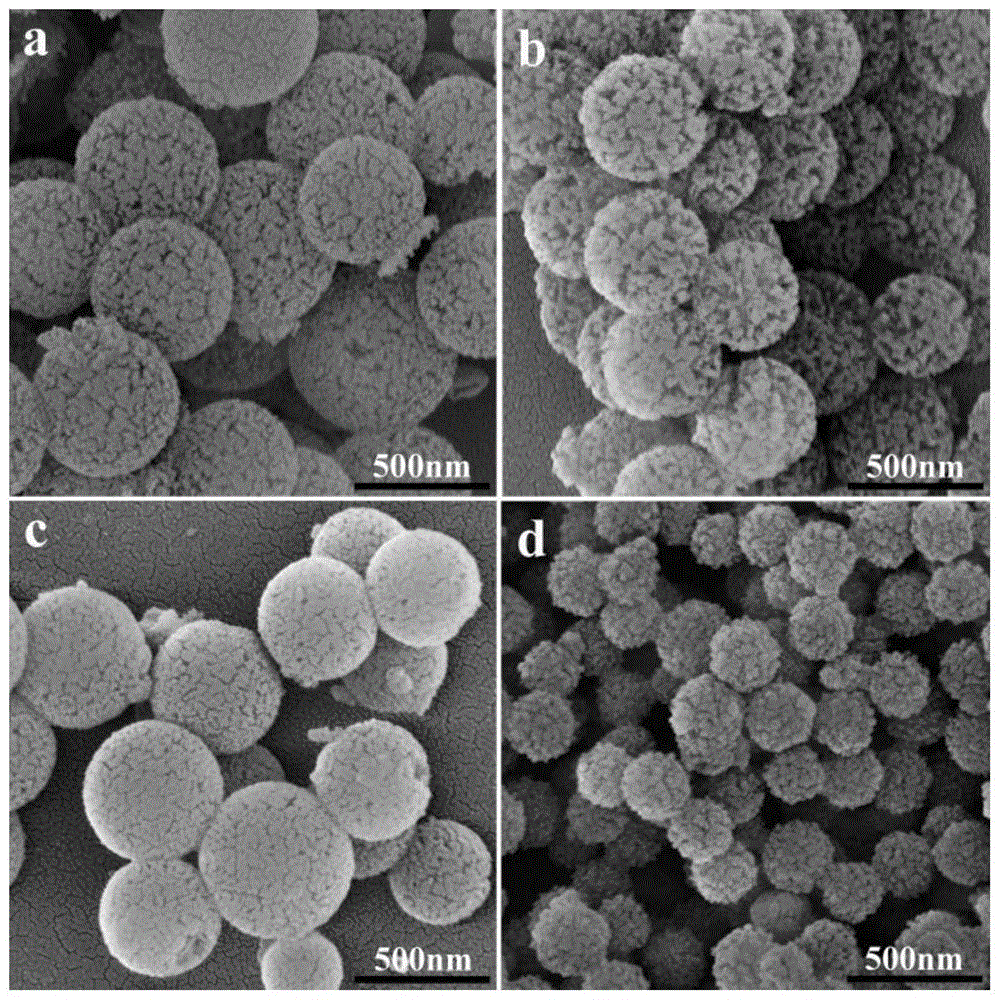

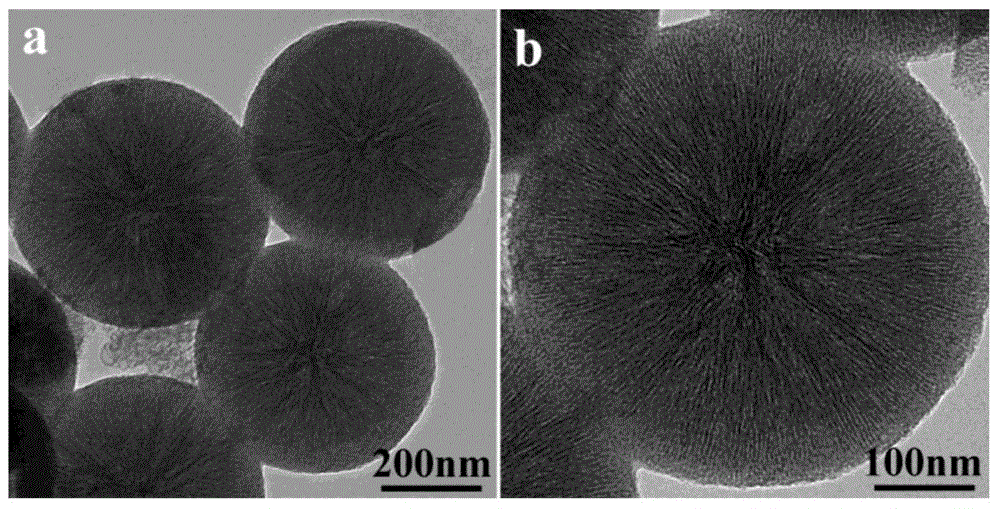

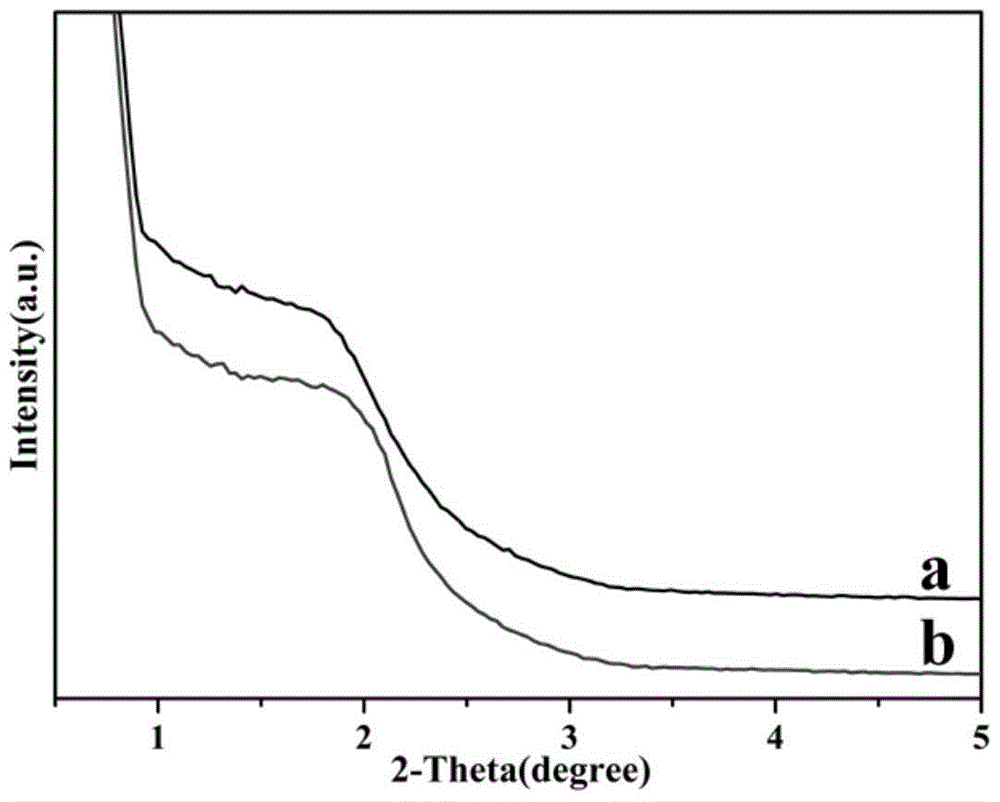

A highly ordered radial spherical wrinkled mesoporous silica material and its preparation method

A silica, highly ordered technology, applied in the field of highly ordered radial spherical wrinkled mesoporous silica material and its preparation, to achieve the effects of large adsorption capacity, high selectivity and fast adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Disperse 0.5 g of TEOS in 4 mL of cyclohexane solution at room temperature;

[0033] (2) At room temperature, add 0.08g of CTAB into a mixed solution of 25mL distilled water and 15mL ethanol, and keep stirring until a transparent solution is formed;

[0034] (3) Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution;

[0035] (4) Add 0.5 mL of ammonia water to the mixed solution obtained in step (3), and continue to stir and react at 35° C. for 4 h;

[0036] (5) the mixed solution that step (4) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 100mL;

[0037] (6) Tighten the autoclave in step (5) and put it in an oven, and cool the autoclave to room temperature naturally after solvothermal reaction at 100° C. for 12 hours;

[0038] (7) Centrifuge the precipitate in step (6), wash it with distilled ...

Embodiment 2

[0042] (1) Disperse 0.5 g of TEOS in 4 mL of cyclohexane solution at room temperature;

[0043] (2) Add 0.08g of CTAB and 0.2g of PVP into a mixed solution of 25mL distilled water and 15mL ethanol, and keep stirring until a transparent solution is formed;

[0044] (3) Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution;

[0045] (4) Add 0.5 mL of ammonia water to the mixed solution obtained in step (3), and continue to stir and react at 35° C. for 4 h;

[0046] (5) the mixed solution that step (4) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 100mL;

[0047] (6) Tighten the autoclave in step (5) and put it in an oven, and cool the autoclave to room temperature naturally after solvothermal reaction at 100° C. for 12 hours;

[0048] (7) Centrifuge the precipitate in step (6), wash it with distilled wat...

Embodiment 3

[0052] (1) Disperse 0.5 g of TEOS in 4 mL of cyclohexane solution at room temperature;

[0053] (2) Add 0.08g of CTAB and 0.4g of PVP into a mixed solution of 25mL distilled water and 15mL ethanol, and keep stirring until a transparent solution is formed;

[0054] (3) Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution;

[0055] (4) Add 0.5 mL of ammonia water to the mixed solution obtained in step (3), and continue to stir and react at 35° C. for 4 h;

[0056] (5) the mixed solution that step (4) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 100mL;

[0057] (6) Tighten the autoclave in step (5) and put it in an oven, and cool the autoclave to room temperature naturally after solvothermal reaction at 100° C. for 12 hours;

[0058] (7) Centrifuge the precipitate in step (6), wash it with distilled wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com