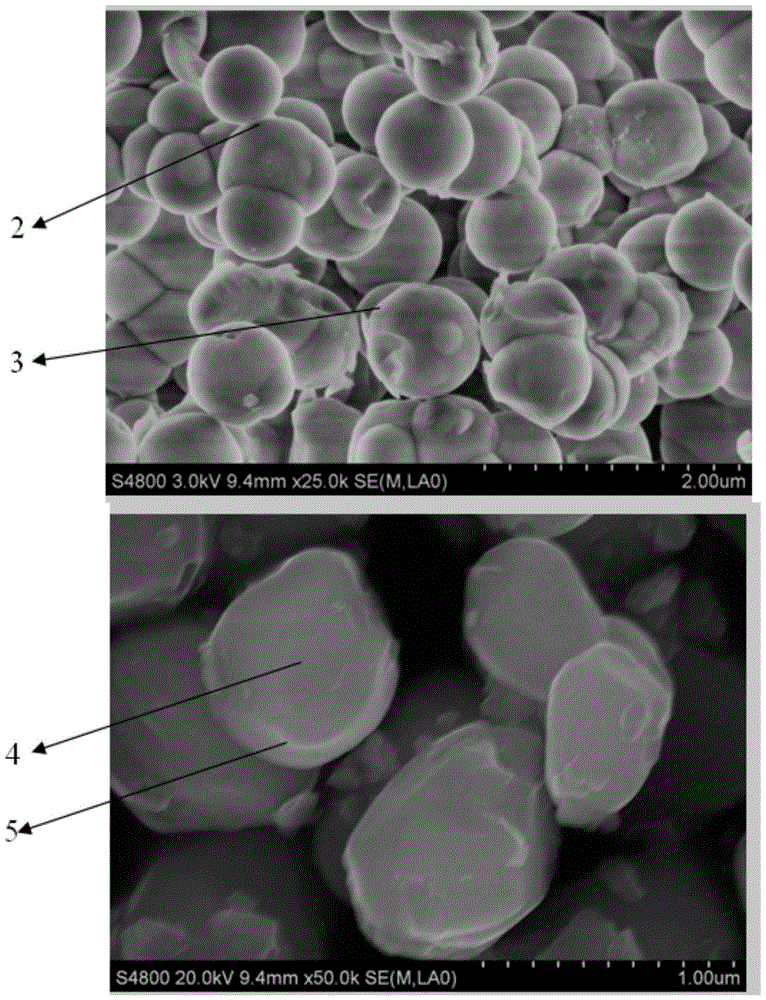

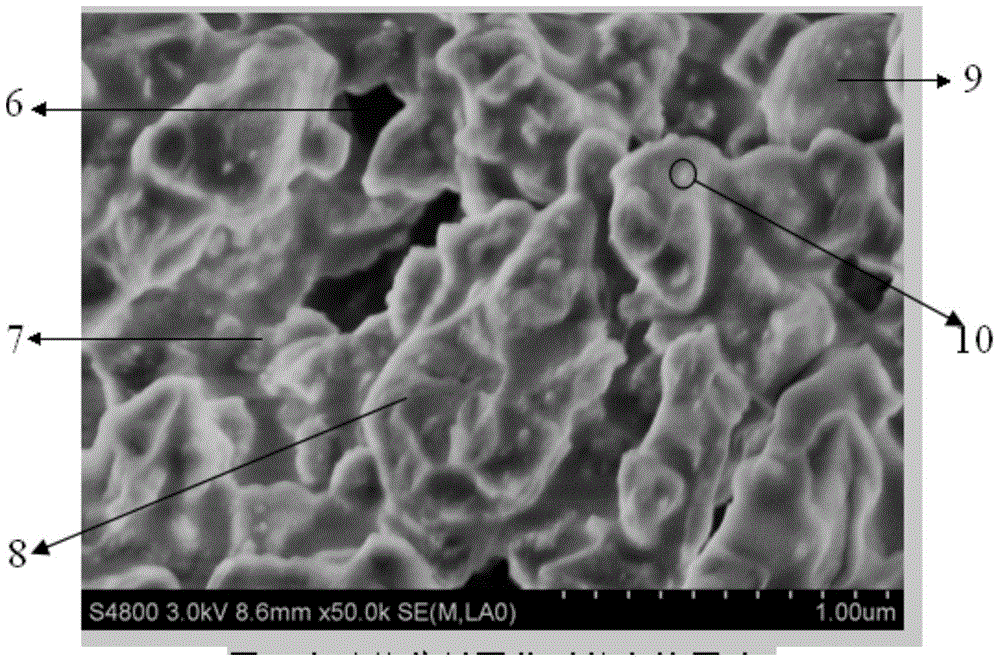

Image

Examples

Embodiment Construction

[0049] Below in conjunction with embodiment 1~5, the present invention will be further described:

[0050] Step 1. Prepare glass powder. The formula of the glass powder raw material is mainly composed of the following materials in mass percentage as shown in the table below:

[0051] serial number SiO 2

PbO B 2 o 3

al 2 o 3

Cr 2 o 3

Li 2 o

CaO ZnO K 2 o

La 2 o 3

Example 1 20.00% 51.00% 15.00% 3.00% 1.00% 2.00% 2.00% 5.00% 0.50% 0.50% Example 2 25.00% 48.00% 12.50% 5.00% 1.50% 0.50% 2.00% 5.00% 0.50% 0.00% Example 3 30.00% 40.00% 16.00% 4.00% 2.00% 1.00% 2.00% 4.50% 0.50% 0.00% Example 4 35.00% 35.00% 20.00% 3.00% 1.00% 1.00% 1.00% 3.50% 0.50% 0.00% Example 5 40.00% 30.00% 22.50% 3.00% 3.00% 0.00% 0.00% 1.00% 0.50% 0.00%

[0052] The sum of the mass percentages in the above table is 100%. The addition of trace elements can adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com