Preparation method of environment-friendly white carbon black

A technology of silica and environmental protection, which is applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problems that the physical properties of vulcanized rubber cannot reach the best state, and cannot force silica to disperse, etc., to achieve The effect of lowering the temperature, fast powder consumption, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Environment-friendly white carbon black modifier formula:

[0024] The first component: sodium hydroxide 0.041, sodium salicylate 0.022, deionized water 26.

[0025] The second component: divinylpyridine-styrene-butadiene copolymer latex 25.6 (solid content 50%), deionized water 30, ammonia water 3.4.

[0026] Basic formula of glue:

[0027] Natural rubber 100, ZnO10, stearic acid 2, antioxidant (AO-20) 2, commercial silica 65, sulfur 2.5, CZ0.4, accelerator (DM) 1.

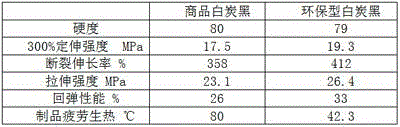

[0028] Environmentally friendly white carbon black was used to prepare compound rubber on an experimental double-roll mill, and the speed ratio of the rollers was 1:1.42; according to the selected formula, rubber, small materials (referring to CZ, DM, ZnO, stearic acid and AO -20), white carbon black and vulcanized rubber are mixed in the order of feeding, and after the film is produced, 2mm thick sheet material samples are prepared by vulcanizing 25t of flat vulcanized rubber according to the positive c...

Embodiment 2

[0031] Environment-friendly white carbon black modifier formula:

[0032] The first component: sodium hydroxide 0.015, sodium salicylate 0.2, deionized water 25.

[0033] The second component: divinylpyridine-styrene-butadiene copolymer latex 100 (solid content 50%), deionized water 80, ammonia water 12.4.

[0034] Basic formula of glue:

[0035] Natural rubber 100, ZnO10, stearic acid 2, antioxidant (AO-20) 2, silica 65, sulfur 2.5, CZ0.4, accelerator (DM) 1.

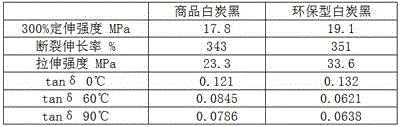

[0036] Environmentally friendly white carbon black was used to prepare compound rubber on an experimental double-roll mill, and the speed ratio of the rollers was 1:1.42; according to the selected formula, rubber, small materials (referring to CZ, DM, ZnO, stearic acid and AO -20), environment-friendly white carbon black and vulcanized rubber are mixed in the order of feeding, after the sheet is produced, use 25t flat vulcanized rubber to vulcanize according to the normal curing time to prepare a 2mm thick sheet mate...

Embodiment 3

[0039] Environment-friendly white carbon black modifier formula:

[0040] The first component: sodium hydroxide 0.035, sodium salicylate 0.1, deionized water 35.

[0041] The second component: divinylpyridine-styrene-butadiene copolymer latex 100 (solid content 50%), epoxidized natural rubber latex 20, deionized water 150, ammonia water 15.8.

[0042] Basic formula of glue:

[0043] Natural rubber 100, ZnO10, stearic acid 2, antioxidant (AO-20) 2, silica 65, sulfur 2.5, CZ0.4, accelerator (DM) 1.

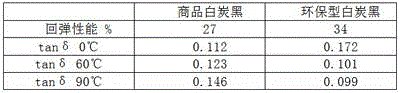

[0044] Environmentally friendly white carbon black was used to prepare compound rubber on an experimental double-roll mill, and the speed ratio of the rollers was 1:1.42; according to the selected formula, rubber, small materials (referring to CZ, DM, ZnO, stearic acid and AO -20), white carbon black and vulcanized rubber are mixed in the order of feeding, and after the film is produced, 2mm thick sheet material samples are prepared by vulcanizing 25t of flat vulcanized rubber acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com