Nano antimicrobial plastic and preparation method thereof

An antibacterial plastic and nano technology, applied in the field of nano antibacterial plastic and its preparation, can solve the problems of easy contamination and health hazards, and achieve the effects of stable antibacterial performance, high physical strength and good inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

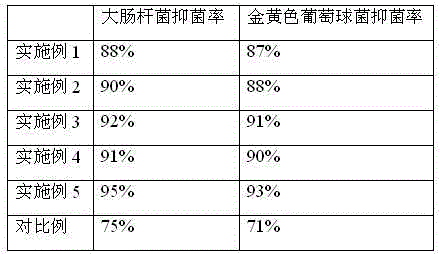

Examples

Embodiment 1

[0043] (1) Take 6 parts by weight of nano-zinc oxide, 4 parts of nano-titanium dioxide, 2 parts of ammonium dihydrogen phosphate, 2 parts of hydroxypropyltrimethylammonium chloride chitosan, and 25 parts of polyvinyl chloride , 6 parts of diethyl phthalate, 2 parts of chlorinated paraffin, 8 parts of polyamide resin, and 10 parts of polyisobutylene. The above components are mechanically mixed first, and mixed until the above-mentioned components are evenly mixed; (2 ) The materials in the step (1) after mechanically mixing uniformly are melted and extruded with a twin-screw extruder. It is divided into 3 sections: the temperature of the first section is 190°C, the temperature of the second section is 210°C, and the temperature of the third section is 230°C; (3) Wait for the material after twin-screw extrusion to cool before pelletizing, and after pelletizing, it is Prepared nano antibacterial plastics.

Embodiment 2

[0045] (1) Take 2 parts by weight of nano-zinc oxide, 1 part of nano-titanium dioxide, 5 parts of ammonium dihydrogen phosphate, 5 parts of hydroxypropyltrimethylammonium chloride chitosan, and 36 parts of polyvinyl chloride , 2 parts of diethyl phthalate, 5 parts of chlorinated paraffin, 18 parts of polyamide resin, and 5 parts of polyisobutylene. The above ingredients are mechanically mixed first, and mixed until the above ingredients are mixed evenly; (2 ) The materials in the step (1) after mechanically mixing uniformly are melted and extruded with a twin-screw extruder. It is divided into 3 stages: the temperature of the first stage is 175°C, the temperature of the second stage is 205°C, and the temperature of the third stage is 220°C; (3) Wait for the material after twin-screw extrusion to cool before pelletizing. After pelletizing, it is Prepared nano antibacterial plastics.

Embodiment 3

[0047] (1) Take 3 parts by weight of nano-zinc oxide, 3 parts of nano-titanium dioxide, 3 parts of ammonium dihydrogen phosphate, 4 parts of hydroxypropyltrimethylammonium chloride chitosan, and 28 parts of polyvinyl chloride , 5 parts of diethyl phthalate, 3 parts of chlorinated paraffin, 10 parts of polyamide resin, and 9 parts of polyisobutylene. The above components are mechanically mixed first, and mixed until the above-mentioned components are mixed evenly; (2 ) The materials in the step (1) after mechanically mixing uniformly are melted and extruded with a twin-screw extruder. It is divided into 3 sections: the temperature of the first section is 190°C, the temperature of the second section is 210°C, and the temperature of the third section is 230°C; (3) Wait for the material after twin-screw extrusion to cool before pelletizing, and after pelletizing, it is Prepared nano antibacterial plastics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com