Unhusked rice drying device under effect of combination of ultrasonic waves and hot air

A drying equipment and ultrasonic technology, applied in the field of drying equipment and grain machinery, can solve the problems of low economic benefit, low quality of rice and high energy consumption, and achieve the effect of reducing energy consumption, rationally utilizing energy and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

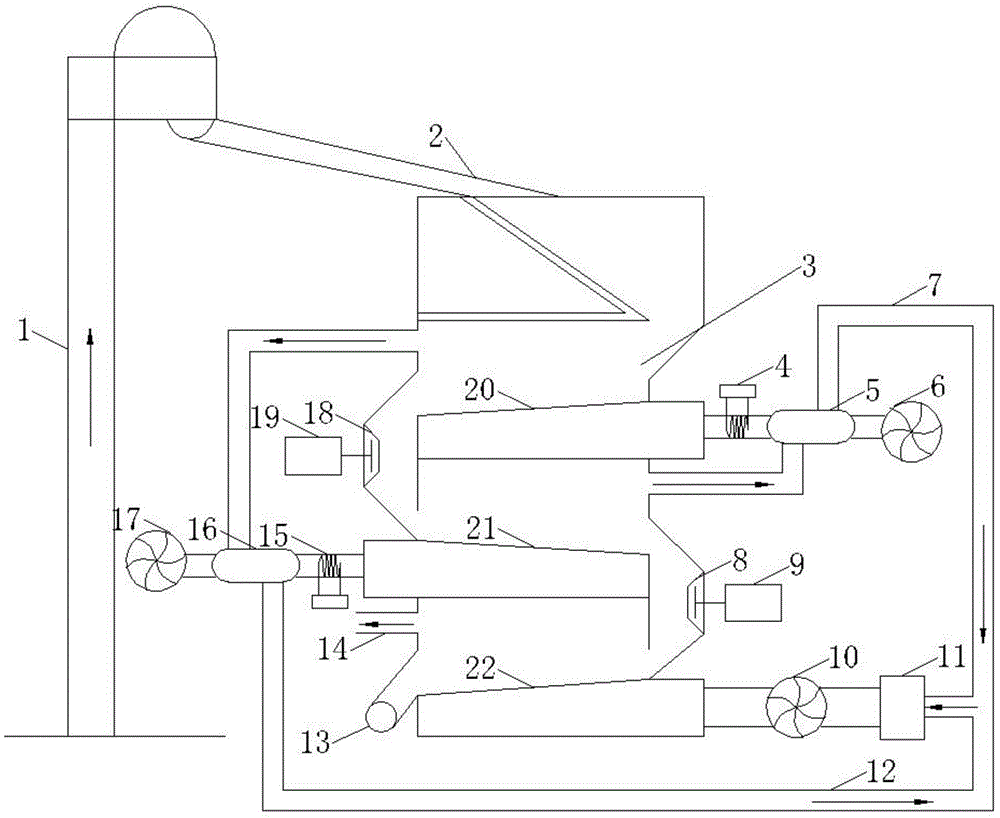

[0012] The drying equipment of the present invention transports the paddy into the drying chamber 3 through the feed channel 2 through the hoist 1 . Paddy is transported on the gas distribution orifice 20, and the lower temperature hot blast provided by blower 6 and electric heater 4 carries out fluidized drying. During the falling process (as shown in the figure) on the left side of the drying chamber 3, the paddy is slowed down under the action of the ultrasonic wave emitted by the ultrasonic generating device 19. Wire cover 18 plays a protective role. The second layer of drying repeats the drying-ultrasonic slow recovery process, but the hot air temperature provided by the blower 17 and the electric heater 15 is higher than the first layer of drying hot air temperature. At the same time, the hot air after the first layer is subjected to heat and humidity exchange passes through the high-efficiency gas heat exchanger 16 to preheat the air in the second layer as the drying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com