Powdery refreshing composition

A composition and cooling agent technology, applied in the field of powdered cooling agent compositions, can solve the problem of no long-lasting cooling sensation and the like, and achieve the effects of continuous improvement of cooling sensation, excellent operability, and enhancement of cooling sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

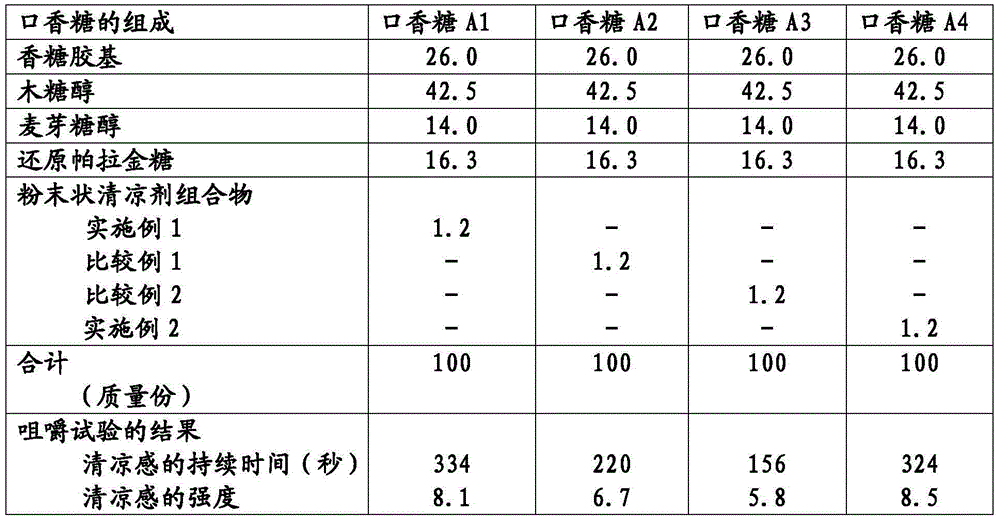

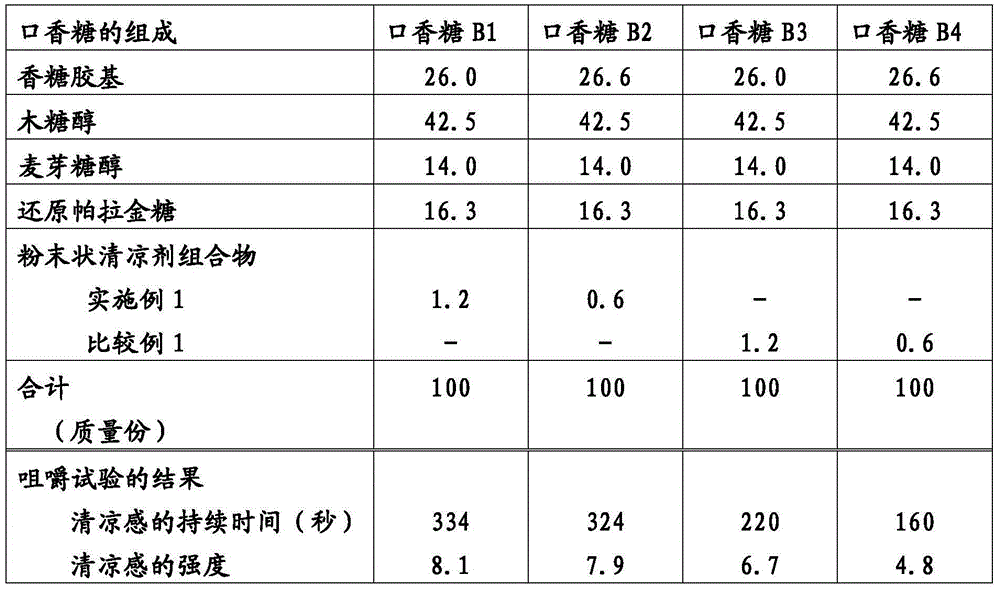

Examples

preparation example Construction

[0063] (1) Preparation of emulsified mixture

[0064] In 150 parts by mass of water, dissolve 10 to 50 parts by mass of the above-mentioned cooling substance, 20 to 80 parts by mass of a stabilizer, and 0 to 50 parts by mass of a high-intensity sweetener depending on the situation, and use a homomixer or high-pressure homogenizer Homogenize with a mixer such as a mixer to obtain a mixture.

[0065] (2) Powderization by spray cooling method

[0066] Powderization is performed by bringing the obtained mixture into contact with a low-temperature air current in an atomized state. The spray cooling granulation of the emulsified mixture can be done by a generally known method, and the fine liquid droplets sprayed by the nozzle atomizer (sprayer) or the disc atomizer are cooled and solidified by the cooling wind flowing through the cooling tower to obtain Coolant composition in powder form. It should be noted that by appropriately selecting spraying conditions, specifically, by ap...

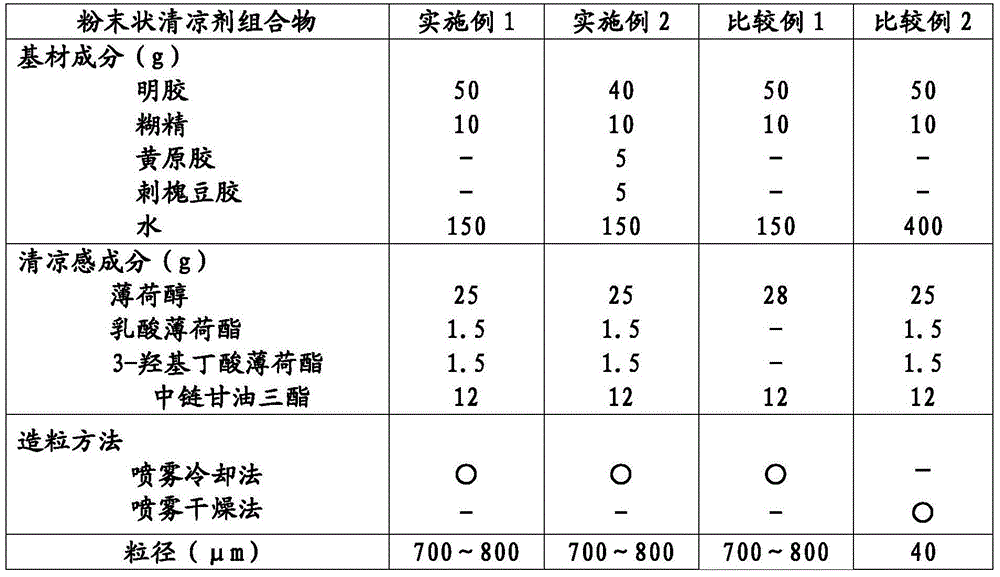

Embodiment 1

[0100] The base material component which melt|dissolved 50 g of gelatin and 10 g of dextrin in 150 g of water was sterilized by heating to 85 degreeC, and it cooled to 40 degreeC.

[0101] A cooling sensation component containing 25 g of l-menthol, 12 g of medium-chain triglycerides, 1.5 g of menthyl lactate, and 1.5 g of menthyl 3-hydroxybutyrate was added to the base component, and an emulsifier manufactured by M Technique was used. "CLEARMIX (trade name)" was homogenized at 18000 rpm.

[0102] The obtained liquid is used as a mixed liquid raw material, and spray cooling is carried out at a temperature in the cooling tower below -70° C. using a spray cooling method to obtain a powder or granule.

[0103] Next, it is thawed to below 0°C, and then dried through a fluidized bed using dehumidified air below 30°C.

[0104] By sieving, 85 g of powdery cooling agent compositions having a particle size of 700 to 800 μm were obtained.

Embodiment 2

[0112] Except using 40 g of gelatin, 5 g of xanthan gum, 5 g of locust bean gum, 10 g of dextrin, and 150 g of water as base components, a powdered refreshing powder with a particle size of 700 to 800 μm was produced by the same method as in Example 1. Dosage composition 85g.

[0113] [Table 1] Examples 1-2, Comparative Examples 1-2

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com