A kind of antistatic ABS composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of composite materials, can solve the problems of limitations and inability to fully utilize antistatic agents, and achieve the effect of uniform distribution and good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

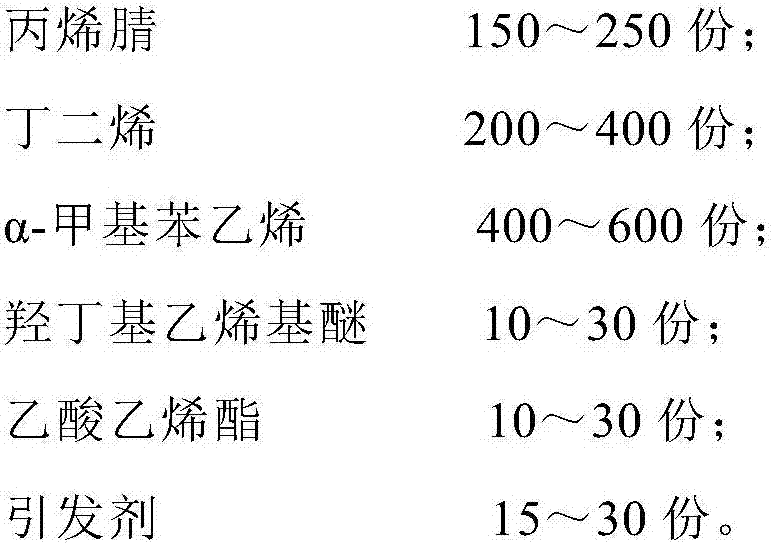

Method used

Image

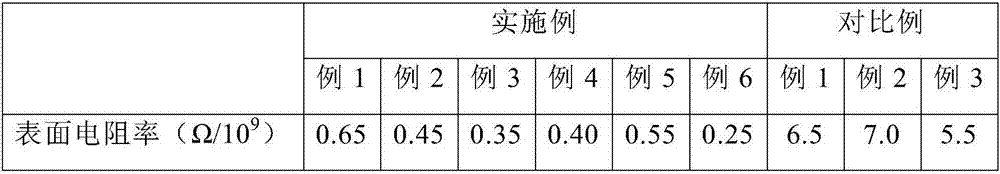

Examples

Embodiment 1

[0026] (1) 150 parts of acrylonitrile, 400 parts of α-methylstyrene, 10 parts of hydroxybutyl vinyl ether and 10 parts of initiator azobisisobutyronitrile, 1000 parts of deionized water, 250 parts Parts of emulsifier nonylphenol polyoxyethylene ether was added to Reactor 1, and under continuous stirring and nitrogen gas flow, the temperature of the system was raised to 70°C and reacted for 4 hours to obtain Latex 1;

[0027] (2) 400 parts of butadiene, 30 parts of vinyl acetate and 10 parts of initiator benzoyl peroxide, 1000 parts of deionized water, 150 parts of emulsifier nonylphenol polyoxyethylene ether are added to In the reactor 2, under the condition of continuous stirring and continuous feeding of nitrogen gas, the temperature of the system was raised to 70° C., and the reaction was carried out for 4 hours to obtain the latex 2 .

[0028] (3) After latex 1 and latex 2 are mixed, they are added to reactor 3, and 10 parts of initiator diisopropyl azodicarboxylate is add...

Embodiment 2

[0030] (1) 200 parts of acrylonitrile, 500 parts of α-methylstyrene, 20 parts of hydroxybutyl vinyl ether and 5 parts of initiator azobisisobutyronitrile, 1500 parts of deionized water, 300 parts Parts of emulsifier sodium dodecylbenzene sulfonate was added to reactor 1, under the condition of continuous stirring and continuous feeding of nitrogen gas, the temperature of the system was raised to 80°C, reacted for 3 hours, and latex 1 was obtained;

[0031] (2) 200 parts of butadiene, 20 parts of vinyl acetate and 5 parts of initiator azobisisobutyronitrile, 1500 parts of deionized water, 250 parts of emulsifier sodium dodecylbenzenesulfonate Put it into the reactor 2, raise the temperature of the system to 80° C. under the condition of continuous stirring and continuous feeding of nitrogen, and react for 3 hours to obtain the latex 2.

[0032] (3) After mixing Latex 1 and Latex 2, add them to Reactor 3, add 5 parts of initiator azobisisobutyronitrile, and heat up to 80°C for p...

Embodiment 3

[0034] (1) 250 parts of acrylonitrile, 400 parts of α-methylstyrene, 30 parts of hydroxybutyl vinyl ether and 5 parts of initiator azobisisobutyronitrile, 2000 parts of deionized water, 350 parts Parts of emulsifier hexadecyltrimethylammonium chloride was added to reactor 1, under continuous stirring and continuous feeding of nitrogen gas, the temperature of the system was raised to 90°C, reacted for 2 hours, and latex 1 was obtained;

[0035] (2) With 300 parts of butadiene, 10 parts of vinyl acetate and 5 parts of initiator benzoyl peroxide, 1200 parts of deionized water, 200 parts of emulsifier hexadecyl trimethyl chloride Ammonium was added to reactor 2, and the temperature of the system was raised to 90° C. under continuous stirring and nitrogen gas flow, and reacted for 2 hours to obtain latex 2.

[0036](3) After latex 1 and latex 2 are mixed, join in the reactor 3, add the initiator benzoyl peroxide of 10 parts, under continuous agitation and continuously feed nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com