A composite flooding experimental method of alternately injecting gel and polymer solutions after polymer flooding and subsequent water flooding

A polymer solution, alternate injection technology, applied in earth-moving drilling, production fluid, wellbore/well components, etc., can solve the problem of low oil recovery, avoid sticky fingering phenomenon, short oil displacement time, The effect of slowing the ascent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

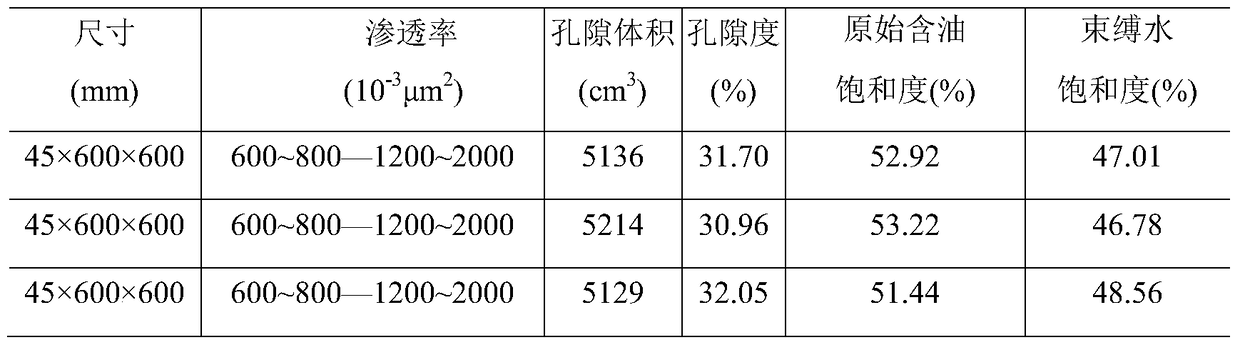

[0034] (1) After evacuating the cast model for 6 hours, saturate the artificially synthesized brine, and measure the porosity;

[0035] (2) Place the model saturated with artificially synthesized brine in an incubator at a constant temperature (45°C) for 12 hours or more;

[0036] (3) Oil flooding until the model does not produce water, then determine the original oil saturation;

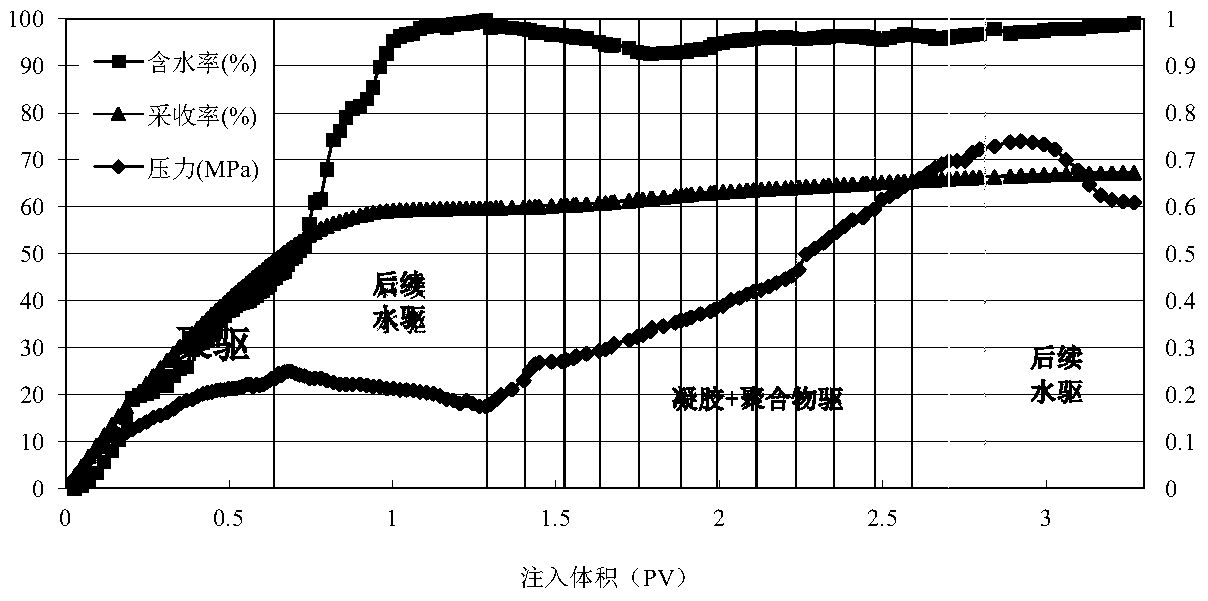

[0037] (4) Use conventional sewage, 25 million ultra-high molecular weight, concentration of 1200mg / L (viscosity 40-50mPa.s, viscosity 20-25mPa.s after shear dilution) to drive oil, injection speed is 3mPa.s min, the injection rate is 0.60PV, and then water flooding to 98% water cut, calculate the recovery factor of polymer flooding + subsequent water flooding;

[0038] (5) inject 0.03PV gel system slug;

[0039] (6) Inject a slug of surfactant solution of 0.03PV, and record liquid production and oil production;

[0040] (7) Carry out multiple rounds of parallel experiments according to the exper...

Embodiment 2

[0043] (1) After evacuating the cast model for 6 hours, saturate the artificially synthesized brine, and measure the porosity;

[0044] (2) Place the model saturated with artificially synthesized brine in an incubator at a constant temperature (45°C) for 12 hours or more;

[0045] (3) Oil flooding until the model does not produce water, then determine the original oil saturation;

[0046] (4) Use conventional sewage, 25 million ultra-high molecular weight, concentration of 1200mg / L (viscosity 40-50mPa.s, viscosity 20-25mPa.s after shear dilution) to drive oil, injection speed is 3mPa.s min, the injection volume is 0.64PV, after which the water is flooded to a water cut of 98%, and the recovery factor of polymer flooding is calculated;

[0047] (5) inject 0.02PV gel system slug;

[0048] (6) Inject a polymer solution slug of 0.02PV, and record liquid production and oil production;

[0049] (7) Carry out multiple rounds of parallel experiments according to the experimental pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com