Graphene/ chitosan compound micro-capsule and preparation method thereof

A technology of chitosan microcapsules and composite microcapsules is applied in the directions of microcapsules, capsule delivery, pharmaceutical formulations, etc., to achieve the effects of simple operation, mild conditions and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

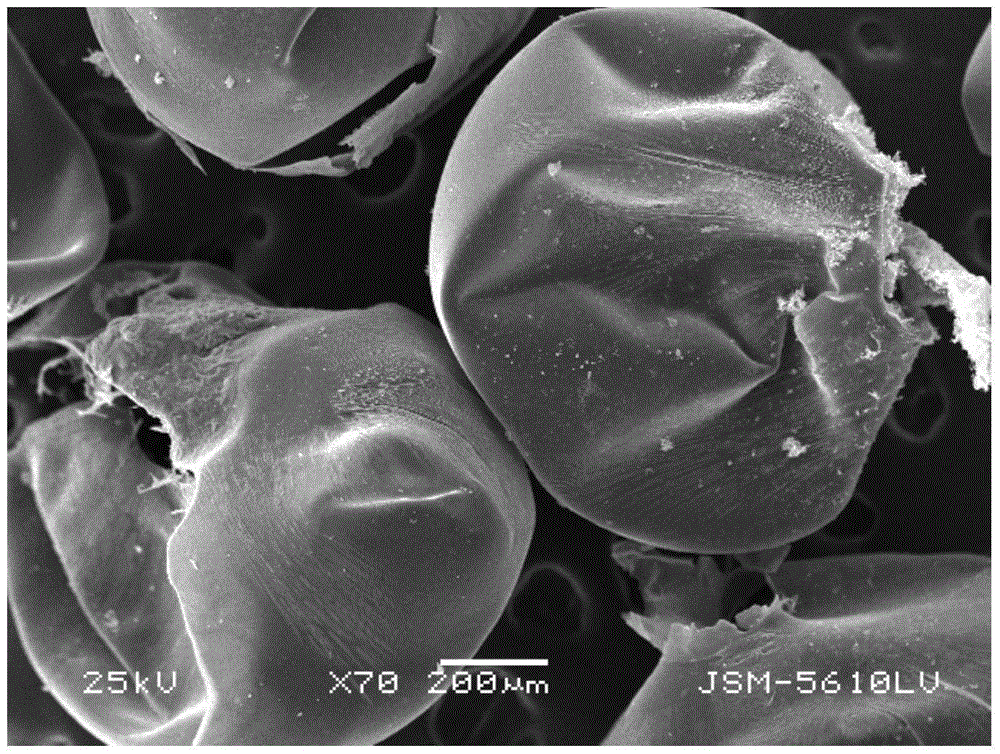

[0029] What this embodiment provides is a kind of in-situ introduction of graphene into the membrane wall of chitosan microcapsules, thus forming spherical graphene / chitosan composite microcapsules, with a size of 300-1000 μm and a particle size distribution Coefficient ≤ 6%.

[0030] Graphene is introduced into the membrane wall of the microcapsule, and the graphene effectively enhances the mechanical properties of the membrane wall of the composite microcapsule, and can regulate the release rate of the composite microcapsule to the loaded drug.

Embodiment 2

[0032] The preparation method of the composite microcapsules provided in this example first modifies graphene with chitosan quaternary ammonium salt to ensure that graphene can be stably dispersed in chitosan solution, and then based on the gas-liquid shearing effect in a self-made microfluidic device The mixed micro-droplets of graphene / chitosan are formed in the medium, and then dropped into the anionic surfactant solution, and the re-coagulation effect makes the graphene modified by chitosan quaternary ammonium salt and chitosan molecules precipitate together to form microcapsules Membrane wall, thereby obtaining graphene / chitosan composite microcapsules, graphene is introduced into the microcapsule membrane wall in situ.

[0033] Specific steps are as follows:

[0034] (1) prepare chitosan quaternary ammonium salt modified graphene:

[0035] Place the flask filled with 46ml of concentrated sulfuric acid (98%) in an ice-water bath and cool it to 0°C, take 2.0g of natural f...

Embodiment 3

[0041] Chitosan quaternary ammonium salt-modified graphene was prepared according to the steps in step (2) of Example 2, using the self-made microfluidic device in step (2) of Example 1. Add 2 g of chitosan to 10 mL of 0.2 mol / L acetic acid solution, stir at room temperature for 2 h to fully dissolve the chitosan, and let stand for 1 h after stirring to eliminate bubbles in the solution. The graphene modified by 5g chitosan quaternary ammonium salt is dispersed in 10mL water, then chitosan solution and modified graphene dispersion are mixed in a volume ratio of 10:2, then the mixed dispersion is controlled by a micro-injection pump to The flow rate of 3mL / h is passed into the circular capillary of the microfluidic device, N 2 As the external phase fluid, the gas is passed into the gap between the circular and square capillaries at a flow rate of 0.5 L / min. Under the action of gas shear, the mixed dispersion liquid forms micro-droplets at the outlet of the microfluidic device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com