A method for concentration and purification of graphene and graphene-based composite material dispersion

A technology of graphene dispersion and composite materials, which is applied in the field of nanomaterials, can solve the problems of high cost, residual impurities, and low efficiency, and achieve the effects of simple operation, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

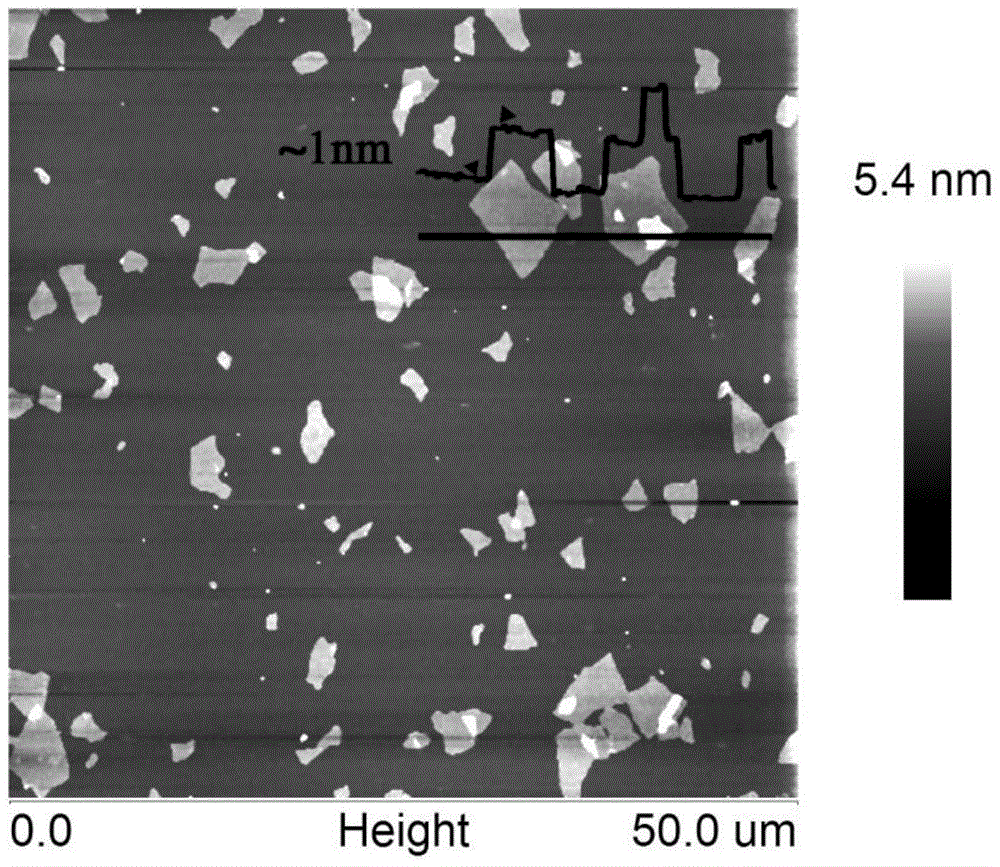

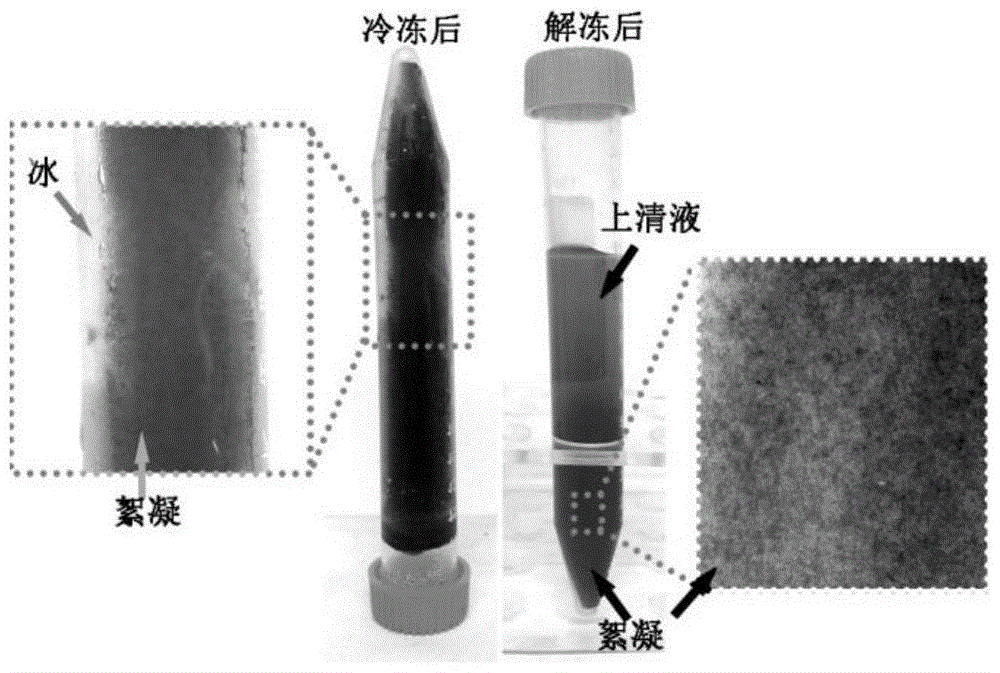

[0030] Example 1, the purification and concentration of graphene oxide aqueous dispersion is taken as an example:

[0031] Step 1: Pour the graphene oxide aqueous dispersion into a plastic bucket, place it in a refrigerator freezer (about -25 degrees Celsius), and let it stand for about 12 hours to completely freeze the dispersion;

[0032] Step 2: Place the plastic bucket in warm water to thaw, and let it stand for about 12 hours to completely settle the flocculated graphene oxide;

[0033] Step 3: Remove the supernatant liquid to obtain the graphene oxide concentrate of the lower layer;

[0034] Step 4: In order to improve the purity of the graphene oxide dispersion, water can be added to dilute, and the above freezing and concentration steps can be repeated, and the chloride ion impurity content in the dispersion will decrease by 20%-95%.

Embodiment 2

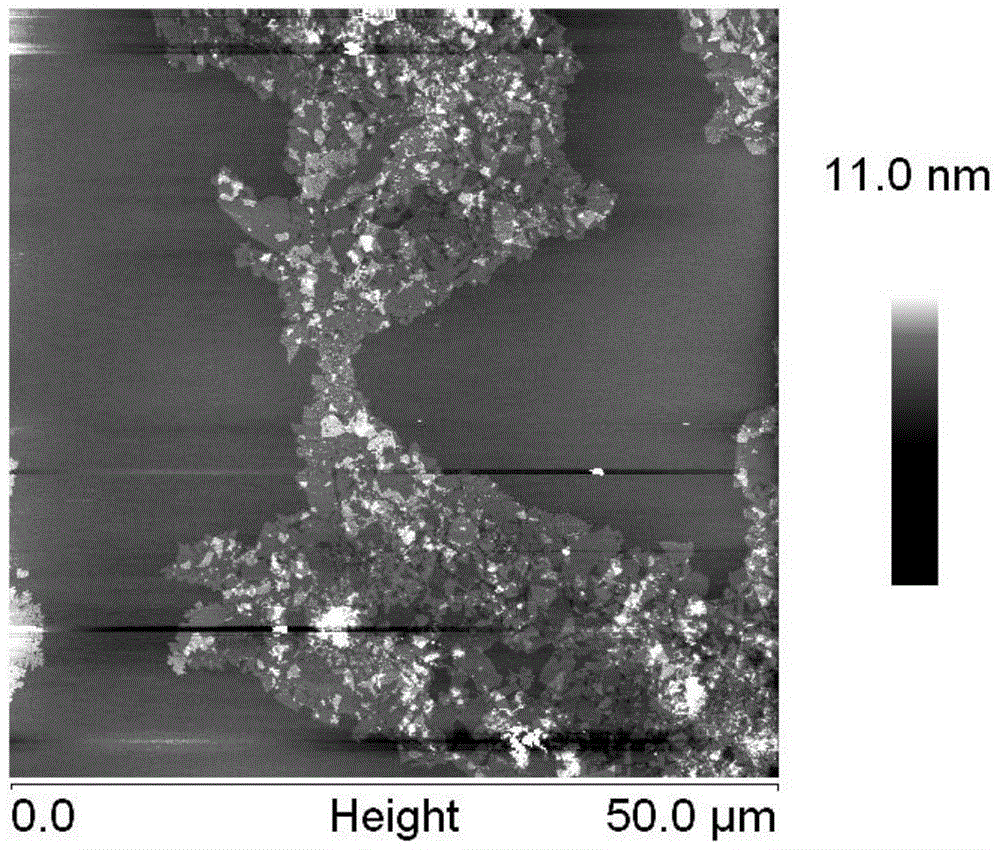

[0035] Example 2, the purification and concentration of the reduced graphene oxide dispersion is taken as an example:

[0036] Step 1: Use a mixture of 10% by volume of ethanol and water as the solvent. Pour the reduced graphene oxide dispersion into a plastic bucket, place it in a cold storage (about -25 degrees Celsius), and let stand for about 20 hours to make the dispersion Completely frozen

[0037] Step 2: Place the plastic bucket at room temperature to thaw completely, and let it stand for about 15 hours to completely settle the flocculated reduced graphene oxide;

[0038] Step 3: Remove the supernatant liquid to obtain the reduced graphene oxide concentrate of the lower layer;

[0039] Step 4: In order to improve the purity of the product, a 10% volume ratio ethanol and water mixed solution can be added to dilute, and the above freezing and concentration steps can be repeated.

Embodiment 3

[0040] Example 3, the purification and concentration of graphene oxide and manganese oxide composite material dispersion liquid is taken as an example:

[0041] Step 1: Pour the graphene oxide and manganese oxide composite material aqueous dispersion into a plastic bucket, place it in the refrigerator freezer (about -25 degrees Celsius), and let it stand for about 15 hours to completely freeze the dispersion;

[0042] Step 2: Place the plastic bucket in warm water to completely thaw, and let it stand for about 5 hours to fully settle the flocculated graphene oxide and manganese oxide composite material;

[0043] Step 3: Remove the supernatant liquid to obtain the concentrated liquid of the lower layer;

[0044] Step 4: To improve the purity of the product, deionized water can be added to dilute, and the above freezing and concentration steps can be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com