Yeast recovery technology in ultrahigh-concentration ethanol fermentation process

A technology of ethanol fermentation and concentration, applied in fermentation and other directions, can solve the problem of no in-depth discussion on the reuse of yeast surfactants, and achieve the effects of protecting the survival rate of yeast cells, reducing production costs, and improving fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

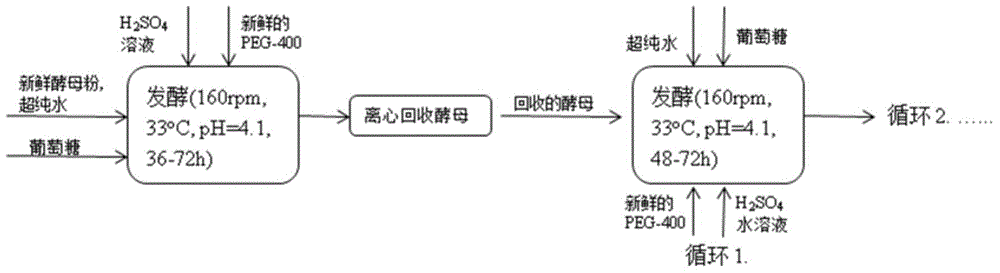

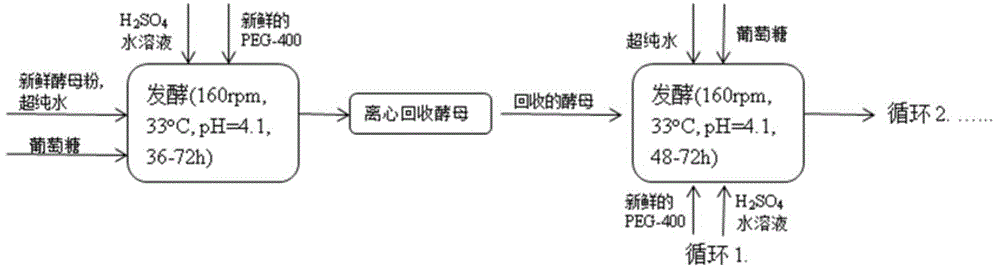

Method used

Image

Examples

Embodiment 1

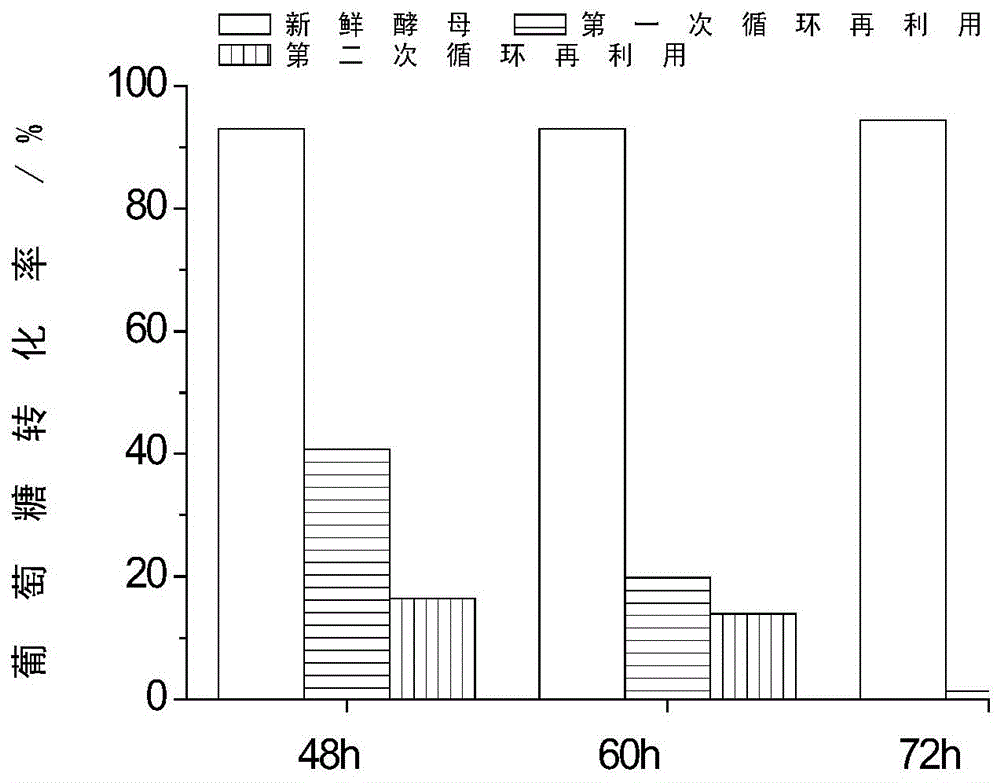

[0026] Rehydrate 0.5g of yeast powder with 4mL of ultrapure water at 25-38°C for 15-30 minutes, then add 6.5g of glucose and 12mL of pre-configured sulfuric acid solution with a pH value of 4.8, and place it in a shaker for shaking. Ferment at 33°C for 48-72 hours. After the fermentation, refrigerate and centrifuge at 8000rpm for 5 minutes, remove the clear night from the fermentation broth after the fermentation, leave solid yeast powder, add 4mL ultrapure water, 6.5g glucose, 12mL sulfuric acid solution, and ferment at 33°C for 48-72 hours, so Cycle 2 times. Glucose conversion rate, ethanol yield and concentration are as follows image 3 , Figure 4 , Figure 5 shown. It can be seen from the data in the figure that when no surfactant is added to the fermentation system, the recovery efficiency of yeast is very low. After 48 hours of fermentation, the recovered yeast can only be recycled for the first time to obtain 60g.L -1 ethanol concentration.

Embodiment 2

[0028] Rehydrate 0.5g of yeast powder with 4mL of ultrapure water for 15-30 minutes at 25-38°C, then add 6.5g of glucose, PEG-4004.0g, and 12mL of a pre-prepared sulfuric acid solution with a pH value of 4.8, and put it in a shaker Shake in the bed, and ferment for 72 hours at 33°C. After the fermentation, refrigerate and centrifuge at 8000rpm for 5 minutes, remove the clear night from the fermentation broth after the fermentation, leave solid yeast powder, add 4mL ultrapure water, 6.5g glucose, 4.0g PEG-400, 12mL sulfuric acid solution, and ferment at 33°C 48 hours, so cycle 3 times. Glucose conversion rate, ethanol yield and concentration are as follows Figure 6 , Figure 7 , Figure 8 shown. It can be seen from the data in the figure that when PEG-400 is added to the fermentation system, the yeast recovery efficiency is very high. After 48 hours of fermentation, the recovered yeast can be recycled for the first time to obtain 118g.L -1 ethanol concentration.

Embodiment 3

[0030] Rehydrate 0.5g of yeast powder with 4mL of ultrapure water for 15-30 minutes at 25-38°C, then add 7.5g of glucose, 4.0g of PEG-400, and 12mL of pre-configured sulfuric acid solution with a pH value of 4.8, and put Vibrate in a shaker, and ferment for 72 hours at 33°C. After fermentation, refrigerate and centrifuge at 8000rpm for 5 minutes, remove solid yeast powder, distill the supernatant, and the residue after distillation enters the next fermentation process, add 0.5g yeast powder again and use 4mL ultrapure water Rehydrate for 15-30 minutes, 6.5g glucose, 12mL sulfuric acid solution, ferment at 33°C for 72 hours, and cycle like this 4 times. Glucose conversion rate, ethanol yield and concentration such as Figure 9 It was shown that the surfactant PEG-400 could be recycled and had no significant effect on the fermentation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com