Automatic shrinkage rate adjustment system and method of clothing pattern

A paper pattern and automatic technology, applied in the field of garment processing, can solve the problems of long production cycle and low work efficiency, and achieve the effect of improving work efficiency and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

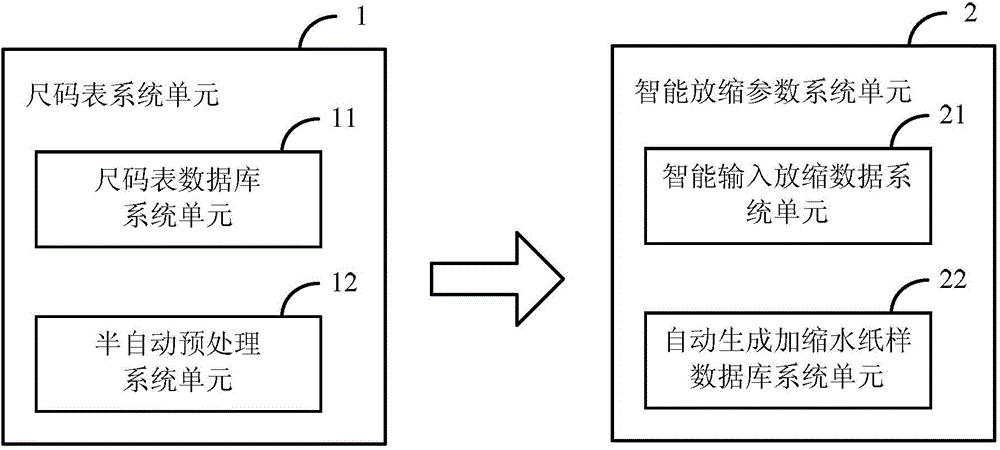

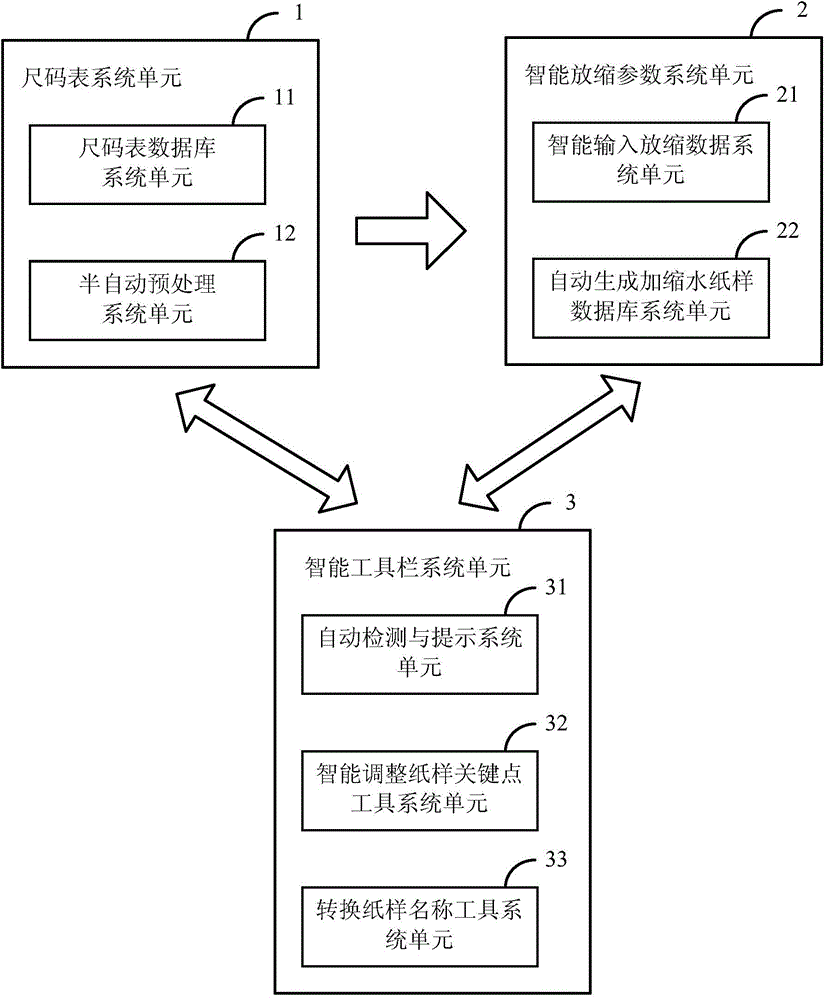

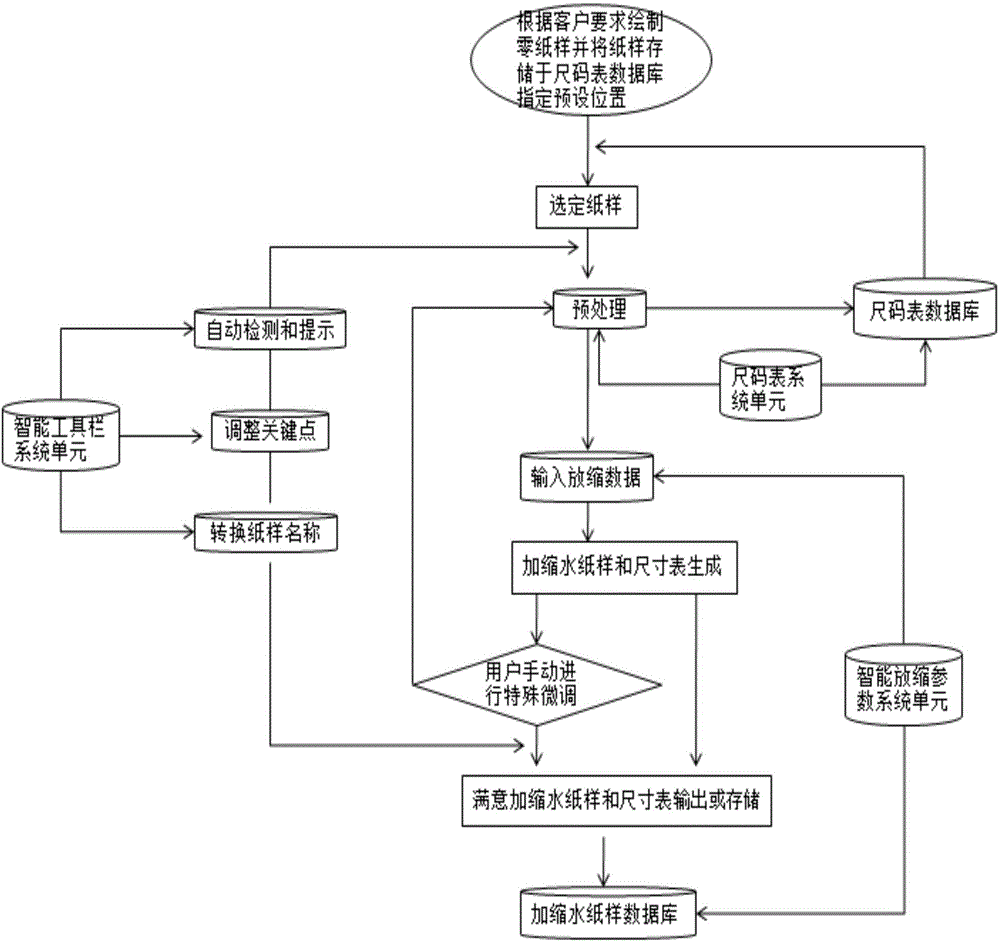

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: Not all patterns need to adjust the weft skew, and the weft skew of the paper pattern is mostly used in knitted fabrics and mainly used on the pattern pieces of the front panel, back panel and sleeves. For example, select the front and back samples of the knitted jacket pattern that needs to be adjusted and the pretreatment operation has been completed (see Figure 8 ), after entering the value 6° of weft skew and the direction of weft skew in the intelligent input scaling data dialog box, press "OK" to automatically generate shrinkage pattern database system unit will automatically complete the weft skew adjustment of the pattern and generate the adjusted pattern ( see Figure 9 ).

Embodiment 2

[0079] Embodiment 2: Not all patterns need to adjust the twisted bone, and the twisted bone is mostly used in knitted fabrics, woven fabrics, and mainly used on the pattern pieces of the front and back panels of shirts and trousers. For example, select the back panel sample 101, the right front panel sample 102 and the left front panel sample 103 (see Figure 10), after entering the twisted bone value 1 / 2″ and the twisted bone direction in the smart input shrinkage dialog box, press “OK” to automatically generate shrinkage pattern database. The system unit will automatically complete the twisted bone adjustment of the pattern and generate the adjusted Corresponding paper pattern rear sample sheet 101', right front sample sheet 102' and left front sample sheet 103' (see Figure 10 ).

Embodiment 3

[0080] Embodiment 3: Generally speaking, for twill cutting patterns, in the intelligent input scaling data dialog interface, after the user selects "Select Pattern" in the "Longitudinal Grain Angle" drop-down menu, the pattern that needs to be processed with longitudinal grain angle will be automatically displayed The sample piece, and then the user selects a line segment corresponding to the sample piece, and the generated vertical grain angle of the sample piece will be automatically recorded in the "longitudinal grain angle" position and shrinkage is performed according to this data.

[0081] As mentioned above, the garment pattern automatic shrinkage system in the embodiment of the present invention can also be equipped with an intelligent tool bar system unit, including an automatic detection and prompt system unit, an intelligent adjustment pattern key point tool system unit and a pattern name conversion tool system unit. Among them, the automatic detection and prompting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com