Laser for realizing 2-micron waveband tuning narrow linewidth laser output

A laser and wide tuning technology, applied in the field of lasers, can solve the problems of narrow tuning range of 2μm band lasers, achieve wide tuning continuous laser output, large energy level splitting, and solve the effect of narrow tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

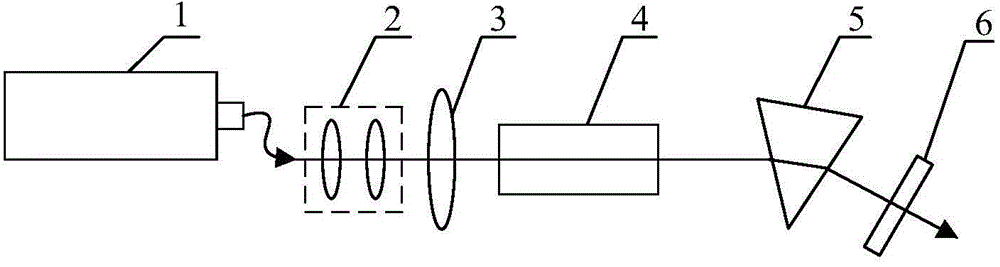

[0017] Implementation Case 1: Combining figure 1 , the present invention includes a laser pump source 1, a coupling focusing system 2, an input mirror 3, a laser crystal 4 and an output mirror 6, and a wavelength modulation prism 5 is also arranged between the laser crystal 4 and the output mirror 6, and the laser crystal 4 It is Ho:SSO crystal. The pump light emitted by the laser pump source 1 enters the Ho:SSO crystal 4 through the coupling focusing system 2 and the input mirror 3 in sequence, and the laser generated by the Ho:SSO crystal 4 oscillates in the resonant cavity formed by the input mirror 3 and the output mirror 6, And output through the output mirror 6, the wavelength modulation prism 5 is located in the resonant cavity for continuous tuning of the laser wavelength, and the resonant cavity is a flat concave cavity. The output mirror 6 of the present invention is realized by a volume grating, and the pass bandwidth of the volume grating coating is 200nm; the las...

Embodiment example 2

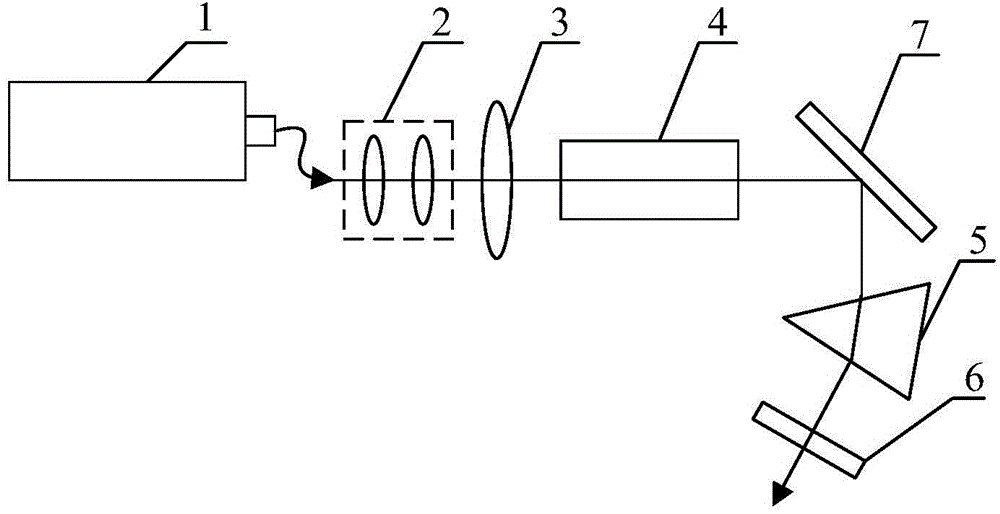

[0019] Implementation Case 2: Based on the above implementation cases combined with image 3 , the present invention can also be: a 45° reflector 7 is arranged between the laser crystal 4 and the wavelength modulation prism 5, that is, an "L" type resonant cavity is used, and the 45° reflector 7 is used to The light is reflected at 45°. It can change the transmission direction of the pump light and the laser beam in the cavity, effectively reduce the physical cavity length of the laser, save the overall volume of the laser, and can also effectively filter the pump light to prevent the laser and pump light from being output at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com