Preparation method of double-layer composite film

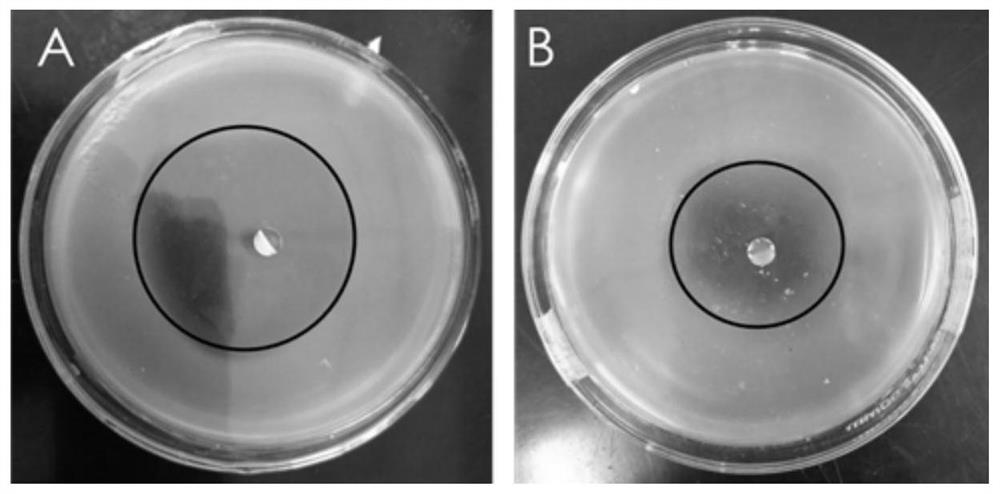

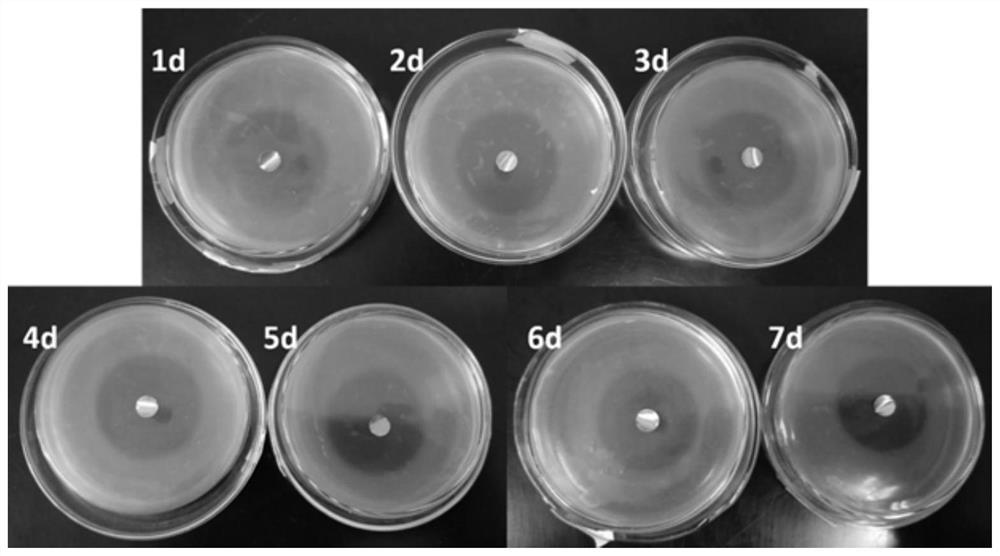

A double-layer composite, thin-film technology, applied in coating, metal material coating process, vacuum evaporation plating and other directions, can solve the problems of unsustainable drug concentration, poor bacteriostatic durability, limited drug loading, etc., to avoid Bacterial adhesion, stable antibacterial properties, avoidance of contamination and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

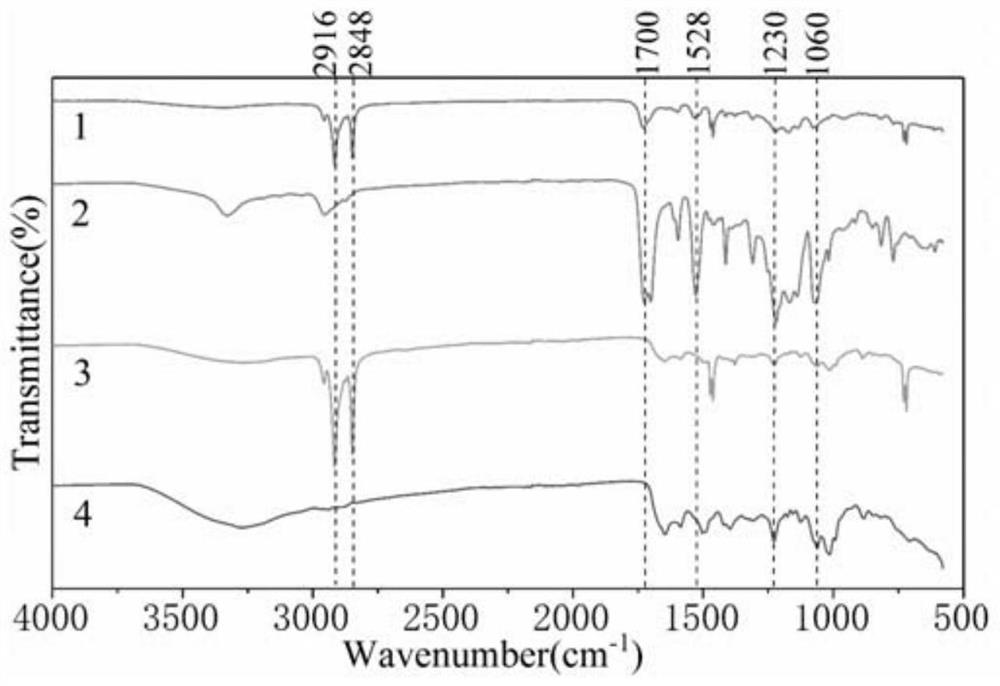

[0030] Take 1*1cm titanium slice and silicon slice respectively, put them in ethanol and ultrasonically clean them for 15 minutes, then wash them with molecular water, repeat the above cleaning steps 3 times, seal the small beakers containing the titanium slices and silicon slices with plastic wrap and put them in Dry in a muffle furnace. Place the dried titanium sheet, silicon sheet and KBr salt sheet prepared in advance in the electron beam deposition chamber, fix the substrate with clips, and deposit PLA:CIP / PU:paraffin:vancomycin composite film ,Specific steps are as follows:

[0031] (1) Deposition of PLA-based ciprofloxacin antibacterial film

[0032] Put the target material with a mass ratio (PLA:CIP=1:1) into the reaction chamber of electron beam deposition, and use the mechanical pump and the molecular pump to evacuate the vacuum respectively to make the vacuum degree reach 6×10 -3 ~8×10 -3 Pa. Turn on the power supply of the deposited film, adjust the working cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com