Denitration, desulfurization and dust-removal device and method applying same

A technology for desulfurization, dust removal, and combustion of flue gas, which is applied in the field of air purification, can solve the problems of polluting the environment, unable to remove harmful gases simultaneously, and achieve high work efficiency, work efficiency and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments of the present invention are described in detail below.

[0035] air cleaning unit

[0036] Structure of the air cleaning unit

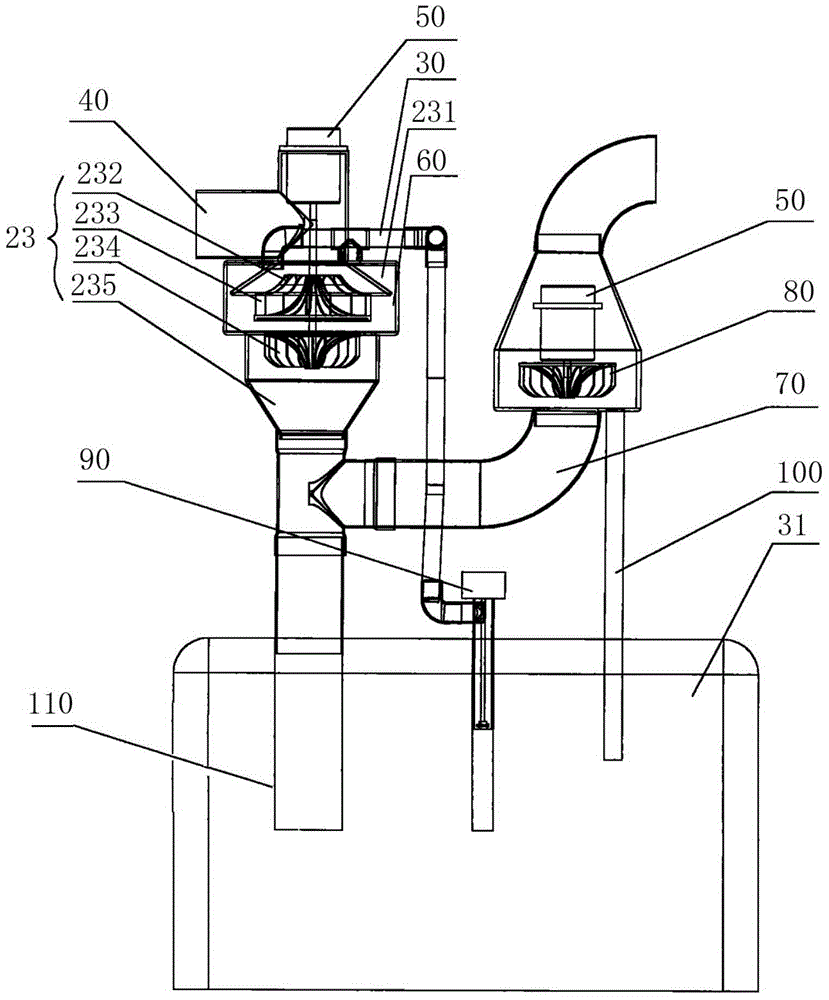

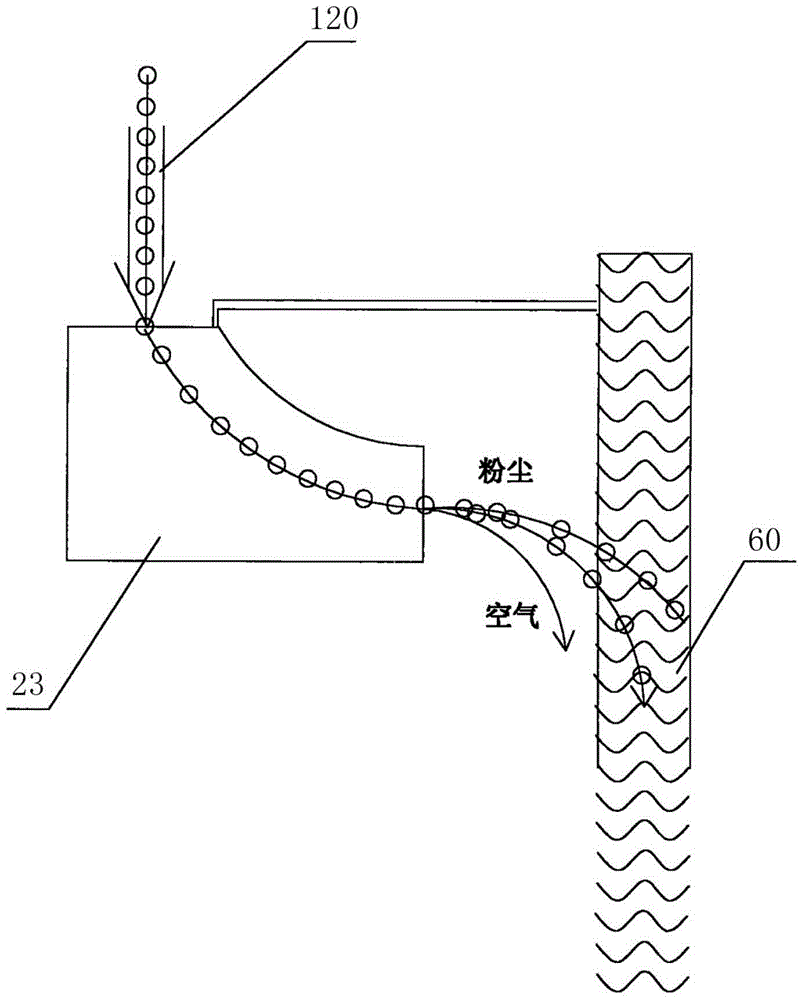

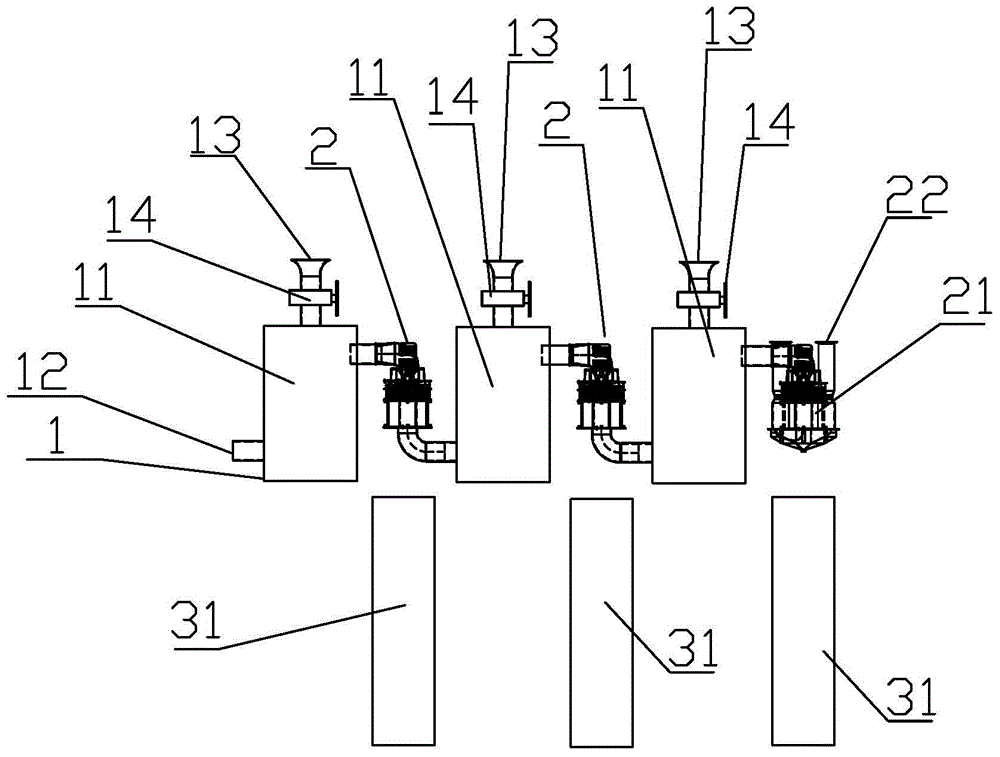

[0037] Such as figure 1 As shown, the air cleaning unit of the present invention includes an air cleaning unit cavity 231, the air cleaning unit cavity 231 is provided with a dusty air inlet pipe 2 and a water inlet pipe 30, and the motor 50 of the centrifugal assembly 23, the centrifugal assembly 23 includes a water separator 41 arranged from top to bottom, a centrifugal impeller 233 and a stirring impeller 43 with a reverse opening. Dust-laden air enters the centrifugal assembly through the air inlet pipe 2, and the external water or circulating water is formed under the action of the centrifugal assembly. The inner wall of the air cleaning unit cavity 231 is relied on, and the water curtain wall 60 coaxial with the centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com