Pressure sensor fixing mechanism

A technology of pressure sensors and fixing mechanisms, which is applied in the direction of conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low degree of automation, difficulty in ensuring product bonding strength and quality, and inability to improve production efficiency. Achieve the effects of compact structure, solving the instability of pressure control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

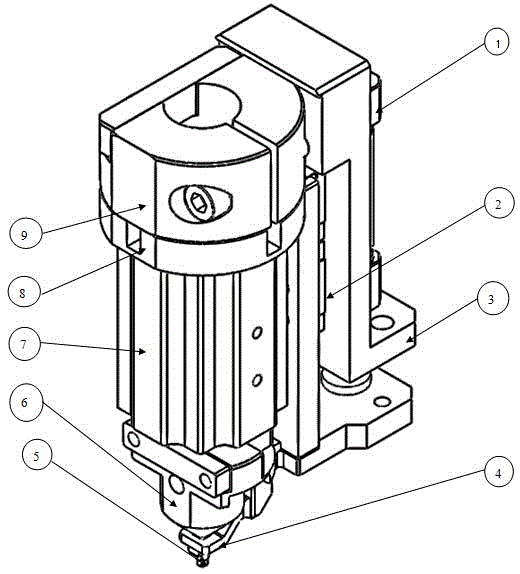

[0014] The pressure sensor 8 fixing mechanism includes a cylinder 1, a linear slide rail 2, a fixed plate 3, a peeling pressure head 4, a suction head 5, a fixed guide sleeve 6, a spline 7, a pressure sensor 8, and an elastic member 9, and is characterized in that the cylinder 1 Set on the fixed plate 3, the fixed plate 3 is connected with the spline 7 through the linear slide rail 2, the elastic part 9 is arranged above the spline 7, and the pressure sensor 8 is arranged between the spline 7 and the elastic part 9, and the bottom of the spline 7 The bottom fixed by the fixed guide sleeve 6 has a peeling pressure head 4 , and a suction head 5 is arranged below the peeling pressure head 4 . The elastic member 9 is a compression spring. The section of the fixing plate 3 presents a "Z" shape. The corner of the "Z" shape of the fixed plate 3 section is 90 degrees.

[0015] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com