Bagged edible fungus inoculating machine

An inoculation machine and edible fungus technology, applied in application, horticulture, botany equipment and methods, etc., can solve the problems of low degree of automation of the whole inoculation machine, unguaranteed inoculation quality, restricting the cultivation scale of shiitake mushrooms, etc. The effect of planting enthusiasm, reducing the degree of personnel participation, and reducing the amount of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

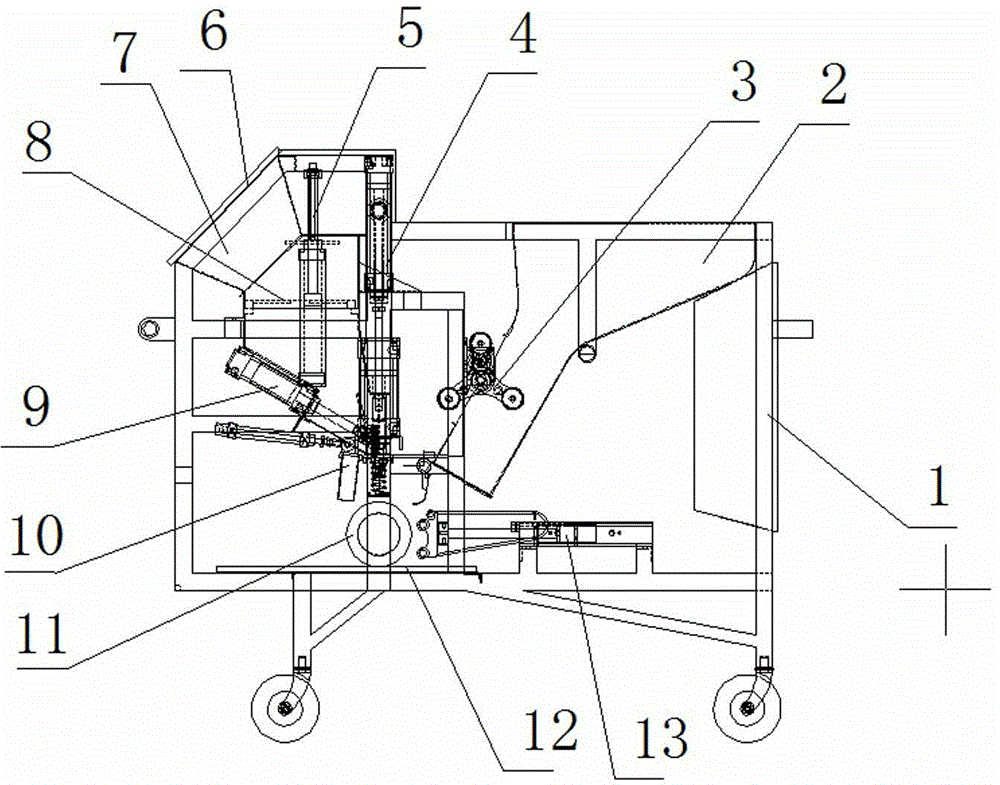

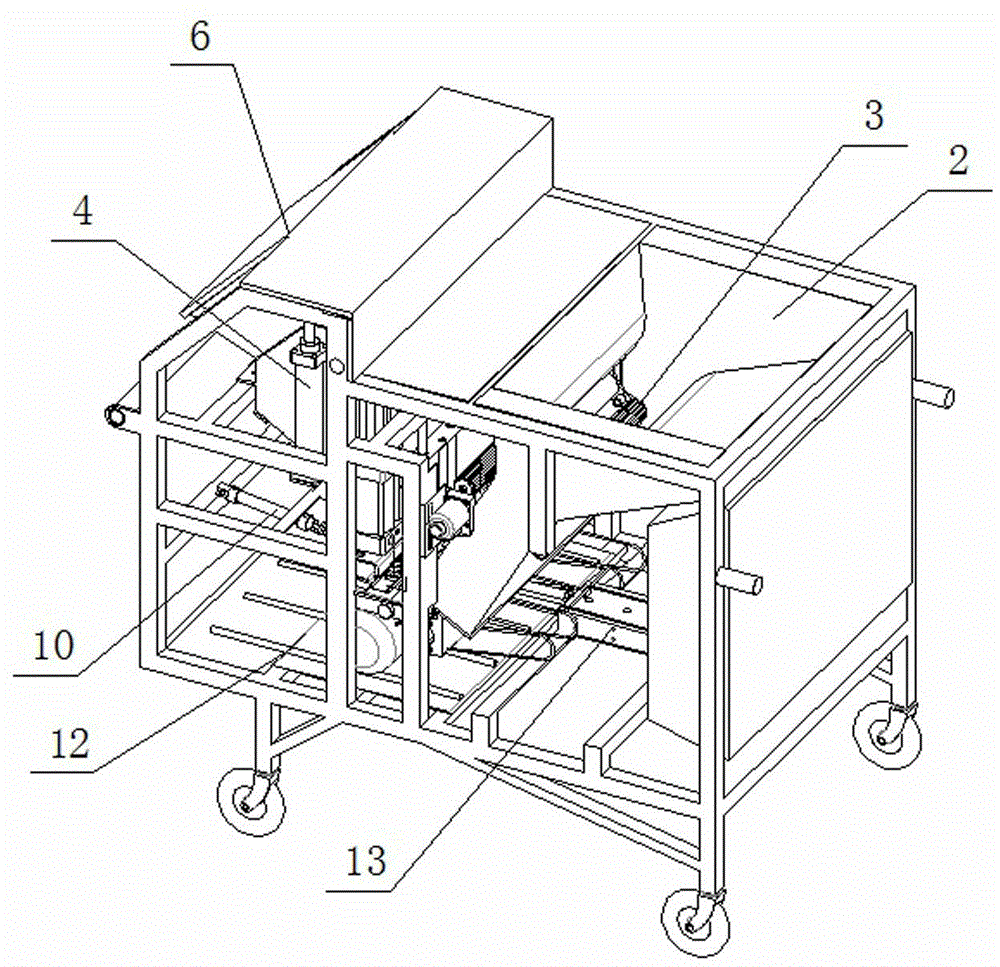

[0027] like figure 1 , 2 The bagged edible fungus inoculator shown has a frame 1 on which a culture medium hopper 2 is arranged, and a sorter 3 is arranged at the feeding channel of the culture medium hopper.

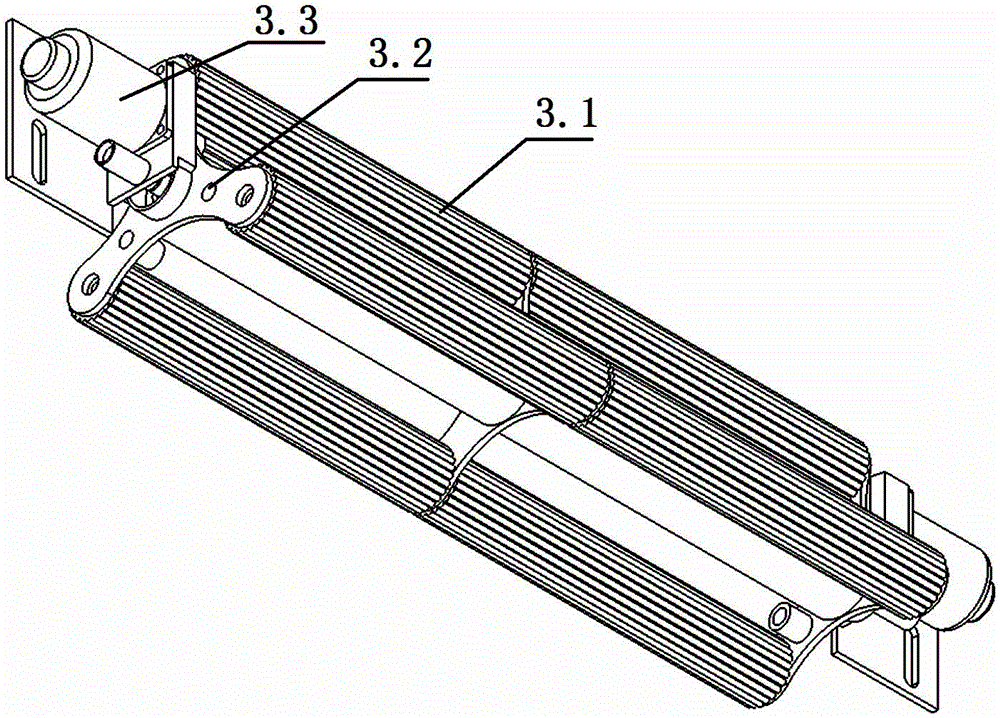

[0028] like image 3As shown, the sorter 3 has a Y-shaped shifting tooth hinged on the edge of the feeding channel, and the three protruding ends of the shifting tooth are hinged with rollers 3.1, and the sides of the three protruding parts of the shifting tooth are respectively provided with There is a locking hole 3.2, an electromagnet 3.3 is provided on the frame, and a locking pin is connected to the electromagnet drive, and the locking pin cooperates with the locking hole 3.2; When the tooth is rotating, when the locking hole corresponds to the locking pin, the locking pin snaps into the locking hole, and the shifting tooth stops rotating. When material needs to be unloaded, the action of the electromagnet drives the locking pin to release the locking of the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com