Food thermoforming device and food thermoforming process

A technology of hot pressing forming and hot pressing device, which is applied in the field of food hot pressing forming device and food hot pressing forming technology, which can solve the problems of unfavorable children and teenagers, unsafety, increasing food, etc., so as to reduce manual links and improve Production efficiency and the effect of less nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

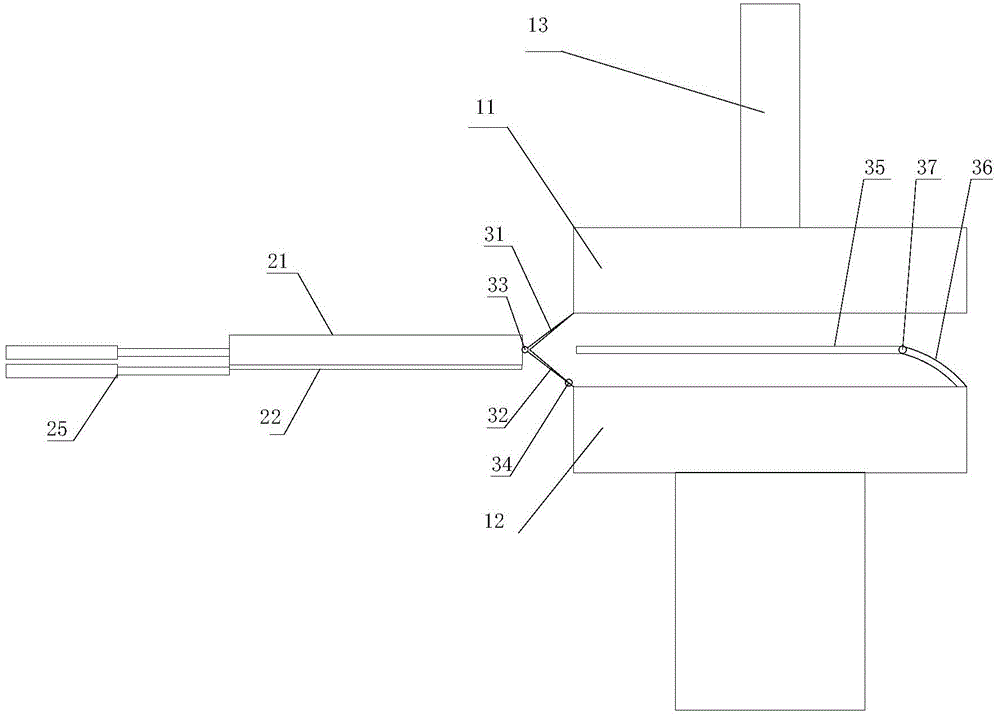

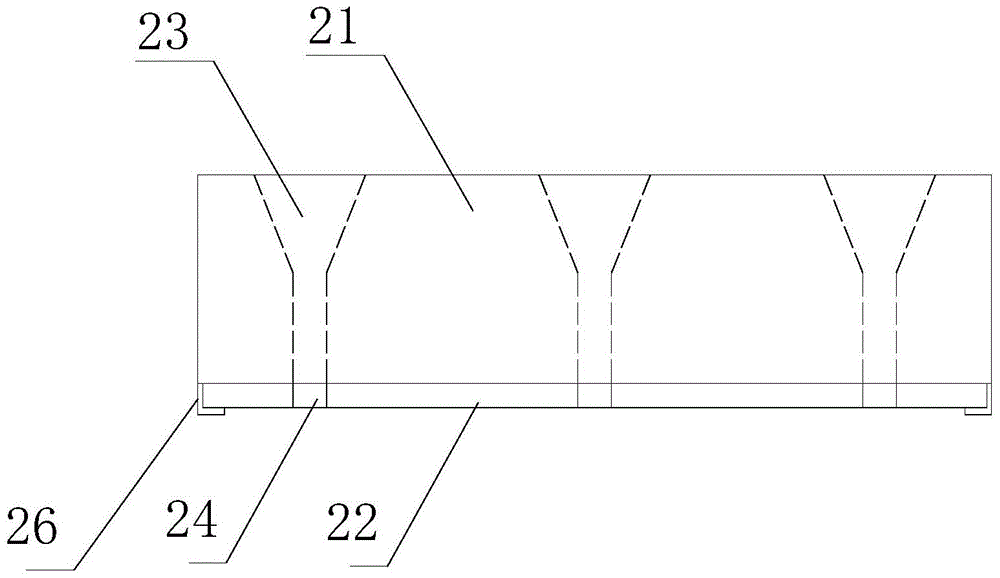

Embodiment 1

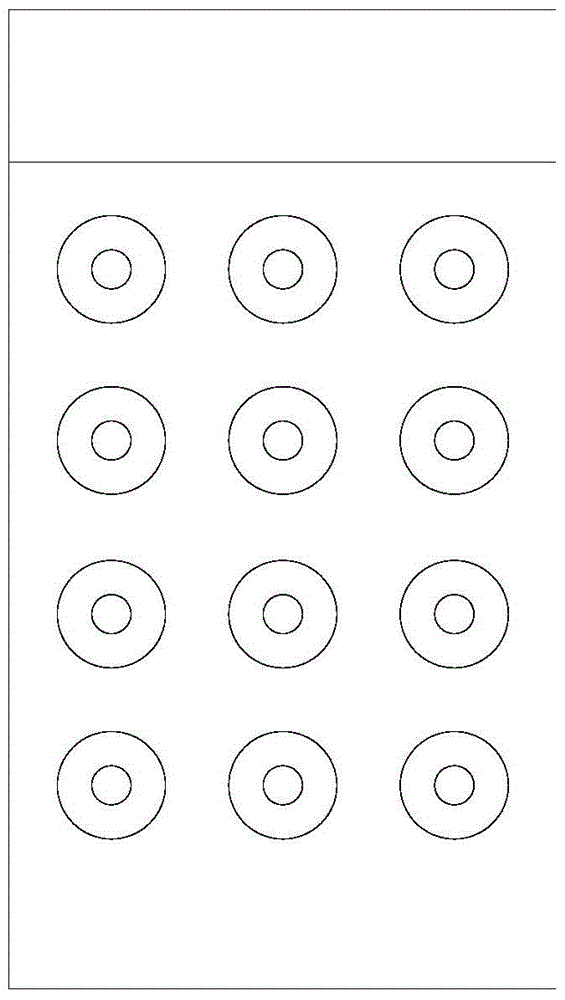

[0048] Embodiment 1: as Figure 6-9 Shown: it also includes a sorting device, the sorting device includes a feeding device, a uniform material device, a transmission path A42, a transmission path B43, and the described feeding device is a holding tray 41 with a vibrator. The bottom of the material holding tray 41 is provided with a number of outlets, and each outlet is connected with a corresponding transmission path A, and the uniform material device includes a rotating disk 44 with a rotating device, a cutting tray 45, and a discharging tray 46. The outer circumference of the turntable 44 is evenly distributed with an even number of the same specifications of the grid 47, the cutting plate 45 is located above the turntable 44 and covers the turntable 44 and the grid, the outer circumference of the cutting disc 45, and the odd number of The corresponding position of the material grid is provided with a material inlet 48 matching the opening size of the material grid. The disc...

Embodiment 2

[0050] Embodiment 2: as Figure 10-13 As shown: it also includes a sorting device. The sorting device includes a feeding device, an equalizing device, and a transmission path C. The described feeding device is a charging tray 51 with a vibrator, and the described equalizing device Consists of an equalizing plate 52, a cutting plate 53, and a blocking plate 54. The equalizing plate 52 is divided into several grids with the same specifications through the grid. The grids are divided into two types, one is a through hole formed completely through the top and bottom 55, the other is a sealed grid 56 with upper and lower openings 57 completely sealed. The charging tray 51 is located above the uniform tray 52 and communicates with the uniform tray 52. A cutting tray 53 is arranged on the upper surface of the uniform tray 52. The disc 53 is located on the plane where the charging disc 51 and the uniform disc 52 are connected, and the cutting disc 53 is arranged on the uniform disc ...

Embodiment 3

[0071] Step 1 Select ingredients (small dried fish, small dried fish belongs to long-shaped ingredients)

[0072] This batch uses small dried fish with a length specification ranging from 50 to 70 mm;

[0073] 2. Hot pressing: choose ingredients with a weight of 0.9g-1.5g, and place them in an environment with a weight of 300kg at 190-200 degrees (the heating temperature can be controlled, but it cannot be guaranteed to be constant and stable, so choose a suitable range value) , hot pressing, the hot pressing time is 2 to 3 seconds, and the thickness of the final product is 0.5 to 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com