A method for cryopreserving two-dimensional nano-powder dispersion

A two-dimensional nanotechnology, cryopreservation technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex operation, high cost, low production efficiency, etc., and achieve simple process, low cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Add the prepared graphene powder at a ratio of 1 mg / ml to a mixed solution containing 30% by volume of ethanol and water, and sonicate for 3 hours.

[0031] Step 2: Centrifuge the graphene dispersion at a speed of 500 rpm for 45 minutes, and then transfer the supernatant.

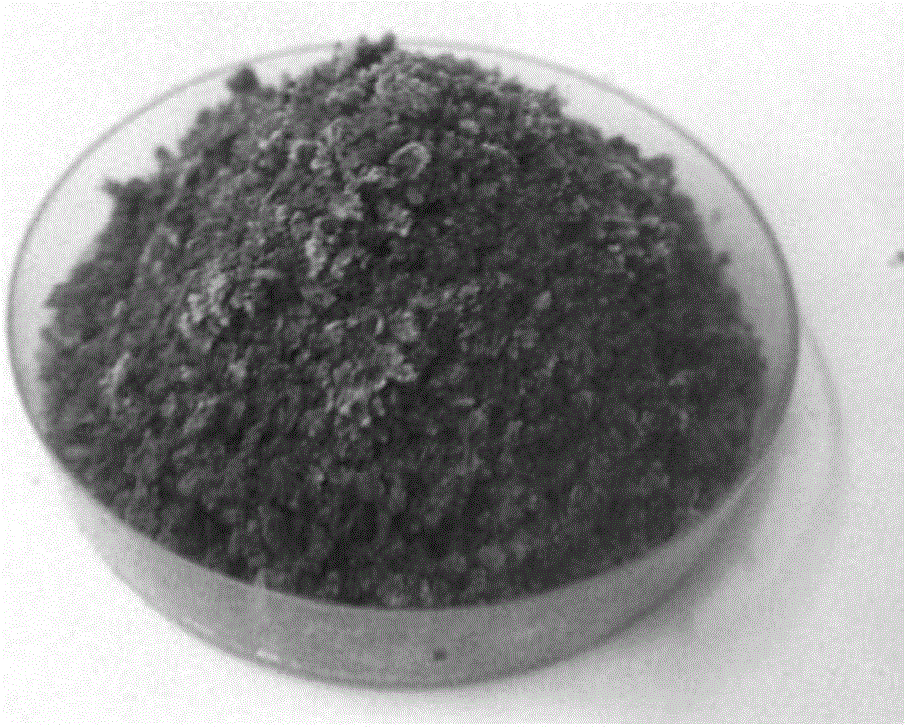

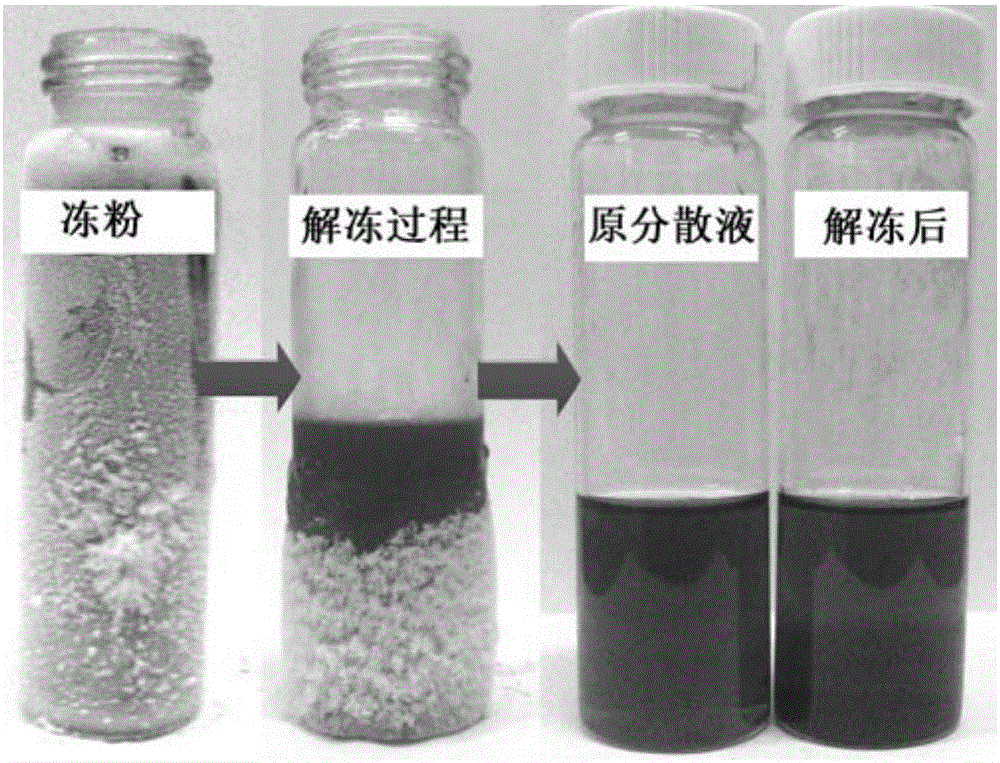

[0032] Step 3: Slowly pour the supernatant into a liquid nitrogen container, and at the same time stir rapidly with a glass rod to freeze powder.

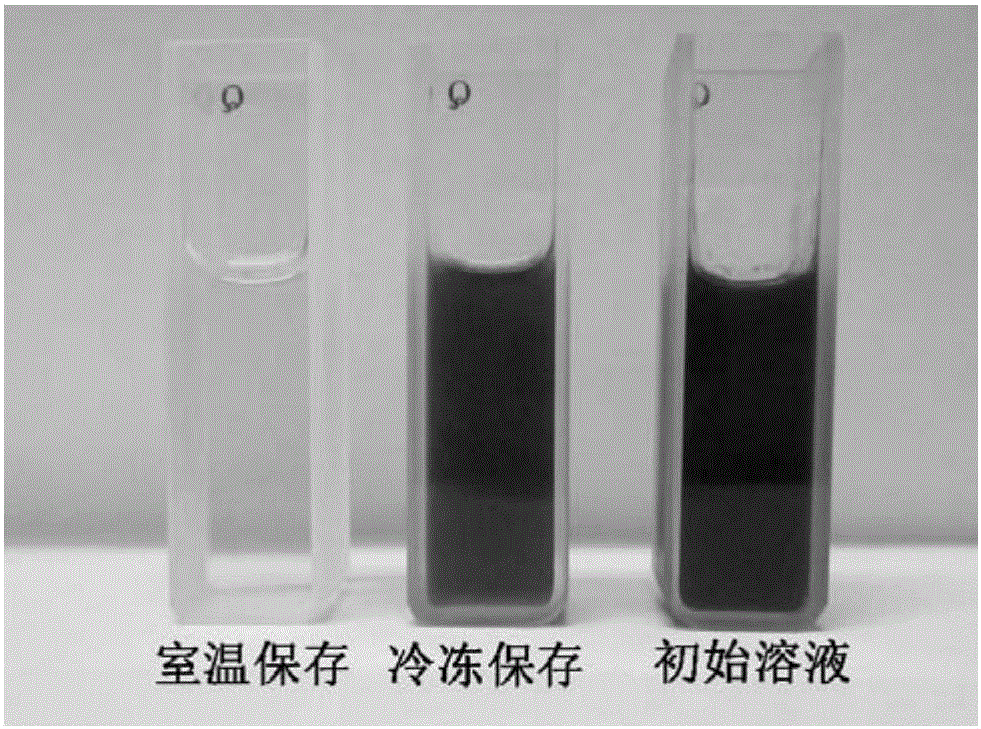

[0033] Step 4: Transfer the processed frozen powder into a plastic container, quickly place it in the freezer of an ordinary refrigerator, and store it at a temperature of about -18°C for 1 month.

[0034] Step 5: When in use, transfer the frozen powder to room temperature to thaw to form a graphene dispersion.

Embodiment 2

[0036] Step 1: Add 3 mg / ml hexagonal boron nitride powder to a mixed solution containing 40% volume ratio of isopropanol and water; use jet cavitation method to treat at 30 MPa for 3 hours.

[0037] Step 2: Centrifuge the boron nitride dispersion at a speed of 500 rpm for 45 minutes, and then transfer the supernatant.

[0038] Step 3: Slowly pour the supernatant into a liquid nitrogen container, and at the same time stir it with a glass rod to form a frozen powder.

[0039] Step 4: Transfer the processed frozen powder into a plastic container, quickly place it in the freezer of an ordinary refrigerator, and store it at a temperature of about -20°C.

[0040] Step 5: When in use, transfer the frozen powder to normal temperature to thaw to form a two-dimensional nano boron nitride dispersion.

Embodiment 3

[0042]Step 1: Add molybdenum disulfide powder at a ratio of 5 mg / ml to a mixed solution of acetone and water at a ratio of 50% by volume; treat for 3 hours at 20 MPa by a jet cavitation method.

[0043] Step 2: Centrifuge the molybdenum disulfide dispersion at a speed of 500 rpm for 45 minutes, and then transfer the supernatant to a plastic container.

[0044] Step 3: Slowly pour the supernatant into a liquid nitrogen container, and at the same time stir it with a glass rod to form a frozen powder.

[0045] Step 4: Transfer the processed frozen powder into a plastic container, quickly place it in the freezer of an ordinary refrigerator, and store it at a temperature of about -24°C.

[0046] Step 5: When in use, transfer the frozen powder to normal temperature to thaw to form a two-dimensional nanomolybdenum disulfide dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com