Low bed reinforced surface flow constructed wetland system and operation methods thereof

A technology of constructed wetland system and border surface, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. The effect of low cost, increased diversity, and convenient operation, maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

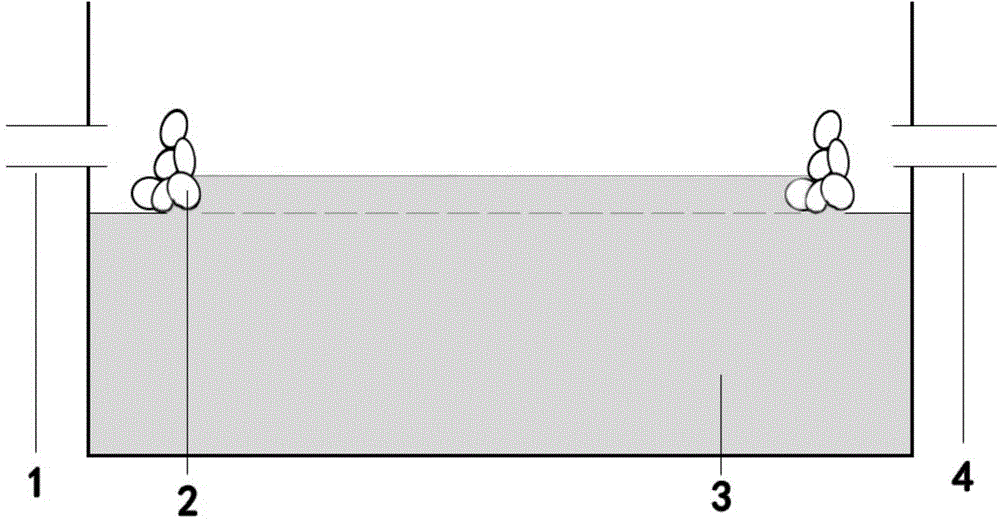

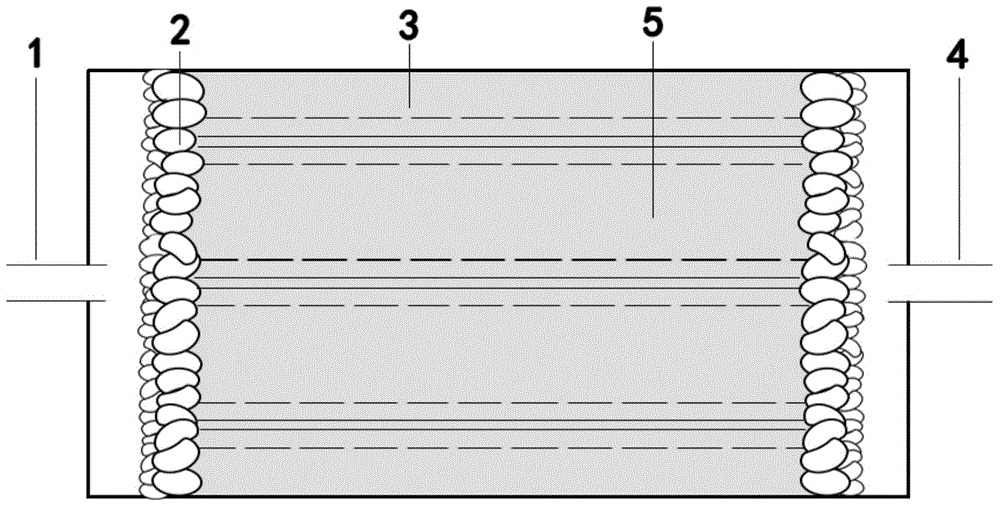

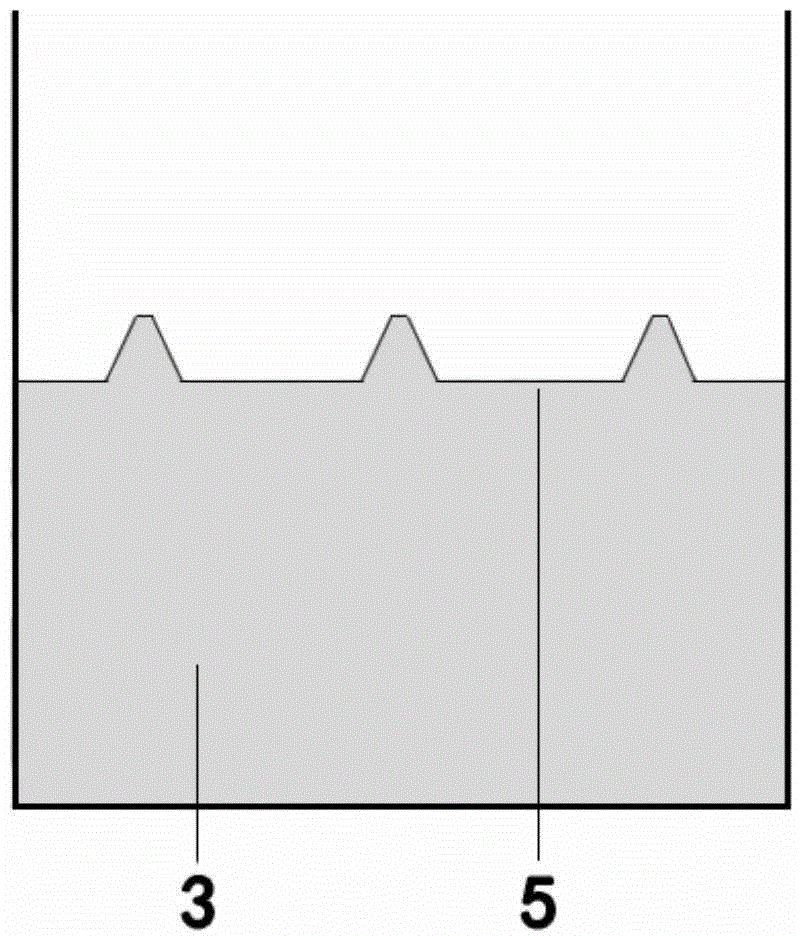

[0027] The low-row type surface flow constructed wetland system of the present invention has a structure such as figure 1 , figure 2 and image 3 shown. It includes water inlet pipe 1, water distribution weir 2, bed body 3, water outlet weir and water outlet pipe 4. The bed body 3 is made of concrete and is rectangular in shape with an aspect ratio of 1.8-2.0:1. The length and width are determined according to actual conditions, and the depth is 1.2-1.3m. The bed body 3 is filled with matrix (light loam and medium loam) and compacted to a filling depth of 0.6-0.7m. A water inlet pipe 1 and a water outlet pipe 4 are respectively arranged on both sides of the bed body 3 in the length direction at about 0.3 m above the substrate surface. The two sides of the length direction of the bed body 3 are respectively provided with a water distribution weir 2 and an outlet weir, both of which are triangular weirs with a height of 0.4-0.45m piled up by gravel or stones with a particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com