Variable-diameter autoclave for hydrothermal method crystal growth

A technology of crystal growth and hydrothermal method, applied in the field of variable-caliber autoclave, can solve problems such as low crystallization efficiency, slow crystallization, and seed crystal corrosion, achieve good pressure and temperature resistance, precise temperature control, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

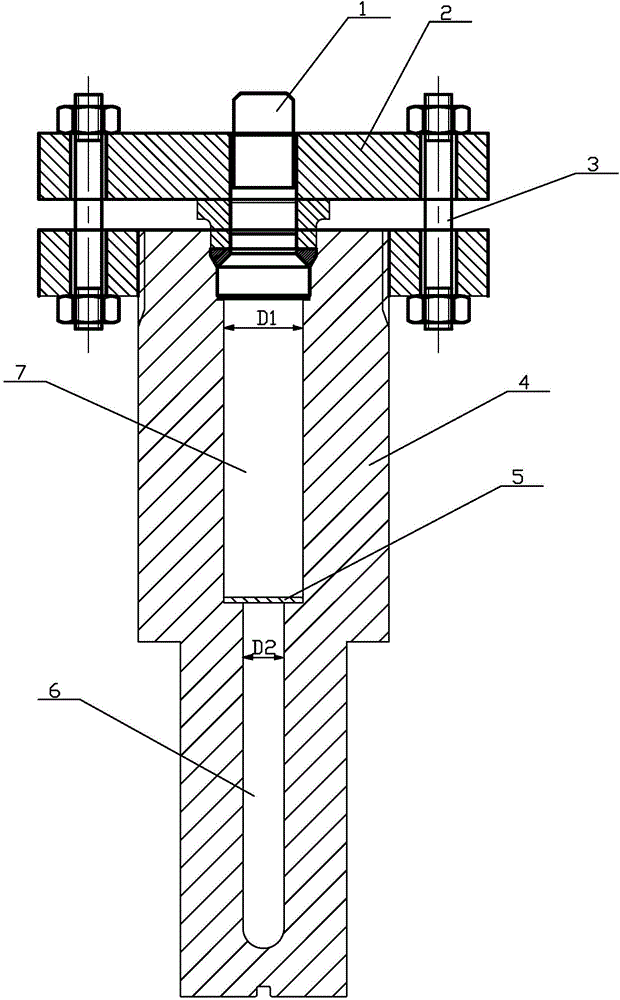

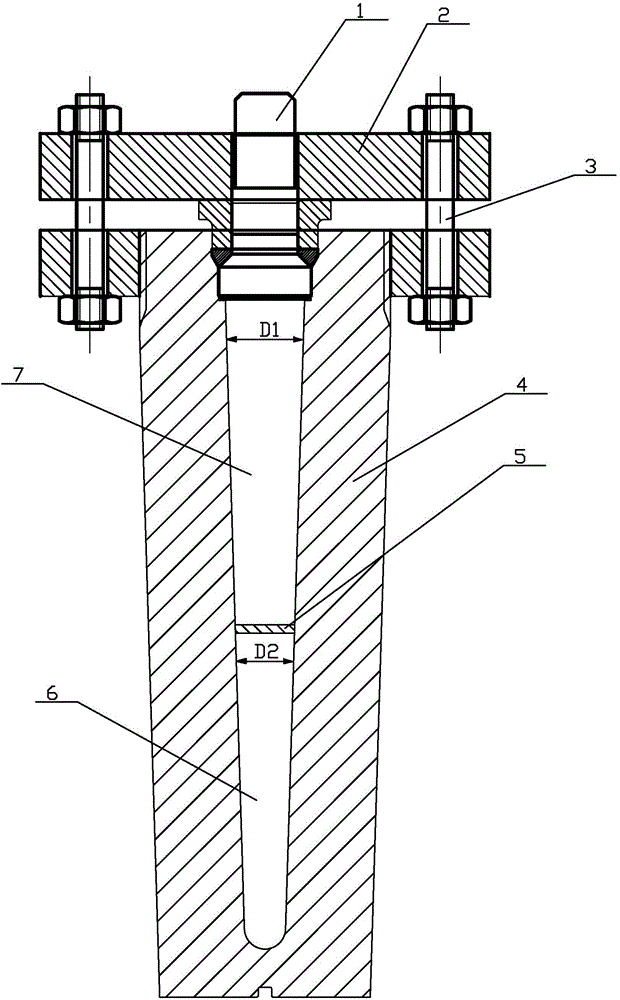

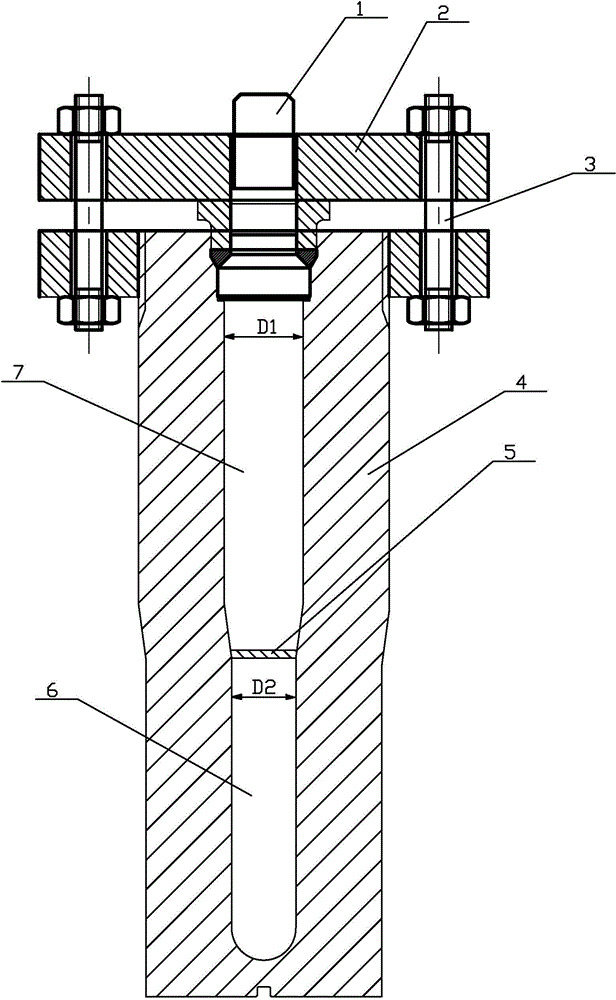

[0027]figure 1 It is an embodiment of the variable-diameter autoclave used for hydrothermal crystal growth according to the present invention. Such as figure 1 As shown, the variable-diameter autoclave used for hydrothermal crystal growth according to the present invention includes a kettle body 4 and a kettle cover 2, and the kettle cover 2 is provided with a self-tightening sealed kettle that cooperates with the opening of the inner cavity of the kettle body 4 The plug 1, the kettle body 4 and the kettle cover 2 are connected by fastening bolts 3 . The inner cavity of the kettle body 4 is divided into a dissolution zone 6 and a crystallization zone 7 by a baffle plate 5, and the diameter D1 of the crystallization zone 7 in the kettle body 4 is greater than the diameter D2 of the dissolution zone 6 in the kettle body 4; wherein the crystallization zone 7 is located above the dissolution zone 6, the shape of the crystallization zone 7 is a columnar structure, that is, the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com