Production method for high-grade naphthenic transformer oil

A technology of transformer oil and production method, which is applied in the direction of base material, petroleum industry, lubricating composition, etc., can solve the problems of poor anti-gassing performance, poor solubility performance, low content of aromatics, etc., and achieve good solubility performance, electrical performance and Good anti-gassing performance and excellent anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

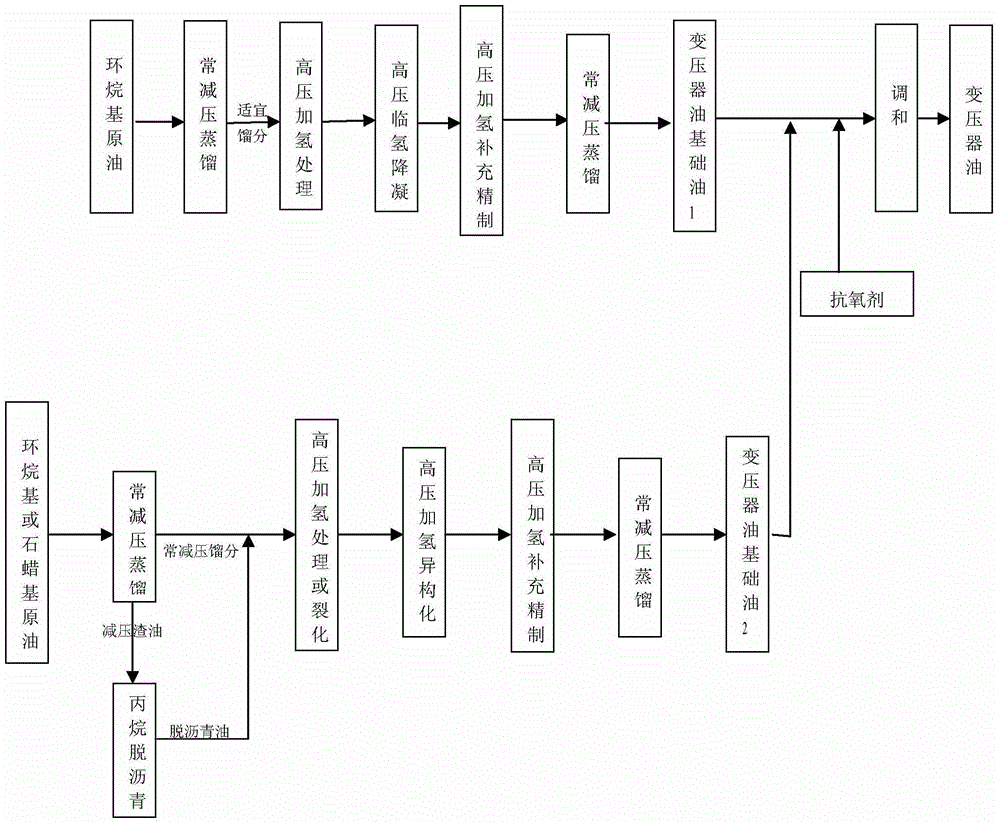

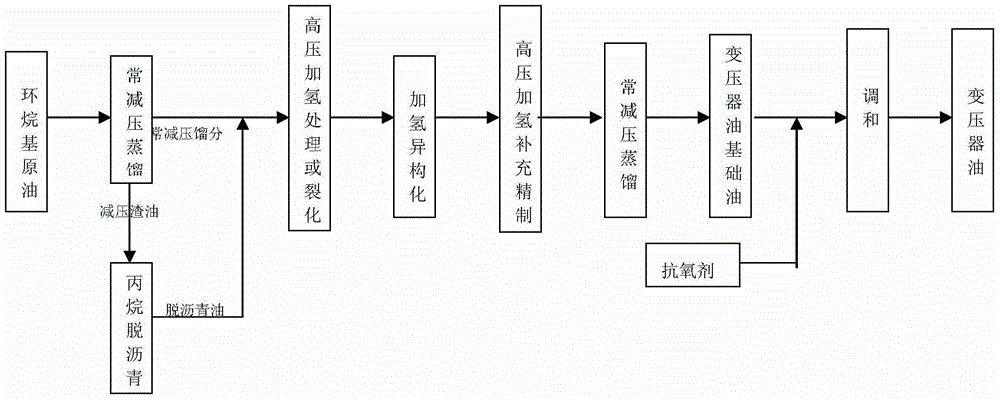

Embodiment 1

[0019] Using the atmospheric and vacuum distillate of naphthenic crude oil as raw material, the base oil A obtained by adopting the combined process of "high pressure hydrotreating-high pressure hydrogen decondensation-high pressure hydrogenation supplementary refining-distillation"; using naphthenic crude oil propane deasphalting Oil is used as raw material, and the combined process of "high-pressure hydrocracking-high-pressure hydroisomerization-high-pressure hydrogenation supplementary refining-distillation" is used to obtain base oil C; base oil A and base oil C are blended at a ratio of 20:80, and then added 0.35% 2,6-di-tert-butyl-p-cresol (DBPC) antioxidant is blended to obtain high-grade transformer oil.

[0020] The transformer oil complies with the I-30°C transformer oil (special) index requirements in the GB2536-2011 and IEC60296-2012 standards, with a gas evolution of +34μL / min, aniline point of 83.8°C, and carbon type analysis of C P The value is less than 50%, wh...

Embodiment 2

[0022] Using the atmospheric and vacuum distillate of naphthenic crude oil as raw material, the base oil B obtained by adopting the combined process of "high pressure hydrotreating-high pressure hydrodecondensation-high pressure hydrogenation supplementary refining-distillation"; using the vacuum distillate of paraffinic crude oil as Raw materials, using the combined process of "high-pressure hydrocracking-high-pressure hydroisomerization-high-pressure hydrogenation supplementary refining-distillation" to obtain base oil D; base oil B and base oil D are blended at a ratio of 50:50, and then 0.35% The 2,6-di-tert-butyl-p-cresol (DBPC) antioxidant is blended to obtain high-grade transformer oil.

[0023] The transformer oil complies with the I-30°C transformer oil (special) index requirements in the GB2536-2011 and IEC60296-2012 standards, the gas evolution is +29μL / min, the aniline point is 82.9°C, and the carbon type analysis is C P The value is less than 50%, which has good s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| aniline point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com