Efficient dispersion mixer

A mixer and dispersing technology, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problems of small viscosity range, low working efficiency, long mixing time, etc., and achieve large stirring coverage and reasonable structure design. , The effect of strong stirring and dispersing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

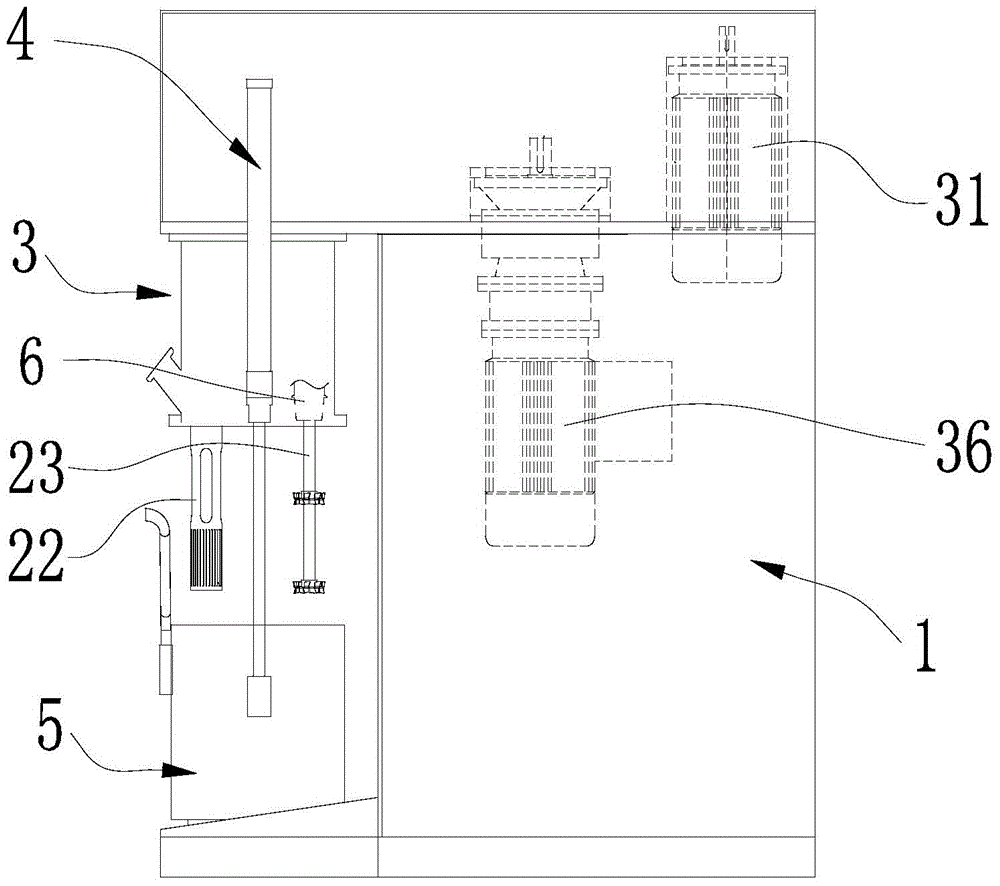

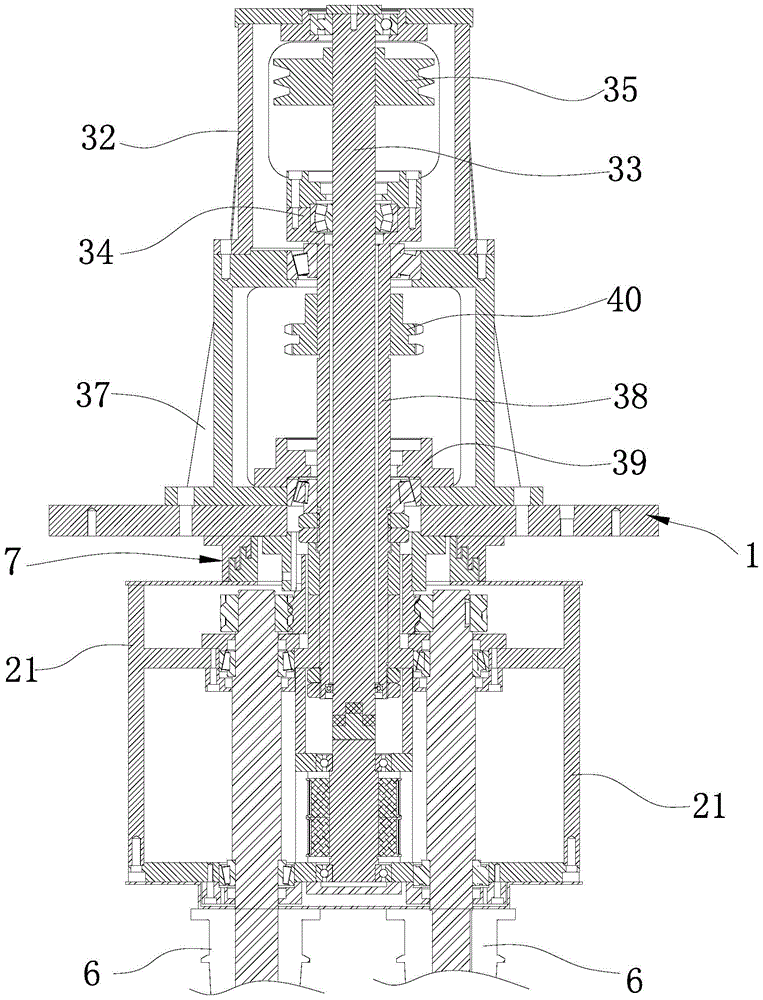

[0024] see Figure 1 to Figure 7 , a kind of high-efficiency dispersing mixer provided by the present embodiment includes a machine base 1, which also includes an efficient dispersing and mixing mechanism 2, a driving mechanism 3 and a lifting device 4 for controlling the up and down movement of the mixing barrel body 5, The driving mechanism 3 is arranged on one side of the machine base 1, the high-efficiency dispersing and mixing mechanism 2 is arranged on the top of the other side of the machine base 1, and is connected with the driving mechanism 3, and the lifting device 4 is arranged on The side of the high-efficiency dispersing and mixing mechanism 2 can smoothly lift the mixing barrel 5 to the predetermined position required by the high-efficiency dispersing and mixing mechanism 2 .

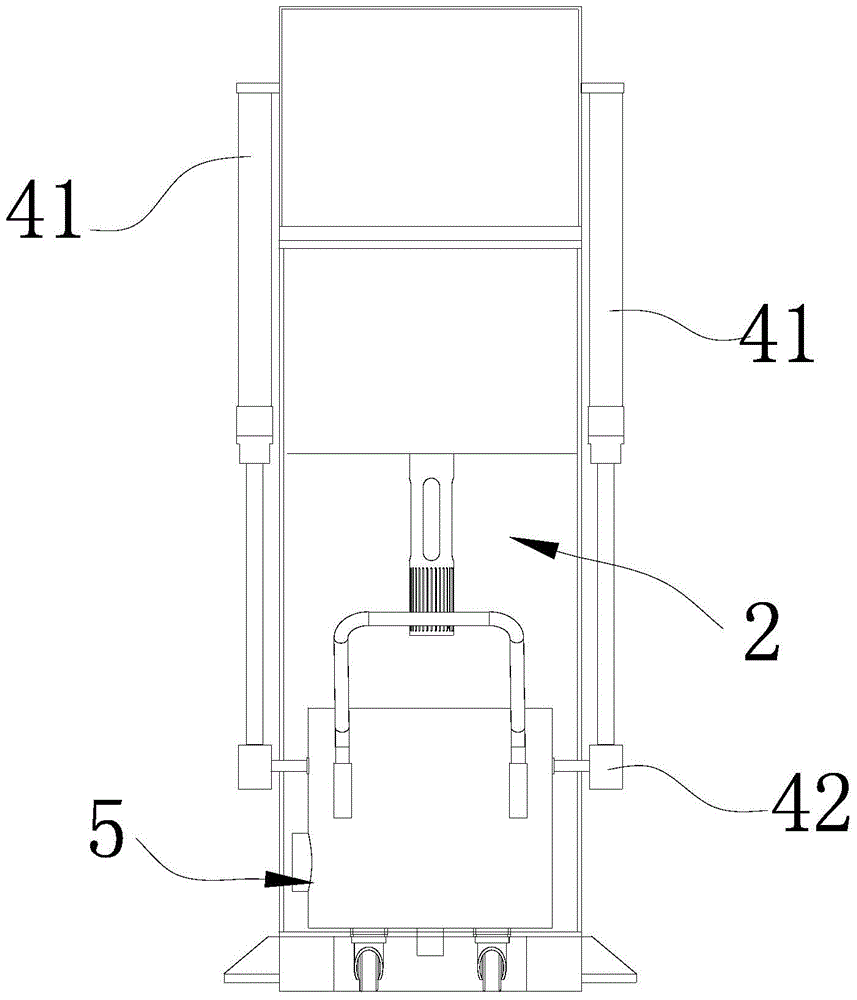

[0025] see figure 2 , the lifting device 4 includes two hydraulic cylinders 41, which are arranged on the base 1 corresponding to the two sides of the high-efficiency dispersion and mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com