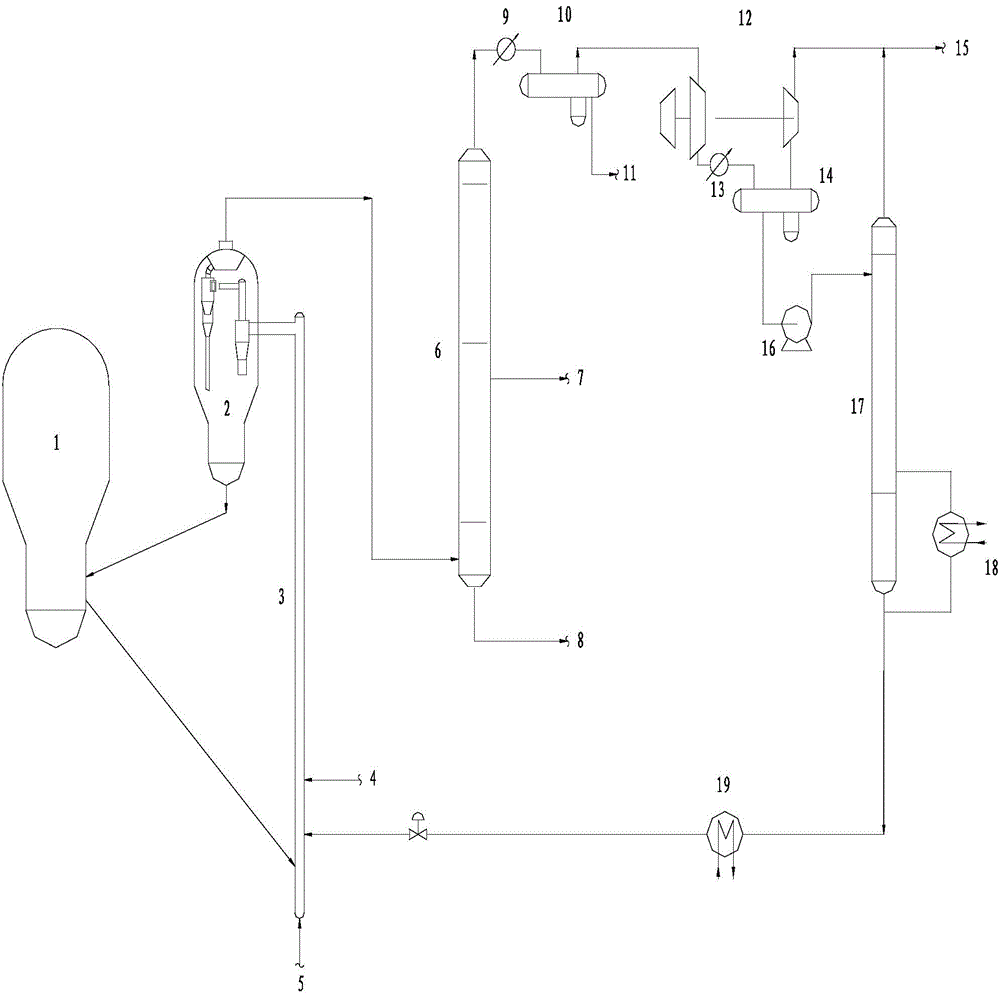

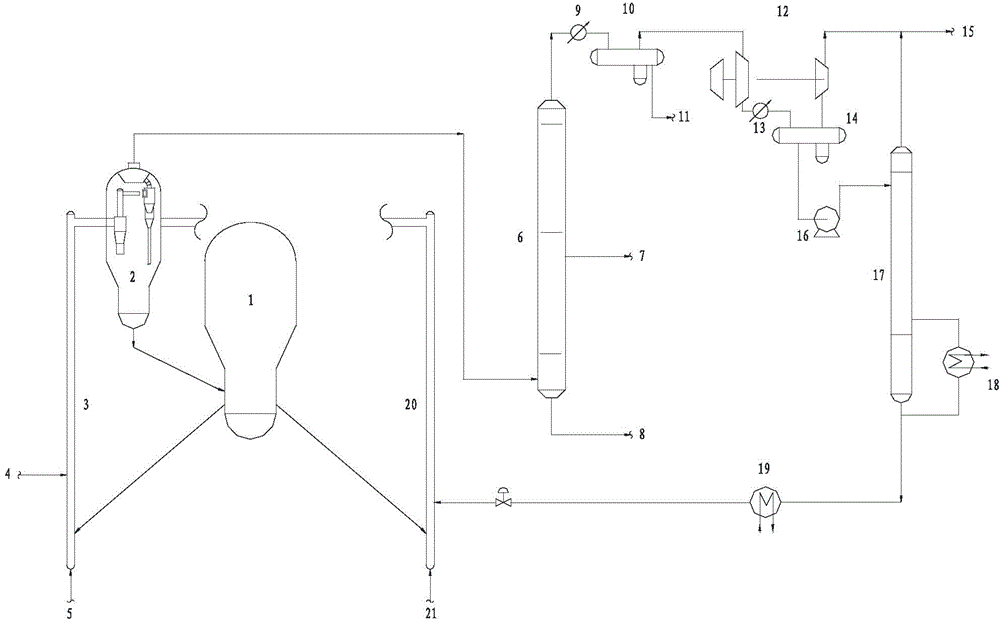

Improved catalytic cracking technology method

A process method and catalytic cracking technology, which is applied in the fields of refining and cracking process treatment, petroleum industry, hydrocarbon oil treatment products, etc., which can solve the problems of high energy consumption of the device and restrictions on popularization and application, and achieve the reduction of impurity content , low comprehensive energy consumption, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] For verifying effect of the present invention, adopt raw material oil shown in table 1, process condition shown in table 2 is tested, and test result is listed in table 3. In this embodiment, the first riser is used to feed raw oil, and the second riser is used to feed back refined condensate oil.

[0030] Table 1 Example raw material properties

[0031] Raw oil

[0032] Table 2 Example operating conditions

[0033] parameters

[0034] Table 3 Application effect of the embodiment

[0035] product

[0036] As can be seen from the results in Table 3, the technology of the present invention can be used to obtain ideal product distribution, especially the propylene yield can reach 18wt%, the gasoline olefin content ~ 33v%, has good product quality, and the comprehensive energy consumption is lower than 80% Kilogram standard oil / ton raw material. The inventive technology has obvious advantages in increasing the yield of low-carbon olefins (es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com