A kind of preparation method of titanium dioxide composite material hollow sphere

A technology of titanium dioxide and nano-titanium dioxide is applied in the directions of titanium dioxide, microsphere preparation, chemical instruments and methods, etc., to achieve the effects of convenient operation, reducing pollution and improving filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

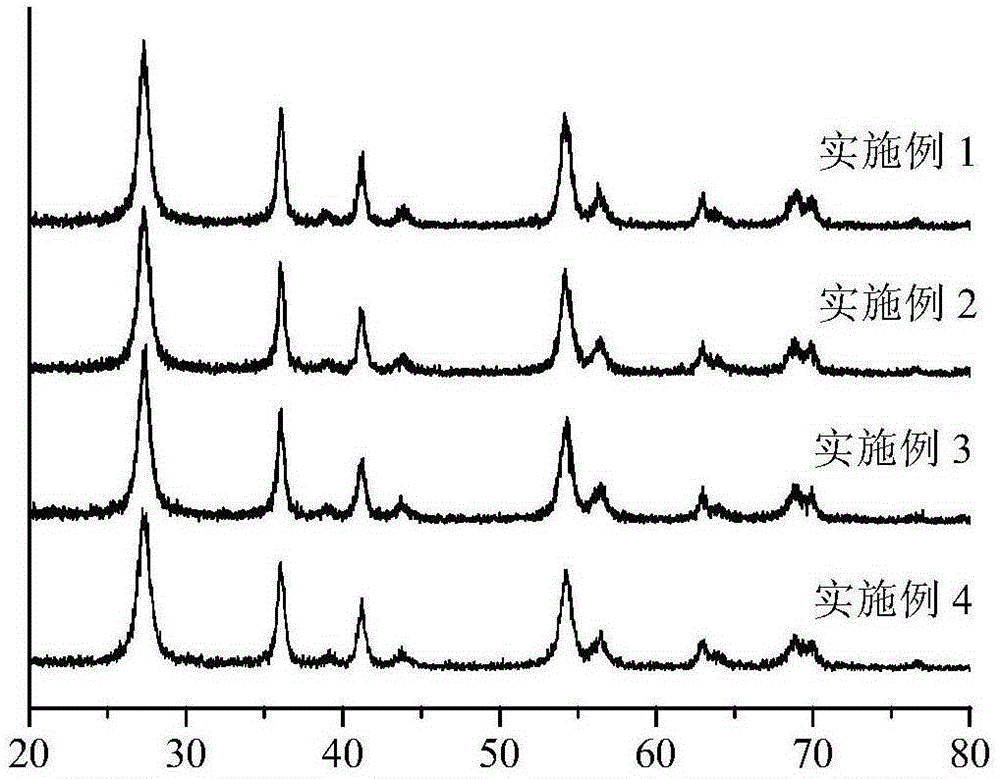

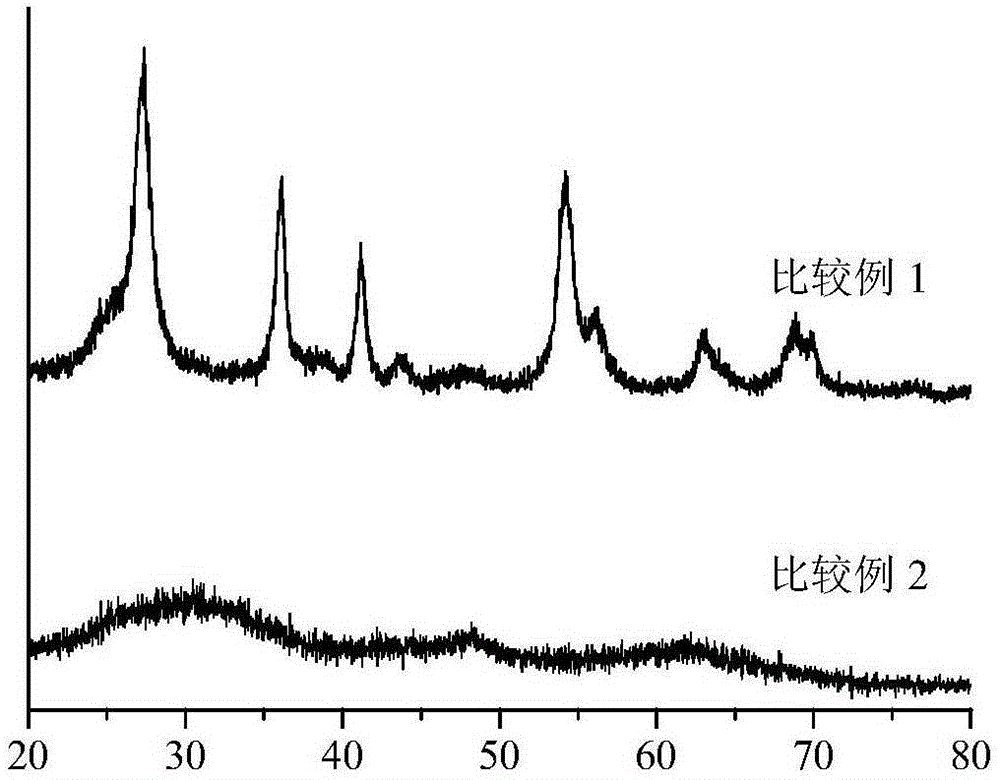

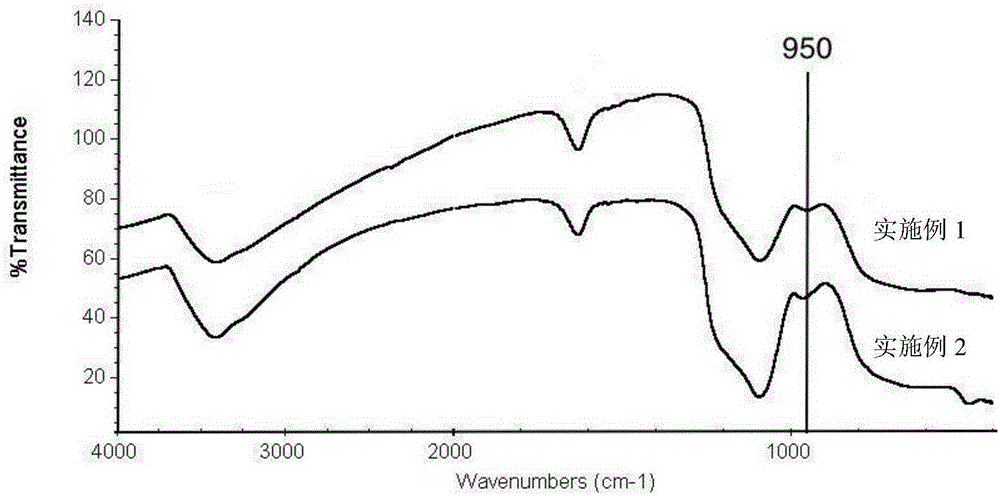

Embodiment 1

[0025] Step 1: take 150 grams of spherical calcium carbonate whose particle diameter is 300~500nm, add 850 grams of deionized water, be mixed with mass percentage concentration 15% calcium carbonate suspension, calcium carbonate suspension (pH value 9.0) be warmed up to 75°C, while stirring, add 0.5mol·L to the suspension -1 Sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 (0) solution and the carbon dioxide gas that feeds into the mole percentage composition is 40%, and other components are air in the gas, maintains 75 ℃ of system temperature, after 2 liters of sodium metasilicate solutions add, continue to feed carbon dioxide gas to the system The pH value is 7.2, and then the mixture is kept at 75° C. and stirred for 20 minutes to obtain a calcium carbonate suspension whose surface is coated with amorphous silicon dioxide.

[0026] Step 2: Adjust the temperature of the suspension in step 1 to 25°C, and add 2.5mol L to the suspension while stirring -1 Titanium tetrachlor...

Embodiment 2

[0030] Step 1: take 400 grams of spherical calcium carbonate whose particle diameter is 300~500nm, add 600 grams of deionized water, be mixed with mass percentage concentration 40% calcium carbonate suspension, calcium carbonate suspension (pH value 11.0) is warmed up to 95°C, while stirring, add 0.1mol·L to the suspension -1 Sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 (0) solution and the carbon dioxide gas that feeds into the molar percentage composition is 10%, and other components are air in the gas, maintains 95 ℃ of system temperature, after 3.33 liters of sodium metasilicate solutions are added, continue to feed carbon dioxide gas to the system. The pH value is 8.5, and then the mixture is kept at 95° C. and stirred for 60 minutes to obtain a calcium carbonate suspension whose surface is coated with amorphous silicon dioxide.

[0031] Step 2: Adjust the temperature of the suspension in step 1 to 50°C, and add 0.1mol L to the suspension while stirring -1 Titaniu...

Embodiment 3

[0035] Step 1: take 300 grams of spherical calcium carbonate whose particle diameter is 300~500nm, add 700 grams of deionized water, be mixed with mass percentage concentration 30% calcium carbonate suspension, calcium carbonate suspension (pH value 10.0) be warmed up to 88°C, while stirring, add 0.2mol·L to the suspension -1 Sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 (0) solution and the carbon dioxide gas that feeds into the mole percentage composition is 25%, and other components are air in the gas, maintains 88 ℃ of system temperature, after 5 liters of sodium metasilicate solutions add, continue to feed carbon dioxide gas to the system. The pH value is 8.0, and then the mixture is kept at 88° C. and stirred for 30 minutes to obtain a calcium carbonate suspension whose surface is coated with amorphous silicon dioxide.

[0036] Step 2: Adjust the temperature of the suspension in step 1 to 32°C, and add 1.5mol L to the suspension while stirring -1 Titanium tetrachl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com