Cool elastic denim fabric and preparation method thereof

A denim fabric, elastic technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of short coolness retention time, poor coolness, single fabric function, etc., to achieve good comfort, good heat dissipation and Elasticity and good comfort effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

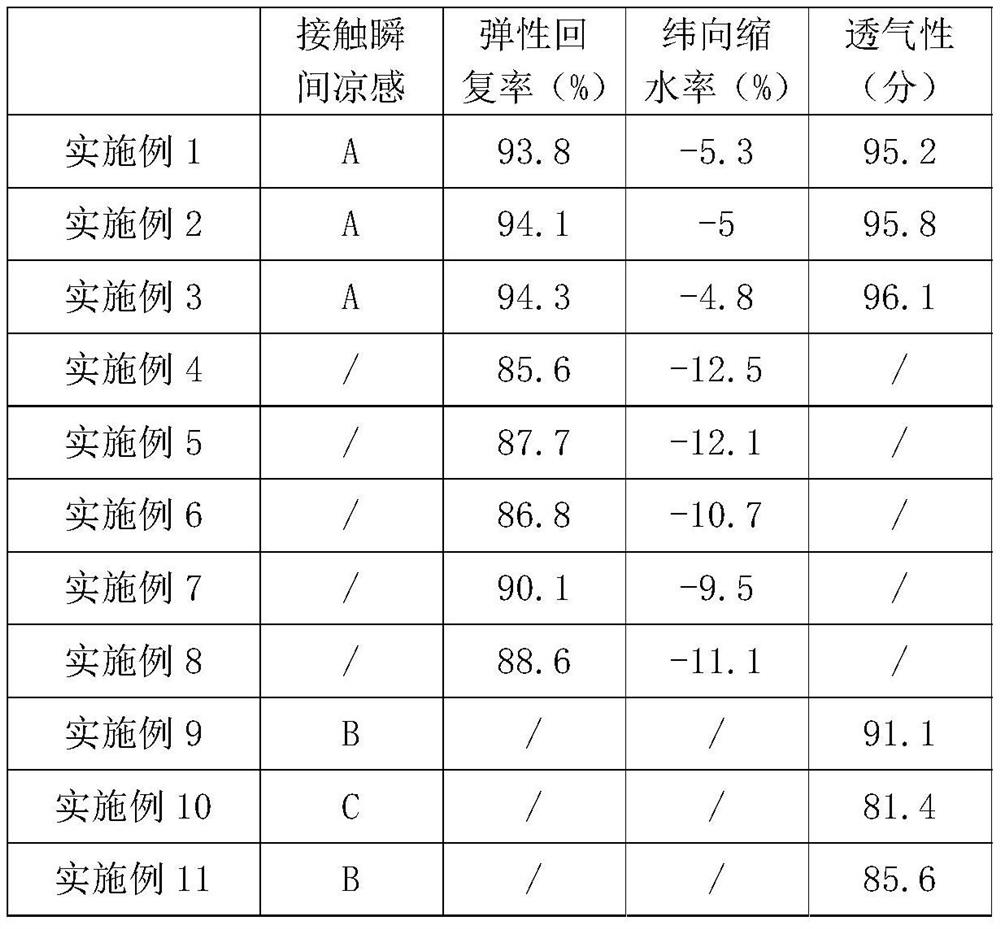

Examples

preparation example Construction

[0027] The preparation method of described functional spandex comprises the following steps:

[0028] (1) Weighing of raw materials: take functional jade powder, isocyanate, oligomer diol, chain extender, auxiliary agent, solvent, chain terminator of corresponding weight parts, and set aside;

[0029] (2) Preparation of functional jade powder slurry: circularly grind functional jade powder, additives and solvent in a grinder for 30-40 hours to obtain dispersed functional jade powder slurry;

[0030] (3) Preparation of prepolymer solution: Stir and mix isocyanate and oligomer diol at 70-80°C for 1-2h to prepare prepolymer; after cooling the prepolymer to 40-60°C, add A solvent is prepared to obtain a prepolymer solution with a mass concentration of 36-40%;

[0031] (4) Preparation of polyurethane urea: Dissolve the chain extender and chain terminator in the solvent to form a reaction solution with a mass concentration of 7.2-8%, and add the reaction solution to the prepolymer ...

Embodiment 1

[0096]Embodiment 1 of the present invention provides a cool feeling elastic denim fabric, the denim fabric is formed by interweaving warp yarns and weft yarns, the warp yarns are composed of first component warp yarns and second component warp yarns, the first group of The warp yarn is a yarn blended with functional spandex, cotton fiber, and bamboo fiber; the second component warp yarn is a yarn blended with cotton fiber and functional spandex; the weft yarn is blended with cotton fiber and bamboo fiber The blended yarn of the fiber includes functional spandex core-spun yarn; the raw materials for the preparation of the functional spandex include functional jade powder, isocyanate, oligomer glycol, chain extender, solvent, chain terminator, and auxiliary agent;

[0097] The preparation method of the functional spandex comprises the following steps: (1) Weighing of raw materials: Weigh functional jade powder, isocyanate, oligomer glycol, chain extender, auxiliary agent, solvent...

Embodiment 2

[0111] Embodiment 2 of the present invention provides a cool feeling elastic denim fabric, the denim fabric is formed by interweaving warp yarns and weft yarns, the warp yarns are composed of first component warp yarns and second component warp yarns, the first group of The warp yarn is a yarn blended with functional spandex, cotton fiber, and bamboo fiber; the second component warp yarn is a yarn blended with cotton fiber and functional spandex; the weft yarn is blended with cotton fiber and bamboo fiber The blended yarn of the fiber includes functional spandex core-spun yarn; the raw materials for the preparation of the functional spandex include functional jade powder, isocyanate, oligomer glycol, chain extender, solvent, chain terminator, and auxiliary agent;

[0112] The preparation method of the functional spandex comprises the following steps: (1) Weighing of raw materials: Weigh functional jade powder, isocyanate, oligomer glycol, chain extender, auxiliary agent, solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com