Hybrid reliability testing method for marine mechanical and electrical products

A technology of electromechanical products and test methods, applied in the direction of measuring devices, instruments, etc., can solve the problems of lack of theoretical basis and calculation method of data reliability, poor reliability of test results, and difficulty of simulation technology, so as to reduce the number of simulation tests. Time and stress conditions are true and reliable, and the effect of saving test costs

Active Publication Date: 2015-06-10

NAVAL UNIV OF ENG PLA

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

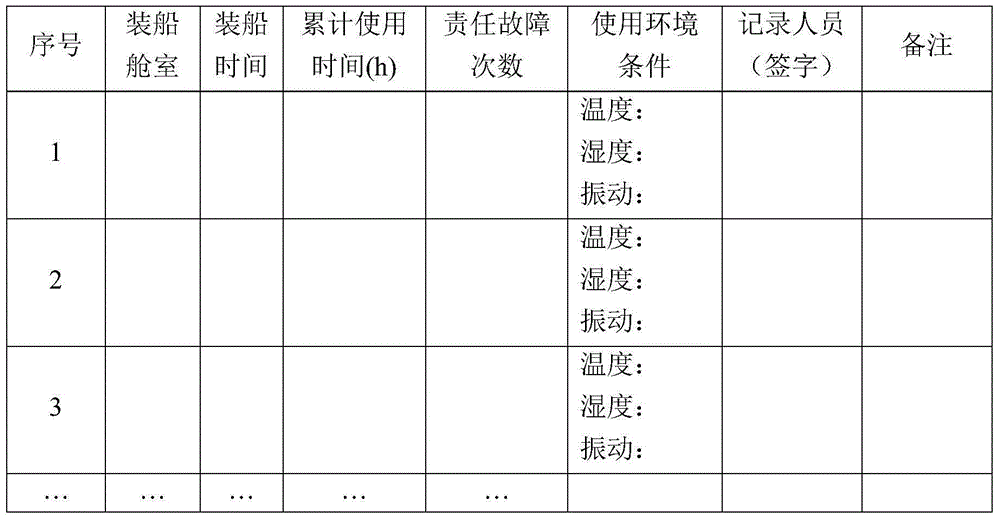

[0008] The present invention is aimed at the existing technical difficulty, high cost, long test cycle, and poor reliability of the test results when using laboratory simulation tests or field tests for marine electromechanical products in the prior art, and the use of data existing in use tests Due to the lack of theoretical basis and calculation methods for reliability and equivalent conversion, a hybrid reliability test method that combines laboratory simulation tests and use tests is proposed, and some products are shipped and used as use tests. In the process, some products are subjected to laboratory simulation tests, and then the two parts of the test data are converted and synthesized according to the equivalent coefficient to obtain the final test data, which not only saves the expensive cost of laboratory simulation of complex stress conditions, but also can truly reflect the stress conditions of the actual use state , to ensure the credibility of the test, and also significantly shorten the test cycle, save time and cost, and reduce the consumption of human, material and financial resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

test approach 21

[0065] For this test, due to the large size of the tested product, high unit cost, small number of samples, and tight test time, etc., the standard test scheme 21 was selected according to the requirements of GJB899-2009, and its parameter α = β = 30%, d = 3.0.

[0066] (2) Selection of test time parameters

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a hybrid reliability testing method for marine mechanical and electrical products. The hybrid reliability testing method for the marine mechanical and electrical products combines laboratory simulation test with use test, some products are used for shipment, the total reliability of service data meets a specified requirement, some products perform laboratory simulation test, the test data of the products are converted and synthesized according to equivalent coefficients to obtain the final test data, the expensive cost for the laboratory for simulating complex stress conditions is lowered, the stress condition of the actual use state can be really reflected, the test reliability is guaranteed, the test period is obviously shortened, the time cost is saved, the manpower, material resource and financial resource consumption is reduced, and the test benefit is obviously improved; the hybrid reliability testing method for the marine mechanical and electrical products is especially suitable for the marine mechanical and electrical products difficult to perform conventional reliability simulation test and products which are used for ships without performing reliability test.

Description

technical field [0001] The invention relates to a reliability test method for marine electromechanical products, in particular to a hybrid reliability test method for marine electromechanical products, which belongs to the technical field of reliability tests. Background technique [0002] Reliability testing is an indispensable means to improve product design, evaluate and assess various quality characteristics of products in the process of product development. At home and abroad, at the beginning of product development, it is necessary to fully analyze the product life cycle profile and environmental profile, basic characteristics, On the basis of available resources such as similar equipment, time and cost, formulate a complete reliability test plan, and implement it at each stage of product development, give full play to the role of reliability test, and develop high-quality products in a timely and rapid manner. In the prior art, the reliability test generally adopts la...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01D21/00

Inventor 吕建伟陈霖谢宗仁徐一帆杨春辉杨建军

Owner NAVAL UNIV OF ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com