Method for removing polyaromatic hydrocarbon pollutants from camellia oil

A polycyclic aromatic hydrocarbon and process method technology, which is applied in the directions of fat oil/fat production and fat production, can solve problems such as uneven drying temperature of tea seeds, shorten the production and processing cycle, reduce the processing cost, and avoid the blank making process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

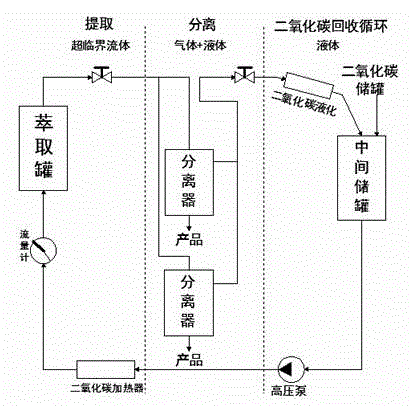

[0019] A process for removing polycyclic aromatic hydrocarbon pollutants in camellia oil. Firstly, the raw material camellia seeds are removed, and then dried at a low temperature at a temperature below 70°C, then shelled and crushed, and then extracted with supercritical carbon dioxide. Extraction is carried out in the device, and described extraction comprises the following steps:

[0020] a. Correctly connect the power cord, add water to the freezing box and heating box to 2-3cm from the box cover, and set the pressure of the carbon dioxide bottle at 5-6MPa;

[0021] b. Put the processed tea seed powder into the extraction tank, turn on the main power supply, refrigeration, and cold cycle switches in turn, start refrigeration, then set the temperature of the extractor and separator Ⅰ and Ⅱ, and start the process of rising / variable temperature operation;

[0022] c. Open the carbon dioxide intake valve, and observe that the pressure of the carbon dioxide storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com