Method for preparing monodispersed ultrafine particles

An ultra-fine particle and monodisperse technology, applied in the direction of nanotechnology, can solve the problems of large synthetic particles, poor dispersion, and inability to obtain ultra-fine particles, and achieve the effects of low cost, easy availability of raw materials, and long-term compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 0.2 g Fe(NO 3 ) 3 (analytical pure) put in a beaker, add distilled water to dilute to 0.5%, mix well to get a solution;

[0036] (2) Put the above solution into the container of the aerosol generator, turn on the microwave oven, and adjust the microwave power to 700 w;

[0037] (3) Open the nitrogen cylinder and adjust the pressure of the aerosol generator to 20 psi. The aerosol particles produced by the aerosol generator enter the microwave oven for microwave irradiation, and the irradiation time is about 26 s;

[0038] (4) The particles after microwave action enter the tube furnace (the temperature is set at 400 ℃) for heat treatment for about 5 s;

[0039] (5) The heat-treated particles are collected on the filter, and the temperature of the filter is maintained at about 80 °C;

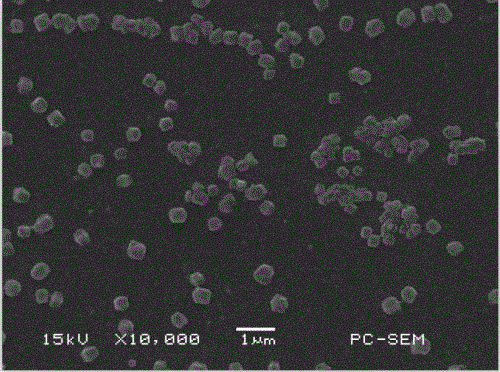

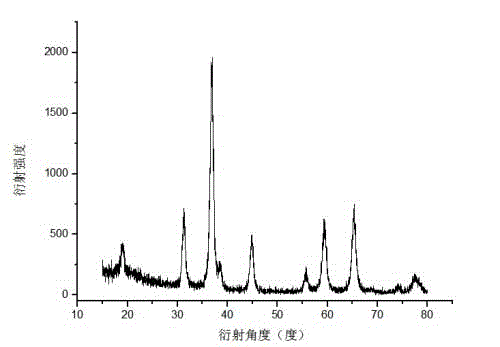

[0040] (6) Disperse the collected particles in absolute ethanol solution for SEM and XRD tests. The obtained monodisperse iron oxide particles are as follows: figure 1 , fig...

Embodiment 2

[0043] (1) Weigh 0.2 g AgNO 3 (analytical pure) put in a beaker, add a certain amount of distilled water to dilute to 0.5%, mix well to get a solution;

[0044] (2) Put the above solution into the container of the aerosol generator, turn on the microwave oven, and adjust the microwave power to 700 w;

[0045] (3) Open the nitrogen cylinder and adjust the pressure of the aerosol generator to 15 psi. The aerosol particles produced by the aerosol generator enter the microwave oven for microwave irradiation, and the irradiation time is about 50 s;

[0046] (4) The particles after microwave action enter the tube furnace (the temperature is set at 400 ℃) for heat treatment for about 5 s;

[0047] (5) The heat-treated particles are collected on the filter, and the temperature of the filter is maintained at about 80 °C;

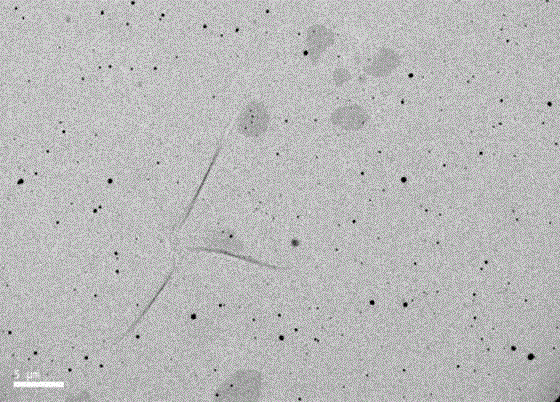

[0048] (6) Disperse the collected particles in absolute ethanol solution for SEM and XRD tests. The obtained monodisperse ultrafine silver particles are as follows...

Embodiment 3

[0051] (1) Weigh 0.2 g AgNO 3 (analytical pure) put in a beaker, add a certain amount of distilled water to dilute to 0.25%, mix well to get a solution;

[0052] (2) Put the above solution into the container of the aerosol generator, turn on the microwave oven, and adjust the microwave power to 800 w;

[0053] (3) Open the nitrogen cylinder and adjust the pressure of the aerosol generator to 40 psi. The aerosol particles produced by the aerosol generator enter the microwave oven for microwave irradiation, and the irradiation time is about 35 s;

[0054] (4) The particles after microwave action enter the tube furnace (the temperature is set at 400 ℃) for heat treatment for about 4 s;

[0055] (5) The heat-treated particles are collected on the filter, and the temperature of the filter is maintained at about 80 °C;

[0056] (6) Disperse the collected particles in absolute ethanol solution for DLS test. The test results are as follows: Figure 5 shown

[0057] It can be seen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com